30/64 Installation

Bosch Rexroth AG, A15V(L)O Series 11, RE 92511-01-B/2019-10-09

7.3.2 Inside-reservoir installation

NOTICE

Risk of damage with inside-reservoir installation!

To prevent damage to the axial piston unit, all plastic parts (e.g.protective plugs,

covers), except for the tamper-proof caps, must be removed prior to installation in

the reservoir.

▶ Remove all plastic parts, except for the tamper-proof caps, before you install the

axial piston unit in the reservoir. Make sure that no parts of them remain in the

reservoir.

▶ Remove the protective plug from the suction portS and open at least one T port.

Inside-reservoir installation is when the axial piston unit is installed in the reservoir

below the minimum fluid level. The axial piston unit is completely below the

hydraulic fluid.

If the minimum fluid level is equal to or below the upper edge of the pump,

seechapter 7.3.3 "Above-reservoir installation" on page 31.

Axial piston units with electric components (e.g.electric controls, sensors) must

not be installed in a reservoir below the fluid level.

Our advice is to fit a suction pipe to the suction portS and to fit a pipe to drain

port T

1

In T

2

to encase. In this case, the other drain portmust be plugged.

Thehousing of the axial piston unit must be filled before fitting the piping and

filling the reservoir with hydraulic fluid. To prevent draining of the housing,

thereservoir has to be filled with hydraulic fluid as quickly as possible.

4 5

S

h

min

h

t min

T

1

T

2

T

3

SB

T

2

h

t min

T

1

T

3

h

min

SB

S

Fig. 10: Inside-reservoir installation A15VO/A15VLO with installation position 4–5

T

1

,

T

2

,

T

3

Drain port h

t min

Minimum required immersion depth

(200mm)

S Suction port h

min

Minimum required distance to

reservoir bottom (100mm)

SB Baffle (baffle plate)

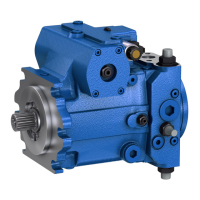

Loading...

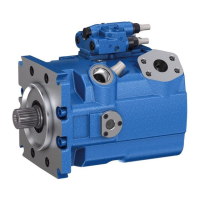

Loading...