BRAY Series 70 Electric Actuator

Operation and Maintenance Manual

15

i.

adjuSt the OPen and clOSe SPeed Of yOur actuatOr

(t

he faSteSt clOSing SPeed Of yOur actuatOr iS

Printed On the label Of the unit):

1. Use the Close Speed trim pot to adjust the closing

speed of your actuator (pot in the fully CCW position

equals fastest close speed).

2. Use the Open Speed trim pot to adjust the opening

speed of your actuator (pot in the fully CCW position

equals fastest open speed).

ii. calibrate the SerVO:

1. Manually position your actuator somewhere in

mid position; away from the travel limits.

2. Disengage your handwheel (push it back in towards

the actuator), hold down the Calibration push button

for two seconds and release, the servo will begin

to drive the actuator in the close direction and then

in the open direction in order to save these limits

to memory.

3. Following a successful calibration the servo’s

Status LED will begin to ash the normal operation

code, an unsuccessful calibration will yield a Red-

Green-Red-Green ash immediately following the

attempted calibration (for more information on the

Status LED ash codes see the Status LED Flash

Code Table).

StatuS led

The “Status LED” is a bi-color LED which provides detailed

information regarding the operation of the S70 Servo Pro.

Table 2 below illustrates the different combinations of LED

ash codes and their corresponding conditions. Following

the table is a more descriptive explanation of the Flash Code.

Whenever the LED is ashing green, regardless of the ash

code, the servo will operate, but not necessarily optimally.

Whenever the LED ash codes are RED, the servo will not

operate. An example is an engaged handwheel, the Status

LED will ash a single red ash code and will not operate.

