6720892984 (2019/02) US SSB

36 | Main control

Frost protection for boiler cascade

The ‘frost protection’ function for a burner cascade is related to the boiler

sensor temperatures.

When the boiler sensor temperature or the managing burner supply/

return temperature is below:

Cascade frost protection

The cascade CH/system pump and the general pump of the managing

burner start running.

Cascade frost protection – 5°C

Cascade heat demand is activated to open the optional air damper, the

general pumps of all the burners will be started. Demand with setpoint

Cascade frost protection allows the burners to start burning until the

lowest of both boiler, managing supply and return temperatures are

above

Cascade frost protection + 5°

C.

Frost protection on burner

As last protection the controllers for the burners can force themselves to

burn.

NOTE: On systems with an air damper this demand will not be served

when the air damper is closed.

If the burner supply/return temperature drops below 5°C (41°F) the

burner starts at minimum power and continues burning until the lowest of

both supply and return temperatures are above 15°C (59°F).

Frost protection in cascades with air damper

To enable frost protection a demand must be generated on the cascade

controller. This is covered by the frost protection and needed because

the air damper must be opened by the cascade controller before a burner

can start.

5.3.8 Flue temperature protection (Rev 3.0.0.0)

The ue temperature protection function protects against the ue gas

reaching too high temperatures. Either a ue gas sensor or a ue switch

can be used.

• When the

T_Flue

or

T_Flue_2

sensor measure above the

Max_

Flue_Gas_Temp

the control generates a

Flue_Gas_Error

.

• When the Flue_Switch closes the control generates a

Flue_Gas_

Error

.

When the control is in a Flue_Gas_Error the fan will run at the minimum

fan speed.

Burner power limitation

When a ue gas sensor is connected the control will limit the burner

power when the ue gas temperature reaches the set

Max_Flue_Gas_

Temp

. The maximum burner power is linearly limited when the ue gas

temperature is within

Max_Flue_Gas_Temp

– 5°C and

Max_Flue_Gas_Temp

.

