Visual inspection is important to keep your printer up and running.

Verify all the moving parts of the machine and also check for leakage of ink.

After you have done the WTC, take the opportunity to clean the rubber Wiper Blades

to avoid the white ink to dry and stay on the Wiper. It will prevent dry particules of ink to

block the nozzles during the next cleaning.

Also clean all the caps of the maintenance station (specially the rectangle lip) to remove

again dry ink but also some u and lint of the T-shirts. They will allow the air to pass

through the capping station and reduce the good suction of the pump.

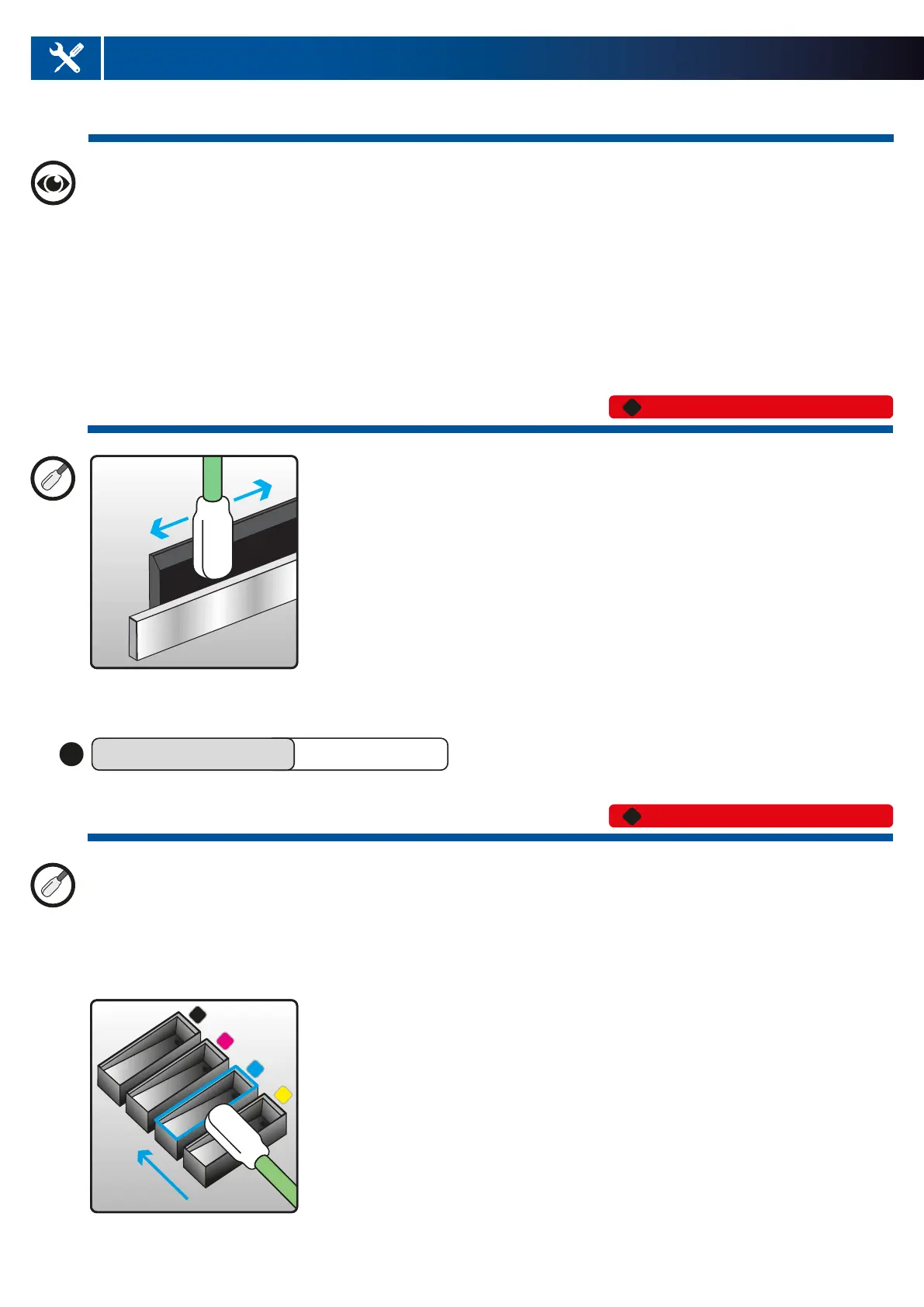

The wiper cleans the underside of the print heads to allow the

nozzles to re properly. The wiper is cleaned by passing across

the wiper cleaner.

Once this cleaner is dirty or over saturated, the wiper edge can

no longer be cleaned and therefore no longer clean the nozzle

plates.

Apply cleaning solution to a swab and wipe across the front

and backside of the 2 wiper rubber blades.

Check the wiper edge for any tear or separation from the metal base. If any exists, the

wiper sub-assembly must be replaced by a new one.

