8/48 Safety instructions

Bosch Rexroth AG, 4WRPD(H), 4WRPQ(H), 4WRPF(H), 4WRLD, 4WRLF, 4WRLQ, 5WRPF10, 5WRPQ10; RE 29391-B/05.2021

Abbreviation Meaning

PL Performance Level according to EN ISO 13849-1

SELV Separated extra-low voltage

PLC Programmable Logic Control

2 Safety instructions

2.1 About this chapter

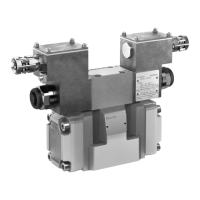

The valves on Multi-Ethernet basis described below have been manufactured

according to good engineering practice. However, there is still a risk of personal

injury and/or damage to property if you do not observe this chapter and the safety

instructions in this documentation.

Read this documentation completely and thoroughly before working with the

product.

Keep this documentation in a location where it is accessible to all users at all

times.

Always include the required documentation when you pass the valve on to third

parties.

2.2 Intended use

A valve on Multi-Ethernet basis is a valve with electrical control for use in two-

channel safety applications (cat. 3, PL d and cat. 4, PL e according to EN 13849-1)

as switch-off element for one channel.

Depending on the application and the requirements of work equipment-related

standards according to EN 13849-1, the user must provide appropriate monitoring/

plausibility checks which comply with the required diagnostic coverage DC

avg

using

a higher-level control.

The valve is exclusively intended for integration into a machine or system or to

be assembled with other components to form a machine or system. The product

may be commissioned only if it is integrated in the machine/system for which it is

designed.

The operating conditions and the performance limits specified in the technical data

sheet must be observed.

The valve on Multi-Ethernet basis may be used as follows:

• For open and closed-loop (alternating) control of position, pressure, force,

velocity, pressure differential and flow

For operation of the device, a higher-level control logic with appropriate I/O

components is additionally required, which, in conjunction with the valve on Multi-

Ethernet basis, holistically controls the motion sequence of the machine and also

monitors it in terms of safety.

Loading...

Loading...