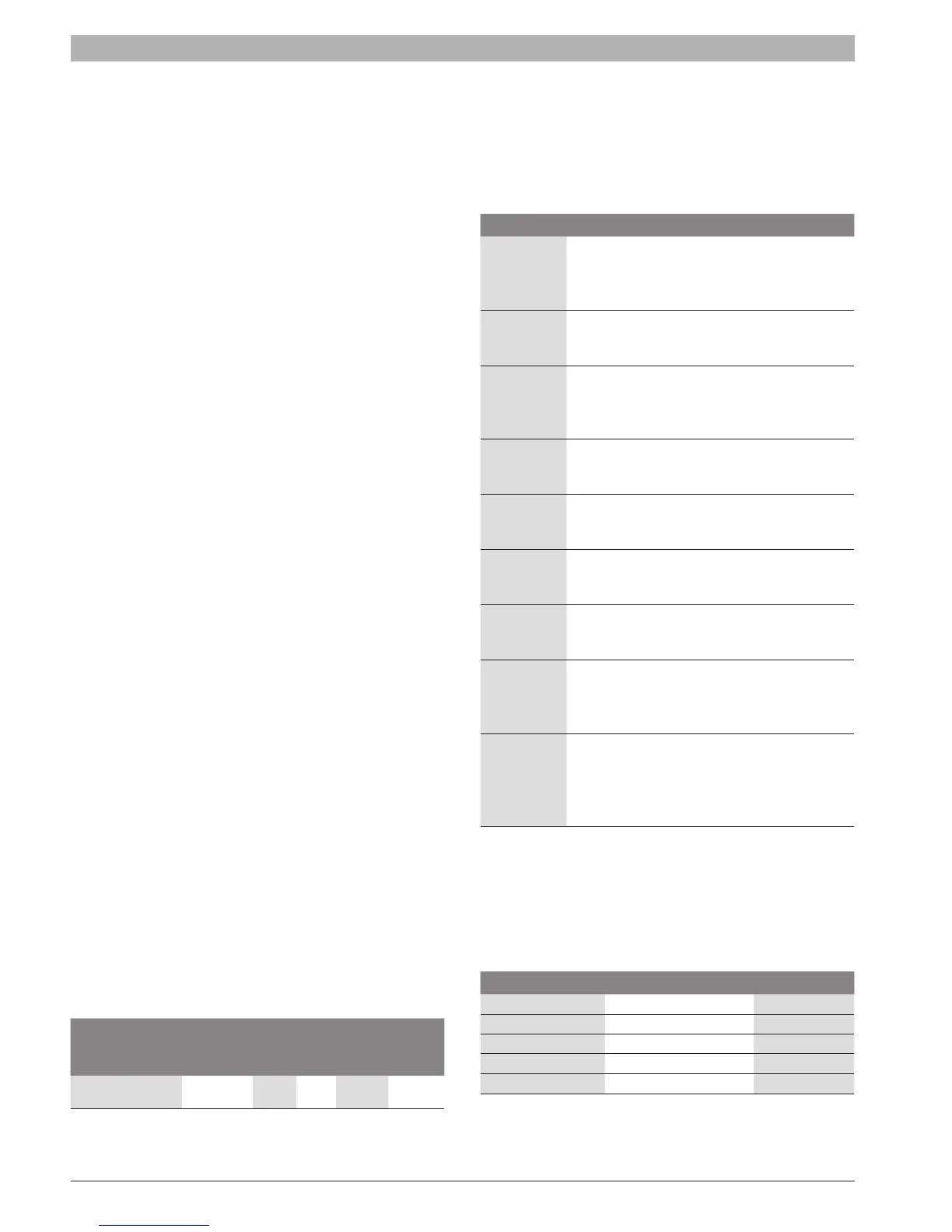

Relevant variables

Specic

Parameters

Level

(Default)

Value

Settable

°C °F °C °F

Max_Flue_Gas_

Temp

[°C/°F]

3: Factory 100 212 40...130 104...266

5.3.9 Input conguration 900MN (Rev 4.0.905.16712)

There are several multiple function inputs that can be applied for different

types of appliances. The function of the input can be selected via the

epHS display but also with LabVision PC software.

The following input functions can be selected:

Input Description

J72-3

0 ¨ Disabled

1 ¨ Water pressure sensor

2 ¨ CH ow switch

3 ¨ Flue pressure switch

J72-4

0 ¨ Disabled

1 ¨ T_DCW sensor

2 ¨ Water pressure switch

J77-8

0 ¨ Disabled

1 ¨ DHW ow sensor

2 ¨ DHW ow switch

3 ¨ CH ow switch

J79-10

0 ¨ Disabled

1 ¨ Drain switch

2 ¨ Gas pressure switch

J123-6(*)

0 ¨ T_Supply_2 sensor

1 ¨ Disabled

2 ¨ Air damper switch

J63-10

0 ¨ Disabled

1 ¨ T_Return sensor

2 ¨ Vapor switch

J64-11

0 ¨ Disabled

1 ¨ T_DHW sensor

2 ¨ T_Zone sensor

J65-12

0 ¨ Disabled

1 ¨ T_Fluesensor

2 ¨ Flueswitch

3 ¨ APSswitch

676-13

0 ¨ Disabled

1 ¨ T_Flue_2 sensor

2 ¨ T_Flue_2 with blocked ue

3 ¨ T_System sensor

4 ¨ Blocked ue switch

(*) Duplex safety sensors cannot be adjusted freely.

