4

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

Series 92-93 Pneumatic Actuator

Operations and Maintenance Instructions

Fail Closed Assemblies

If the actuator is attached to a valve, the buttery valve

is shipped in the full closed position (as no air pressure

is present to compress the springs and open the disc).

CAUTION

Installing the valve with the disc in the full closed

position may create a compression set on the seat

causing higher than expected torques or premature

seat failure. It is recommended to:

• Remove the actuator. Be sure to scribe the valve

and actuator to ensure the re-installed actuator is

in the exact same quadrant as originally cong-

ured

• Install the valve per the attached installation tag

instructions

• Re-install the actuator ensuring it is in the

proper quadrant

Mounting the Actuator to the Valve

The actuator is attached to the valve by means of the

studs and nuts furnished in the mounting kit. Thread

the studs into the proper holes in the actuator, before

installing the actuator on the valve. The studs should be

snug in the bottom of the tapped holes; there is no need

to torque them. Install the actuator on the valve making

sure that the base of the actuator ts at against the valve

mounting ange. Use the nuts and washers from the kit

to complete the installation. Torque the nuts in a diagonal

pattern to assure equal loading of the studs.

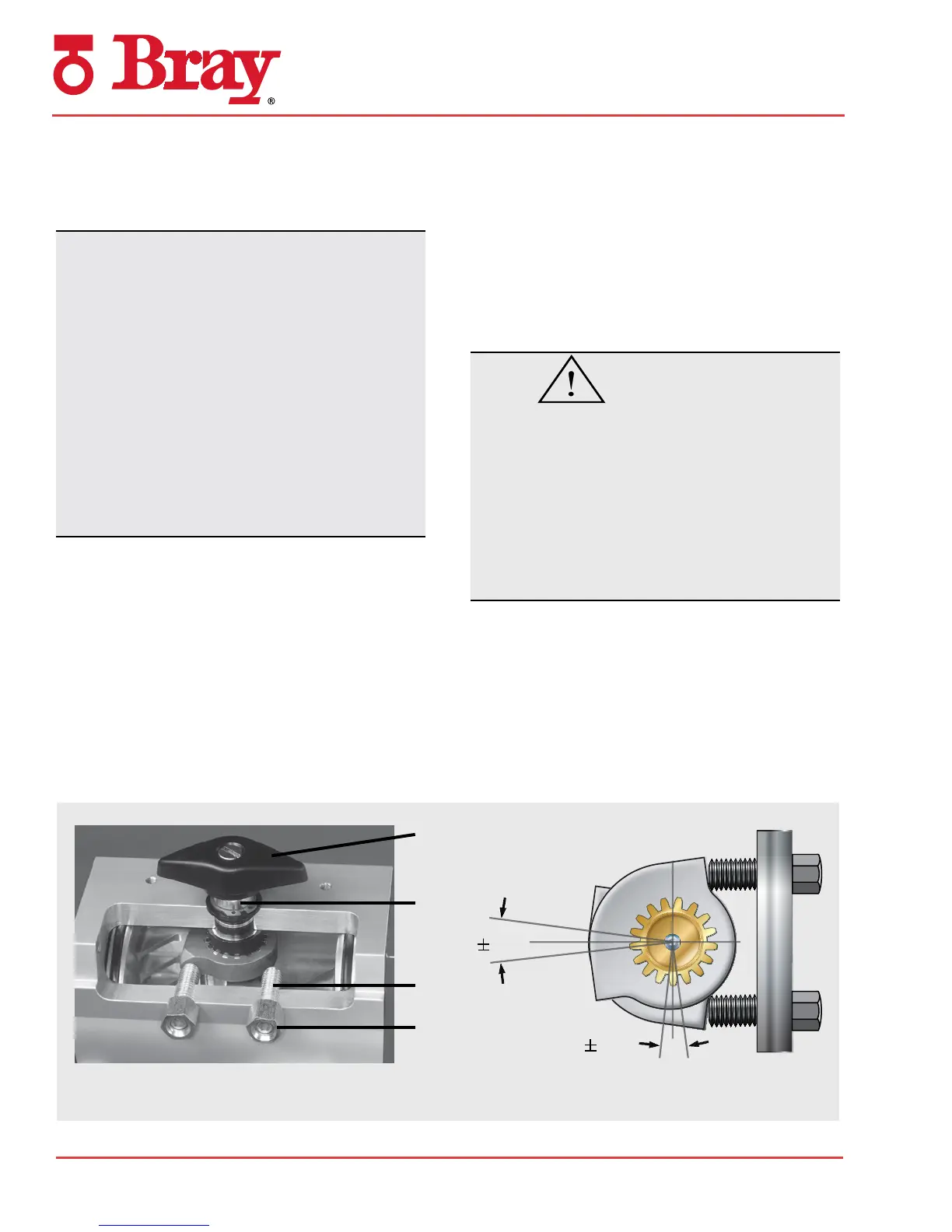

Setting the Travel Stops

The nal step in the installation process is to check the

travel stop settings. The travel stops are set for 90° of

travel at the factory; however, each installation is differ-

ent so they should be checked before putting the valve

in service. The actuators are designed with a nominal 5°

over or under travel at each end of rotation. A screwdriver,

an open end or box end wrench and a hex wrench, of the

appropriate size, are the only tools required to make the

necessary adjustments. Refer to Figure 1 below.

WARNING

Before setting the travel stops, the pneumatic air supply

must be completely disconnected from the actuator,

and all compressed air stored within the actuator must

be released. Auxiliary devices connected to the actua-

tor, such as tubing, ball valves, solenoid air valves,

valve positioners, etc. can block the release of air from

within the actuator. Do not rely upon the features or

controls of any auxiliary device to release the air from

inside the actuator to render it safe for disassembly.

Remove the black Position Indicator Pointer (23) to expose

the wrench ats on the top of the Pinion (3).

Rotate the valve to the desired position by using a

wrench on the wrench ats on the top of the Pinion (3).

Loosen the Lock Nut (12) on the Travel Stop Screw (13).

It is not necessary to remove the nut completely. Using

the hex wrench, turn the screw in or out until the desired

5°

5°

Figure 1

23

3

13

12

Loading...

Loading...