BRAY Series 70 Electric Actuator

Operation and Maintenance Manual

17

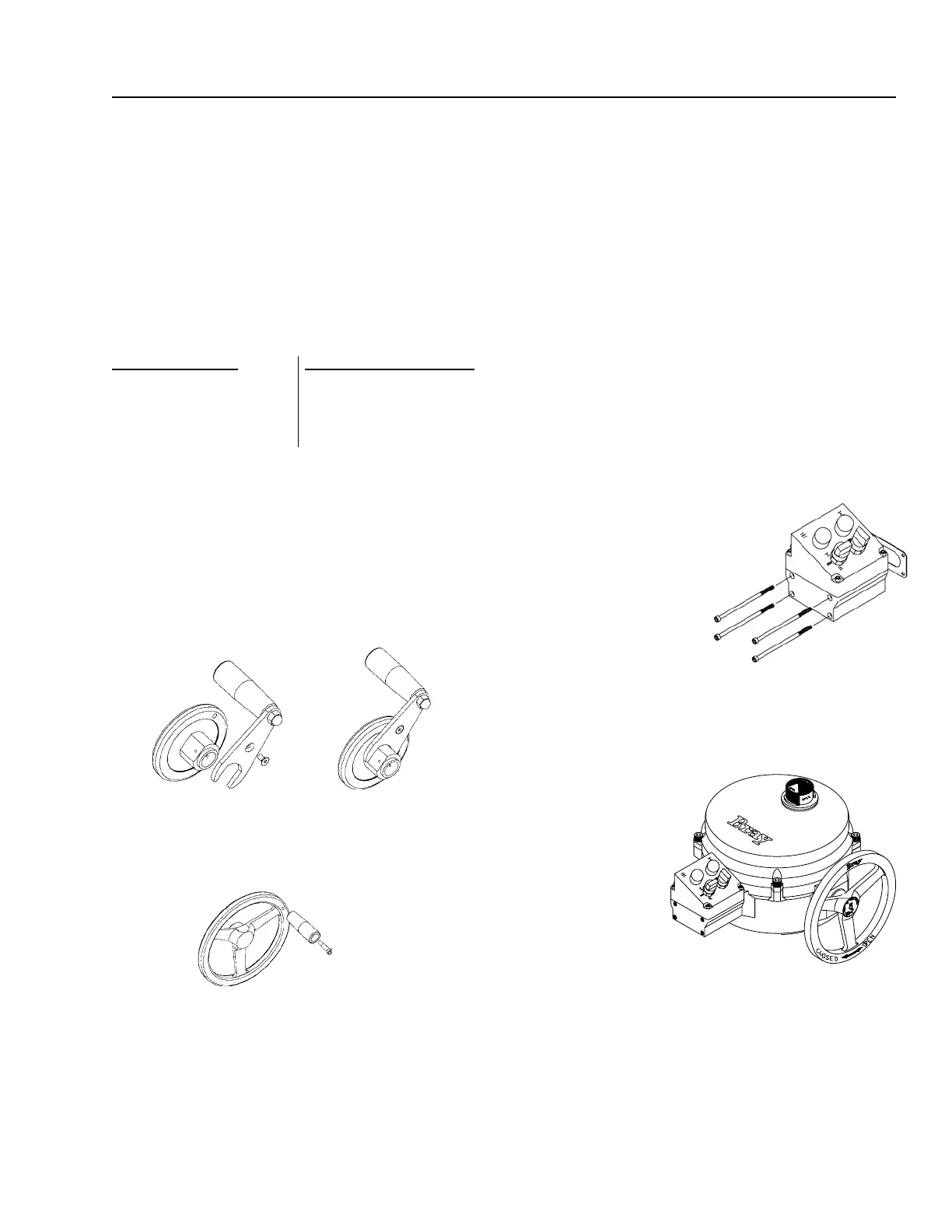

SPinner

A spinner is available to ease and speed the manual override

of the Bray Series 70 actuator. The Housing Size 6 units

mount the spinner on a lever which screws onto the back of

the handwheel. The Housing Size 12-180 units mount the

spinner on the rim of the handwheel. Note that care should

be exercised in the use of spinner equipped handwheels.

Rapid operation of the handwheel to close the valve may

cause water hammer. Also, rapid travel into a travel stop

may cause damage.

SPinner Kit cOnSiStS Of:

For Housing Size 6 For Housing Sizes 12-180

Spinner and lever assembly Socket head shoulder bolt,

Flat head socket cap screw, 1/4-20UNC x .75

#10-32UNF x 3/8 Spinner handle

tOOlS required:

• For socket head shoulder bolt and at head capscrew

• Hex key,

1

/

8

” for Housing Size 6

• Hex key,

3

/

16

” for Housing Sizes 12-180

inStallatiOn PrOcedure:

• For Housing Size 6 units simply position the lever onto

the back of the handwheel then screw the at head cap

screw in to place from behind.

• For Housing Size 12-180 units, put the socket head

shoulder bolt through the spinner handle and screw it

rmly into the handwheel rim.