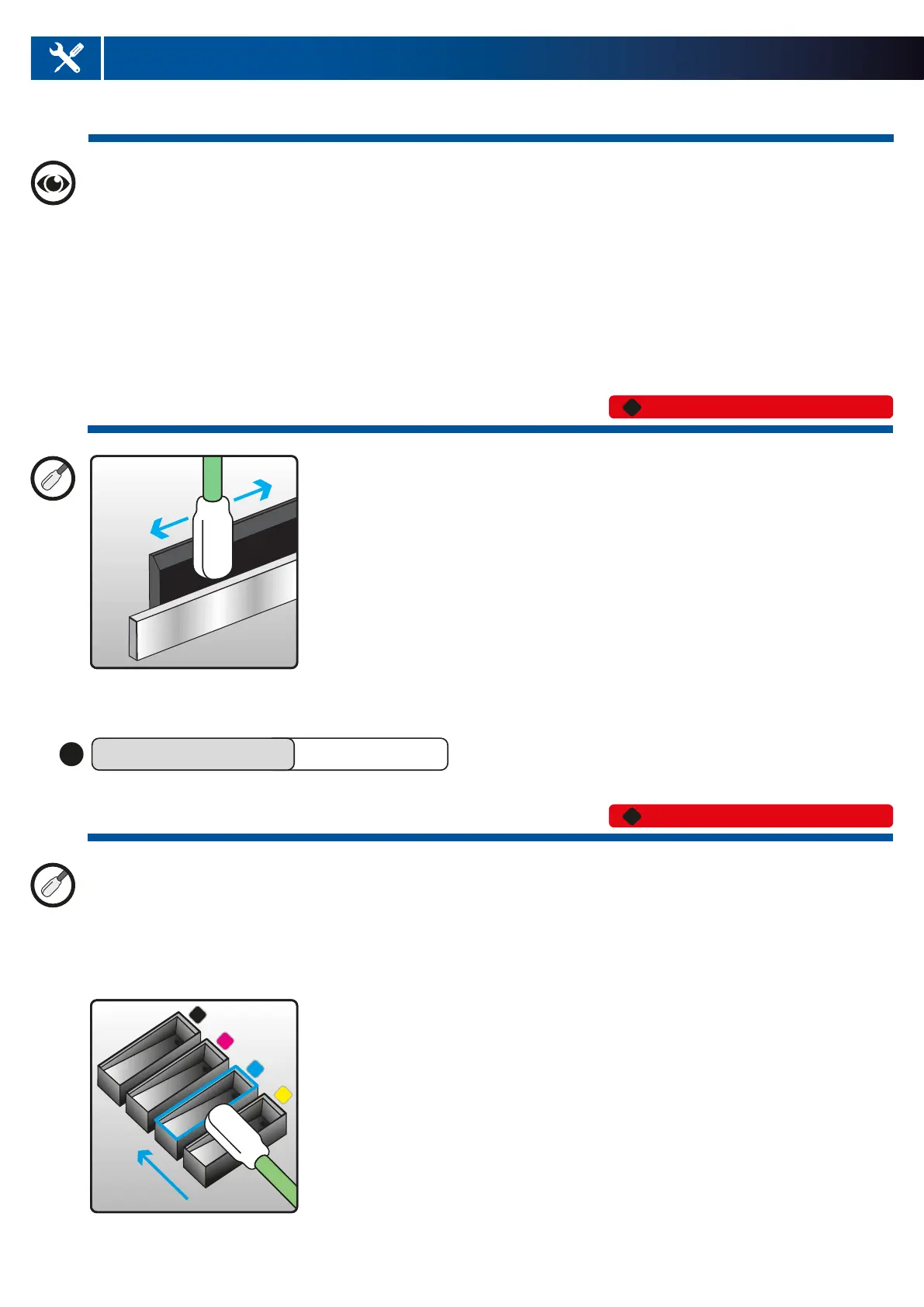

Once the wipers are clean, the rubbers caps must be cleaned with the swabs as well.

The rims of the cap rubbers press against the bottom of the print head’s CLP, to form a

seal so air cannot dry the heads. If the rims of the caps have debris, dried or excessive

ink, the ink will back away from the membrane and nozzles will misre.

If this continues over time, the print head will dry and eventually become defective.

Power on the printer. The printer will boot up as normal except it will drain each cap,

one at a time, before it moves the carriage.

Moisten a swab as done for the wiper blade cleaning, and

swab the edges and the inside of the rubber caps.

Use one side of a swab per cap so you do not contaminate

one color to another, from Y to C to M to K.

Clean White caps also !

Once all of the caps have been cleaned, insert the new wiper

cleaners in place. The wiper blades should be in the center,

between the two sets of 4 rubber caps.

> WEEKLY ADDITIONAL MAINTENANCE PROCEDURE

> RUBBER CAPS CLEANING :

> WIPER BLADES CLEANING :

ADDITIONAL WEEKLY MAINTENANCE

+

SPARE PARTS NUMBER:

SB3635001

4

!

TO BE DONE EVERY WEEK

!

TO BE DONE EVERY WEEK

Loading...

Loading...