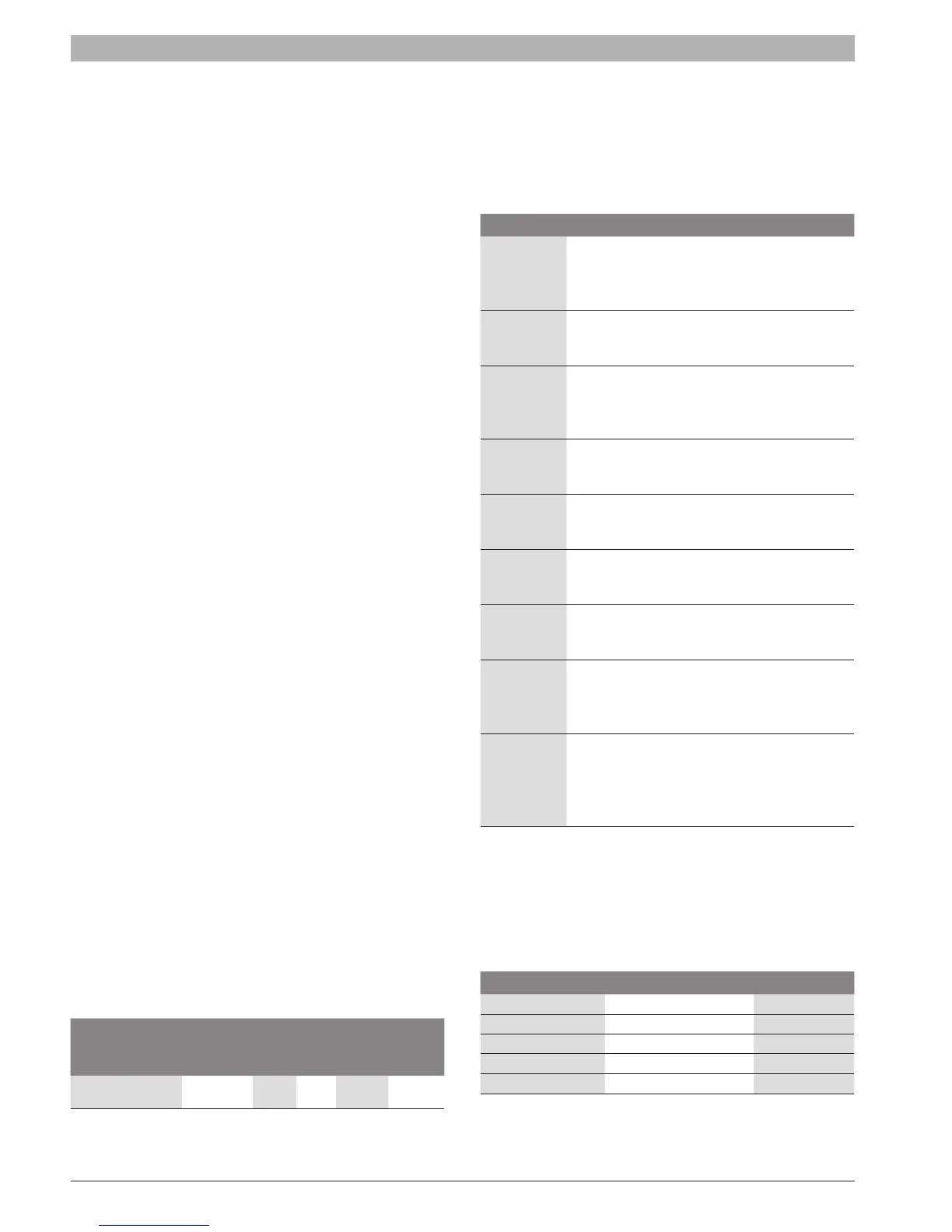

5.3.10 Output conguration 900MN (Rev 4.0.905.16712)

There are several multiple function outputs that can be applied for

different types of appliances. The function of the output can be selected

via the epHS display but also with LabVision PC software.

The following outputs are available on the control:

Output Connection Type output

Prog. Output 1 J3 3-8 Relay output

Prog. Output 2 J3 5-10 Relay output

Prog. Output 3 J3 6 Relay output

Prog. Output 4 J3 1-2-7 Relay output

Prog. Output 5 J3 4-9 Relay output

Loading...

Loading...