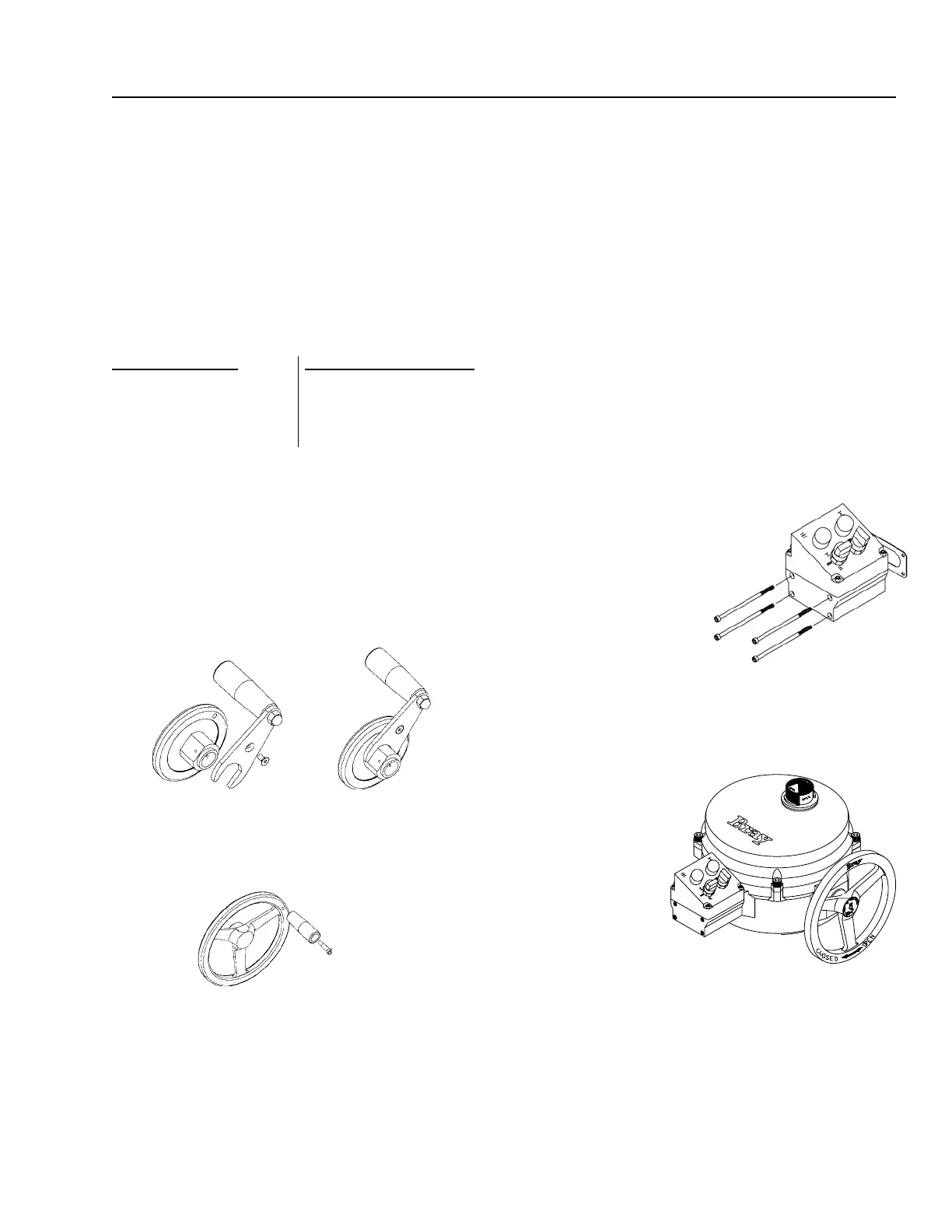

lOcal cOntrOl StatiOn (Single PhaSe POW-

ered actuatOrS)

Bray’s local control station gives the user the ability to locally

override the actuator electrically. The station is open / stop /

close operation in the local control mode. Red and green end

of travel indication lights are also provided. Depending on

how it is wired the control station

can be used on the on - off

units and the servo controlled modulating units. Optional

key operated locking switches are available.

Note: The control station used with On - Off S70 and that

used with modulating S70 have different contact blocks

internally, the correct part number must be used to ensure

you order the correct unit (see price sheet).

lOcal cOntrOl StatiOn Kit cOnSiStS Of:

1. Local control station assembly

2. Four socket head cap screws, #10-24UNC x 4.50 long,

for mounting the station to the actuator

3. A gasket for sealing the station to the actuator

4. Wiring diagram

tOOlS required:

• For tapping control station mounting holes on actuator,

#10-24UNC Tap.

• For wiring Screwdriver,

3

/

16

” at blade.

• For mounting and cover screws Hex key,

5

/

32

”

inStallatiOn PrOcedure:

1. Tap #10-24UNC holes

using the cored holes on

the side of actuator.

2. Adhere the gasket to the

control box.

3. Mount the control box

to the actuator using

the 4 long socket head

capscrews.

4. Wire the control box to the actuator in accordance to

the wiring diagram provided. The local control station

contains no terminal strips, and all wiring is direct to the

switches and lights via 2” x

3

/

4

” NPT holes in bottom of

housing.

Ordering the control station with optional pin con-

nector receptacles

will eliminate the

necessity of eld

wiring. The units

will be completely

factory wired and

tested.

Note: The inclined

cover of the local

control station can be

mounted in any of its

four symmetrical posi-

tions. If eld wiring is required , rst mount the base to the

actuator, then remove the cover to gain access for wiring.

*Local Control Station requires a dedicated set of auxiliary

switches for control station use only. Two additional adjust-

able auxilary switches are needed for remote indication of

open/close position in ONOFF congurations

Loading...

Loading...