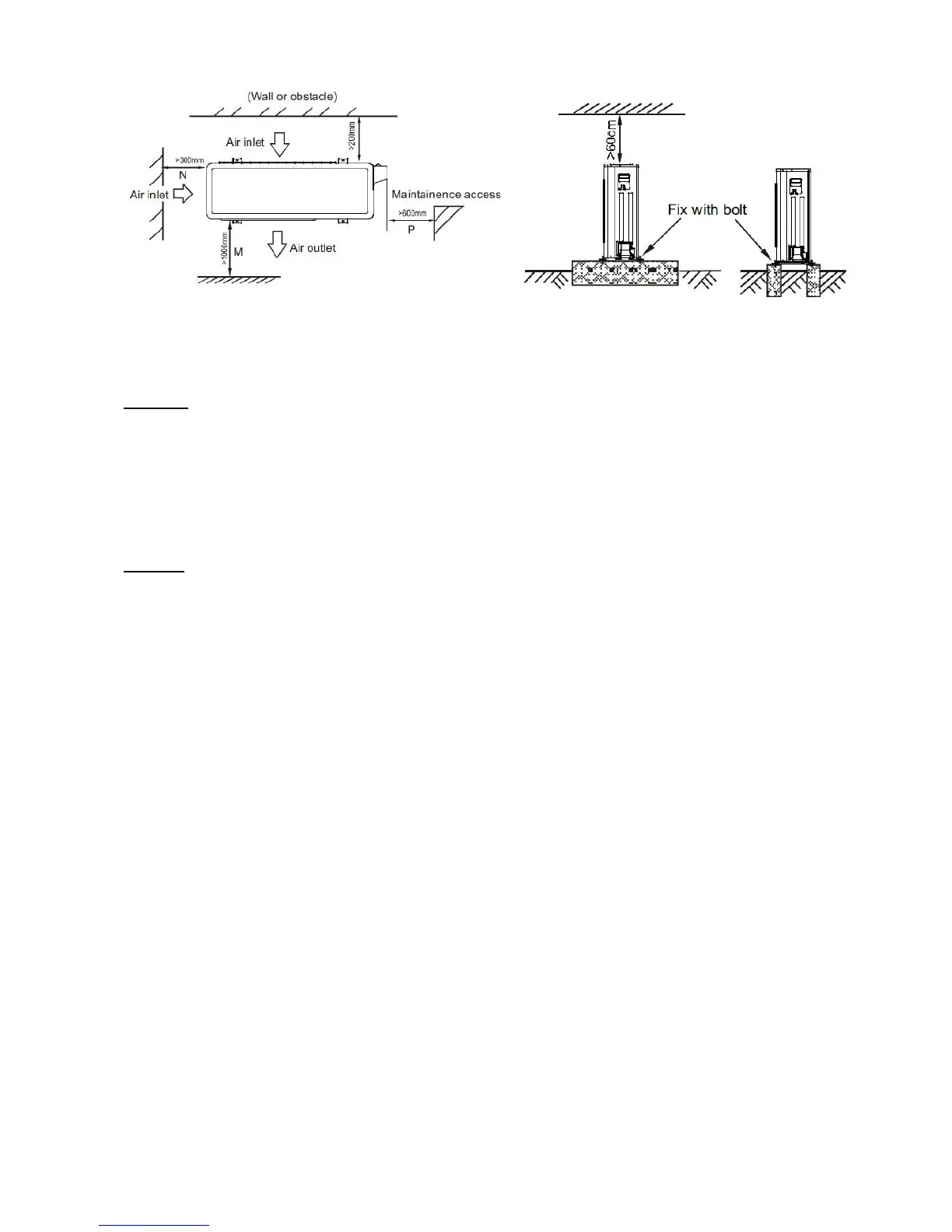

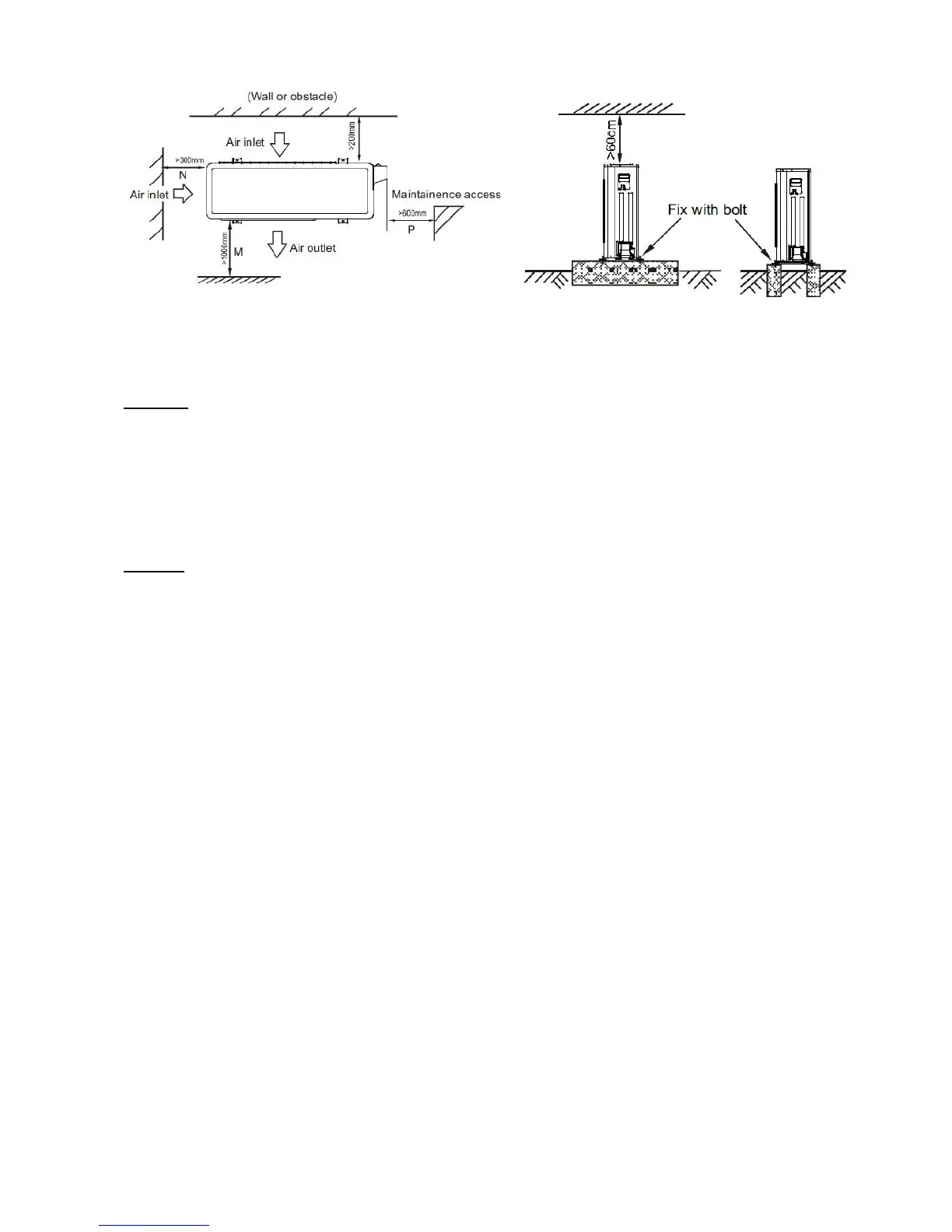

Fig. 16 – Outdoor Unit Clearances

6.0 REFRIGERATION CHARGE & PIPE-WORK

WARNING:

• Both indoor and outdoor units come delivered under positive pressure

• The Outdoor Unit is charged with sufficient R410a refrigerant for an interconnecting pipe run of 10m actual length

• The indoor unit is pressurised with 400kPa to 700kPa dry nitrogen

• Pipe end blanking plates must not be removed until the installer is sure the plates are not under positive pressure.

• A suction accumulator and oil separator has been fitted in the outdoor units

• Read all instructions and notes below before starting installation

• For flare connections please refer to section 6.2.

CAUTION:

• Use new, clean and sealed refrigeration grade pipe suitable for R410a

• Keep pipe ends sealed, both before and during installation, to avoid entry of moisture

• Suspend pipes with hangers or straps and seal openings around pipe penetrations with flexible material.

• Consider pipe expansion and leave space between pipes and adjacent structures

• Use brazing shields where required

• When brazing in the vicinity of valves likely to be affected by heat, they shall be lagged with a wet cloth

• All brazing operations must be completed with a small steady stream of nitrogen passing through the pipe-work to

limit scale build up and moisture contamination

• Never use the unit compressor as a vacuum pump

Loading...

Loading...