6.2 Pipe-work connection

Sweat connection:

• Locate the suction & liquid pipe service valves in the compressor compartment by removing the service access

panel

• Check that the service valves are tightly closed (Service Ball valves have been provided for suction and liquid

lines)

• Wrap each valve in turn with a wet cloth prior to sweating off its associated blanking plate (Flare nut connection is

fitted on some of the indoor units to avoid brazing)

• Braze the interconnecting liquid and suction pipes from the indoor unit

• Pressurise the indoor unit & pipe-work again with dry nitrogen and check for any brazed joint leaks. Repair as

necessary but ensure the system is not under pressure prior to brazing

• With the indoor unit pressure again released, evacuate to a vacuum pressure of 100 microns minimum

• Disconnect the vacuum pump whilst retaining the system vacuum

• Open the liquid line valve fully first, and then the suction line valve

Flare connection:

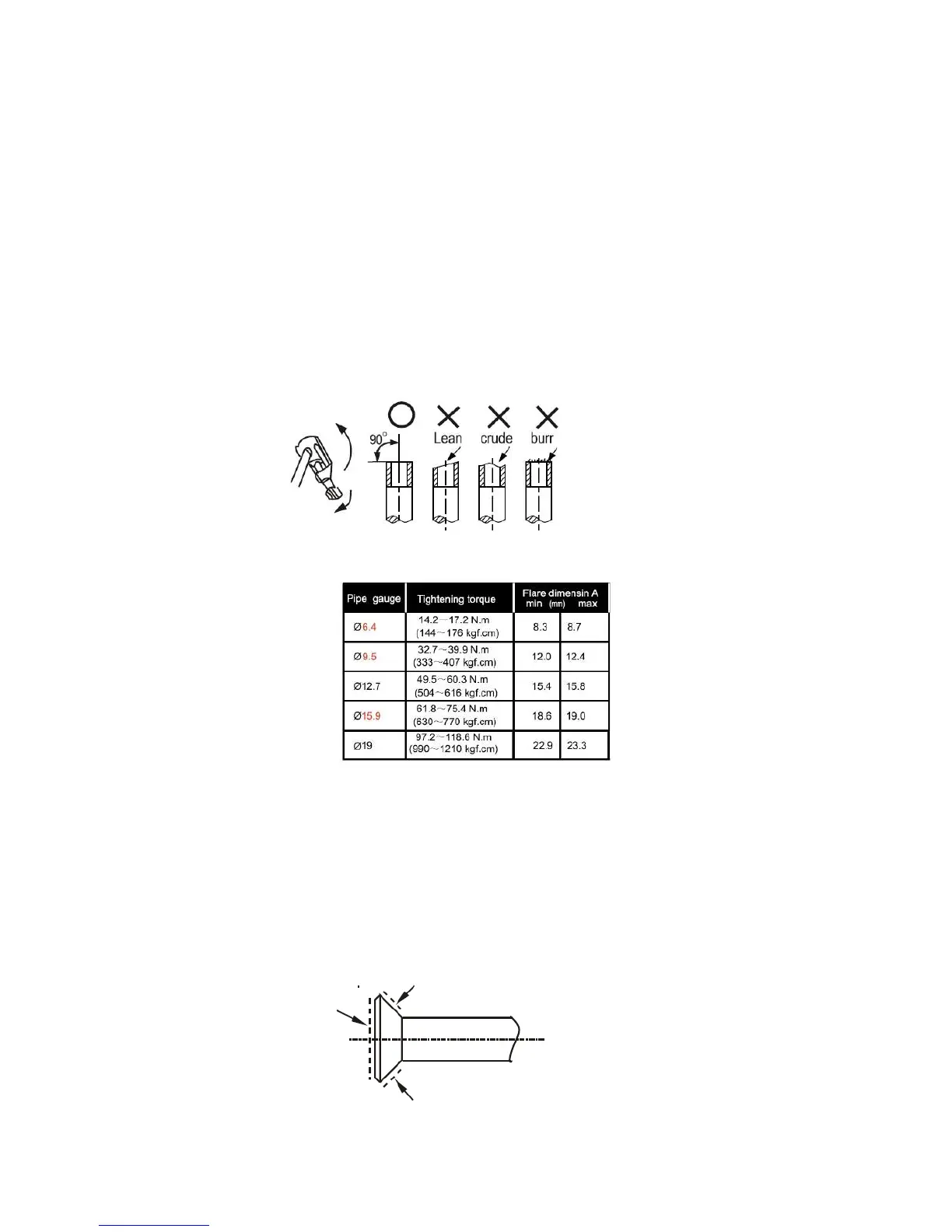

• Cut the pipe with pipe cutter

• Insert the flare nut into the pipe and flare the end

• Refer to the following table for the dimension of flare nut spaces:

Table 3 – Flare Dimensions and Flare Tightening Torque

• Connect the indoor unit first and then the outdoor unit.