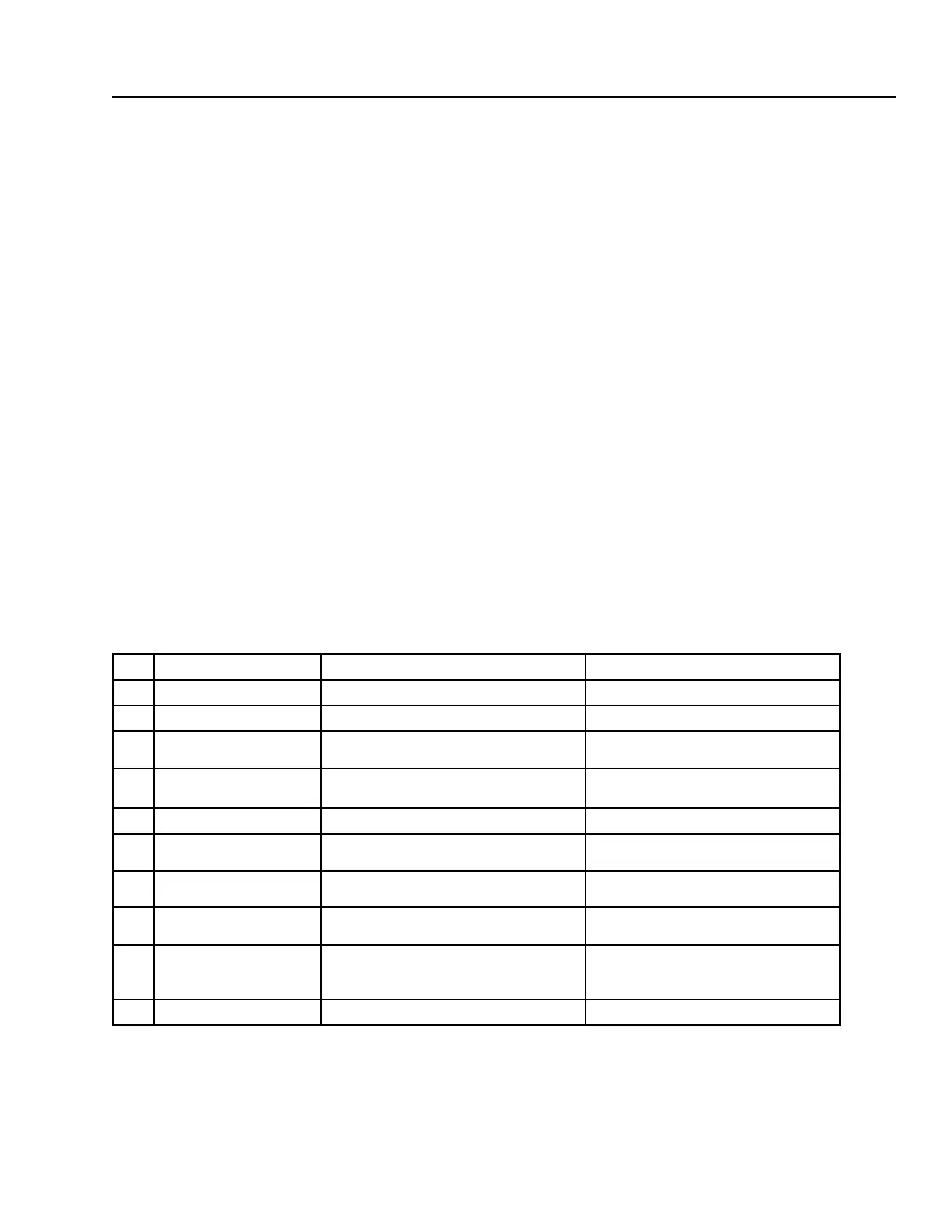

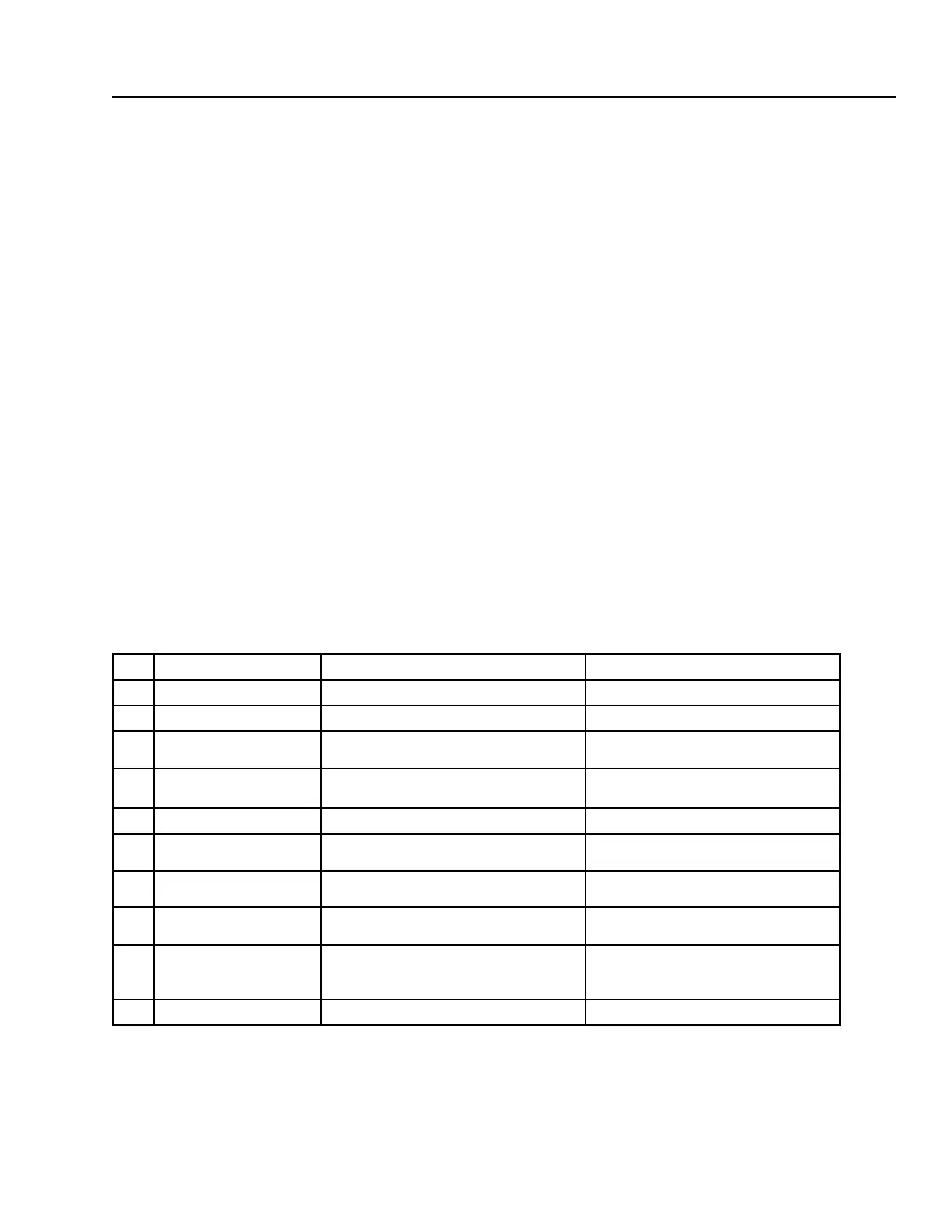

table 2: StatuS led flaSh cOdeS

green StatuS led Warning and infOrMatiOn flaSh cOdeS:

#

indicatiOn reaSOn SOlutiOn

1 Steady Green Flash Normal Operation Servo Functioning Ok

2 2 Green Flashes Calibration Defaults Loaded Adjust travel limits, push autocalibration PB

3 3 Green Flashes Reverse Acting Mode

If you would like your servo to not operate in reverse

acting mode, set DIP switch 7 accordingly

4 4 Green Flashes 2-10VDC Input Command Signal Selected

If you require a different conguration, set DIP

switches 1, 2, and 3 accordingly

5 1 Red Flashes Handwheel engaged Push the Handwheel in towards the actuator

6 2 Red Flashes Command Signal Failure

Set DIP switches accordingly, send servo ap-

propriate signal

7 3 Red Flashes Feedback Pot Fault

Position the feedback Pot correctly, see Feedback

Pot calibration

8 4 Red Flashes Limit Switch Fault

Check wiring of limit switches, ensure that both

switches are not tripped simultaneously

9 5 Red Flashes Torque Switch Fault

Ensure that DIP switch 10 is positioned correct,

check wiring of torque switches, reverse direction

of actuator, correct over torque condition

10 6 Red Flashes Feedback Pot Wired In Reverse Correctly wire the Feedback Pot

Note: A ashing green LED provides status and warning information. The servo will operate normally in this state. Some ash

codes indicate a warning, where the servo has recovered automatically such as the detection of an invalid calibration. In this case,

a default calibration is automatically loaded that will allow the Servo to operate, but may not be a perfect match to the actuator.

The servo should be re-calibrated as soon as possible.

Loading...

Loading...