8

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

Series 92-93 Pneumatic Actuator

Operations and Maintenance Instructions

WARNING

Some actuators may have spring cartridges installed.

Before disassembly, all spring cartridges must be

placed into the relaxed (fully extended) position. All

compressed air must be removed from inside the actuator

(See warning on previous page) and the actuator pinion

must be allowed to rotate so the springs may be relaxed.

Care must be taken to verify that any device connected

to the actuator, such as a valve mounted underneath,

is not preventing the movement of the springs to the

relaxed position.

If the actuator is installed on a valve, remove the actuator

from the valve, and move the actuator to a clean work

area. Remove the indicator pointer. Remove both end

caps by loosening the hex head end cap bolts. Remove

both pistons by rotating the pinion counter-clockwise

until the piston heads are protruding from the body.

Pull the pistons out. Using snap-ring pliers, remove the

pinion retaining ring and acetal washer, then remove

the pinion from the body. The pinion bearings, o-rings,

cam and spacer may then be removed.

Adding Spring Cartridges

WARNING

Before disassembly of the actuator, the pneumatic

air supply must be completely disconnected from

the actuator, and all compressed air stored within the

actuator must be released. Auxiliary devices connected

to the actuator, such as tubing, ball valves, solenoid

air valves, valve positioners, etc. can block the release

of air from within the actuator. Do not rely upon the

features or controls of any auxiliary device to release

the air from inside the actuator to render it safe for

disassembly.

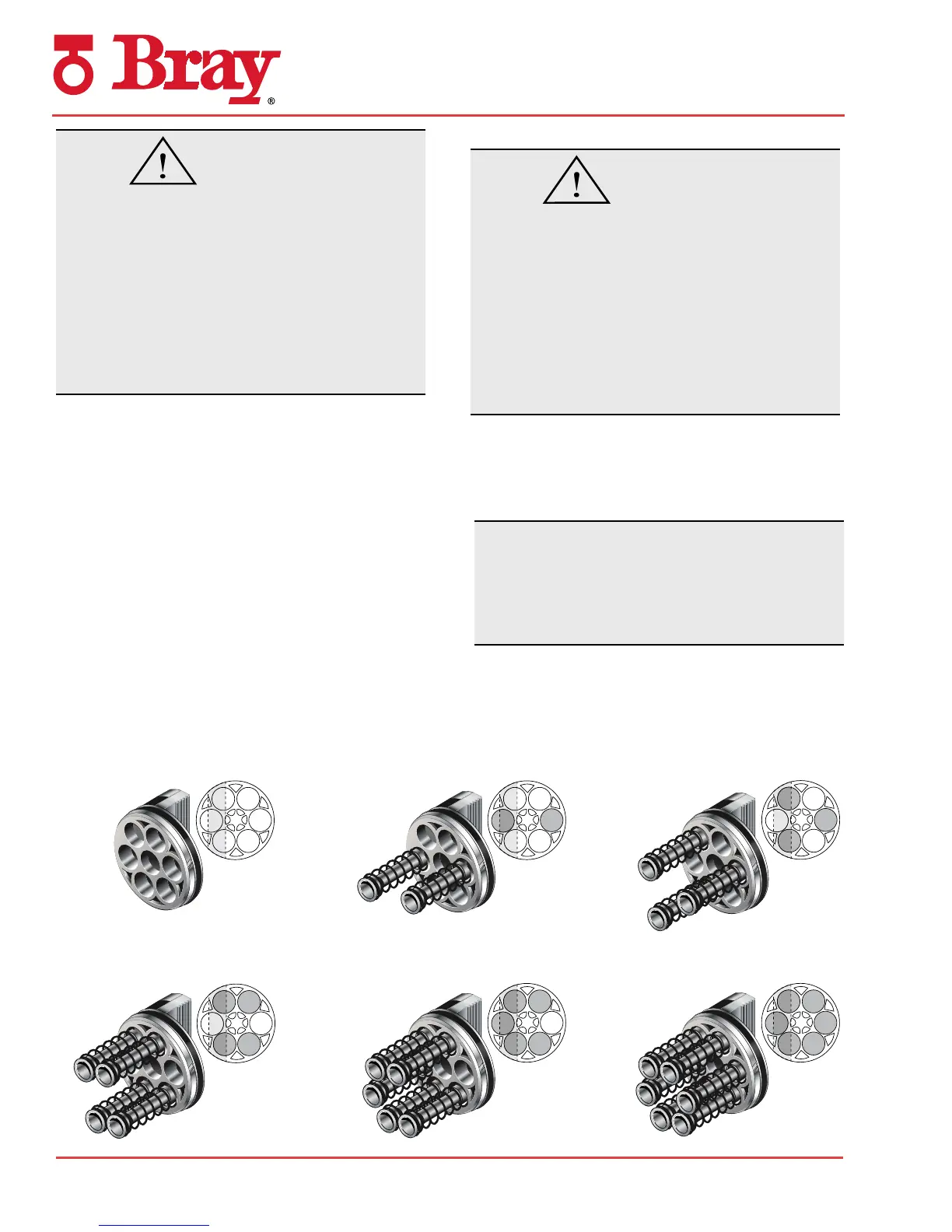

Move the pinion to the fully closed (0°) position. Remove

the end caps and insert the desired number of spring

cartridges into the end cap pockets, up to a maximum

of six cartridges per end cap.

NOTICE

For proper operation, actuators equipped with Spring

Cartridges should have the spring cartridges installed

in accordance with the positions shown in gure 2.

Align the end cap with the body so the spring cartridges

t into the piston pockets. Attach the end caps to the

body with the hex head end cap bolts. Tighten the bolts

gradually in a diagonal sequence.

Proceed to Final Assembly and Testing.

XX = SIZE CODE

2 SPRINGS

EACH PISTON

3 SPRINGS

EACH PISTON

4 SPRINGS

EACH PISTON

5 SPRINGS

EACH PISTON

6 SPRINGS

EACH PISTON

XX

XX

XX

Figure 2

Loading...

Loading...