• Bend the refrigerant pipe in the correct way to prevent damage.

• The bending angle should not exceed 90°.

• The preference is to place any b ends in the middle of the pipe. The larger the bending radius the better, as it reduces internal

pressure drop.

• Do not bend pipe more than is necessary.

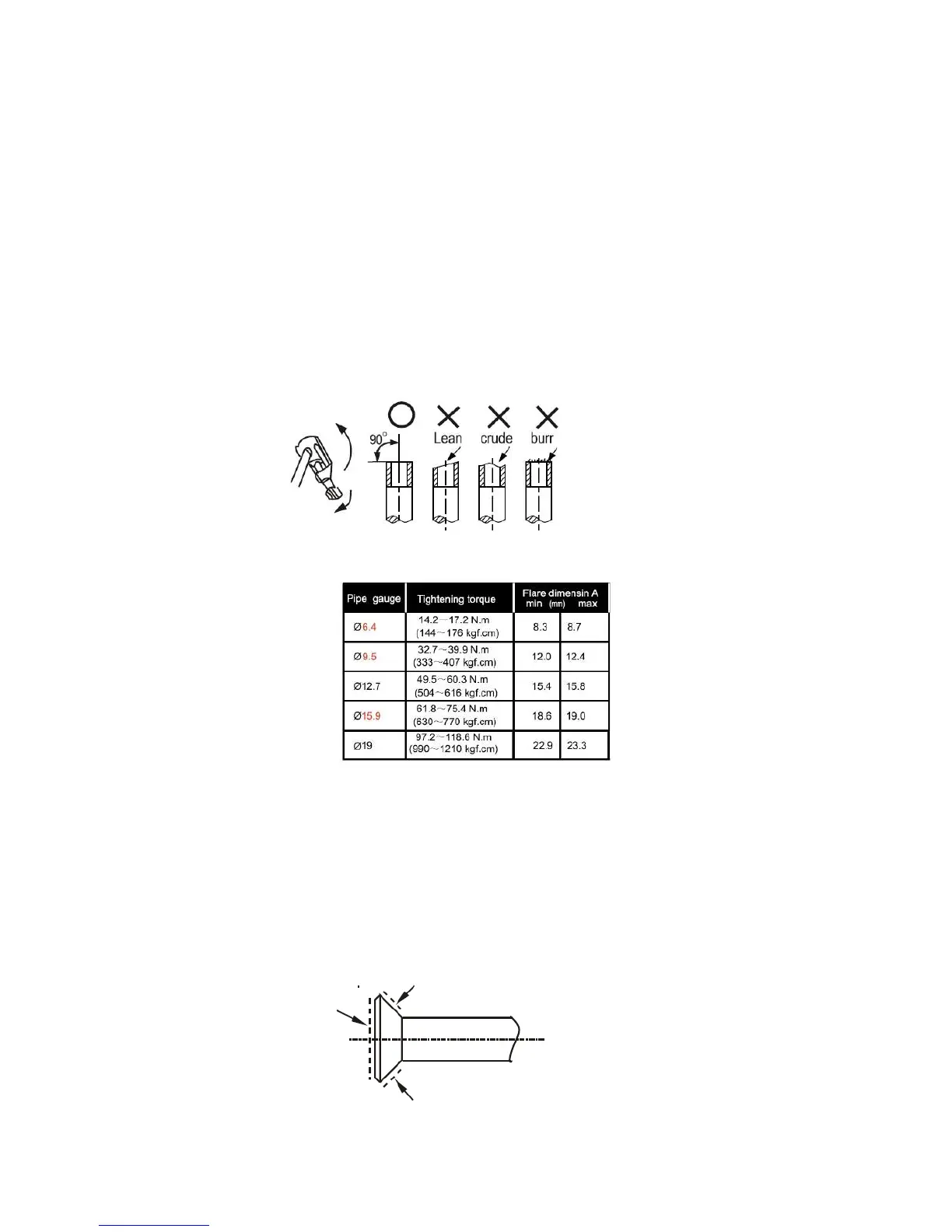

• When connecting the flare nut, coat the flare both inside and outside with approved oil and initially tight en by

hand 3 or 4 turns before tightening firmly.

Loading...

Loading...