Do you have a question about the Bosch Rexroth 4WS2EM 10 Series and is the answer not in the manual?

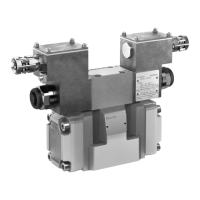

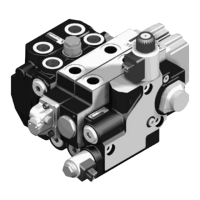

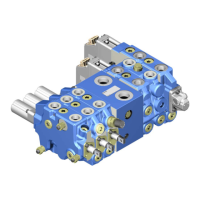

Describes which products this documentation applies to and how to identify the valve type.

Lists related documents, including data sheets and declaration of conformity.

Explains the use of symbols, terms, and abbreviations for clear understanding.

Details how safety instructions are presented with signal words and risk classes.

Explains the meaning of symbols used in the document for better comprehension.

Provides a list of abbreviations commonly used in the documentation.

General advice on reading and keeping the documentation accessible.

Defines the product's purpose and limitations, including for explosive atmospheres.

Lists prohibited uses that deviate from the intended application.

Specifies the required expertise for installation and commissioning.

General rules for safe operation, including regulations and product condition.

Specific warnings for explosion hazards, flammable fluids, and temperature limits.

Lists the necessary personal protective equipment for safe operation.

Defines the responsibilities of the end-user for product compliance and safety.

Details how to identify the product using its name plate information.

Explains explosion protection zones, device groups, and categories for safe use.

Details the temperature classes and their corresponding maximum surface temperatures.

Describes the different types of protection measures against ignition in explosive atmospheres.

Guidelines and precautions for safely transporting the hydraulic valve.

Specifies conditions for proper storage to prevent damage.

Instructions for safely unpacking the product.

Warning against modifying surface protection, which voids explosion protection.

Requirements for environmental conditions and cleanliness during installation.

Checks to perform before starting the assembly process.

Lists the standard tools needed for assembling the valve.

Lists accessories recommended for valve connection.

Detailed steps for assembling the valve components.

Instructions for mounting the valve into the overall system.

Procedures for connecting hydraulic lines and hoses to the valve.

Steps for connecting the electrical power supply to the valve.

Procedure for verifying electrical connections before initial commissioning.

Guidance on checking the hydraulic functions at low pressure.

Ensuring no hydraulic fluid leaks occur during operation.

General guidelines, warnings about dust accumulation and noise.

Instructions for cleaning and maintaining the valve's condition.

General procedures for inspecting and maintaining the valve.

Recommended schedule and checks for ensuring long-term reliability.

Warning against improper repair and guidelines for authorized repairs.

Step-by-step guide for replacing the filter element.

Procedures for fixing external leaks at connection surfaces and filter screws.

Lists available spare parts and their material numbers.

Guidelines for environmentally friendly disposal of the valve and fluid.

Procedure for returning the product to the manufacturer for disposal.

Information on packaging materials used for disposable packaging.

Lists the basic materials that the hydraulic valves consist of.

Information on recycling hydraulic products due to their high metal content.

Systematic approach to identifying and resolving faults in the valve and system.

Contact information for transport damage, repair, spare parts, and sales.

| Category | Control Unit |

|---|---|

| Operating Pressure | 315 bar |

| Housing Material | Aluminum |

| Protection Class | IP65 |

| Series | 10 |

| Flow Rate | 10 l/min |

Loading...

Loading...