100

ENGINE MANAGEMENT MODULE (EMM)

SENSORS AND FUNCTIONS

Throttle Position Sensor

The throttle position sensor is a rotary potentiome-

ter connected to the throttle plate shaft. The sen-

sor receives a voltage signal from the EMM. As

the throttle lever is rotated, the EMM receives a

return voltage signal through a second wire. This

signal increases as the TPS lever is advanced. A

third wire provides a ground circuit back to the

EMM.

Refer to TPS CALIBRATION on p. 159.

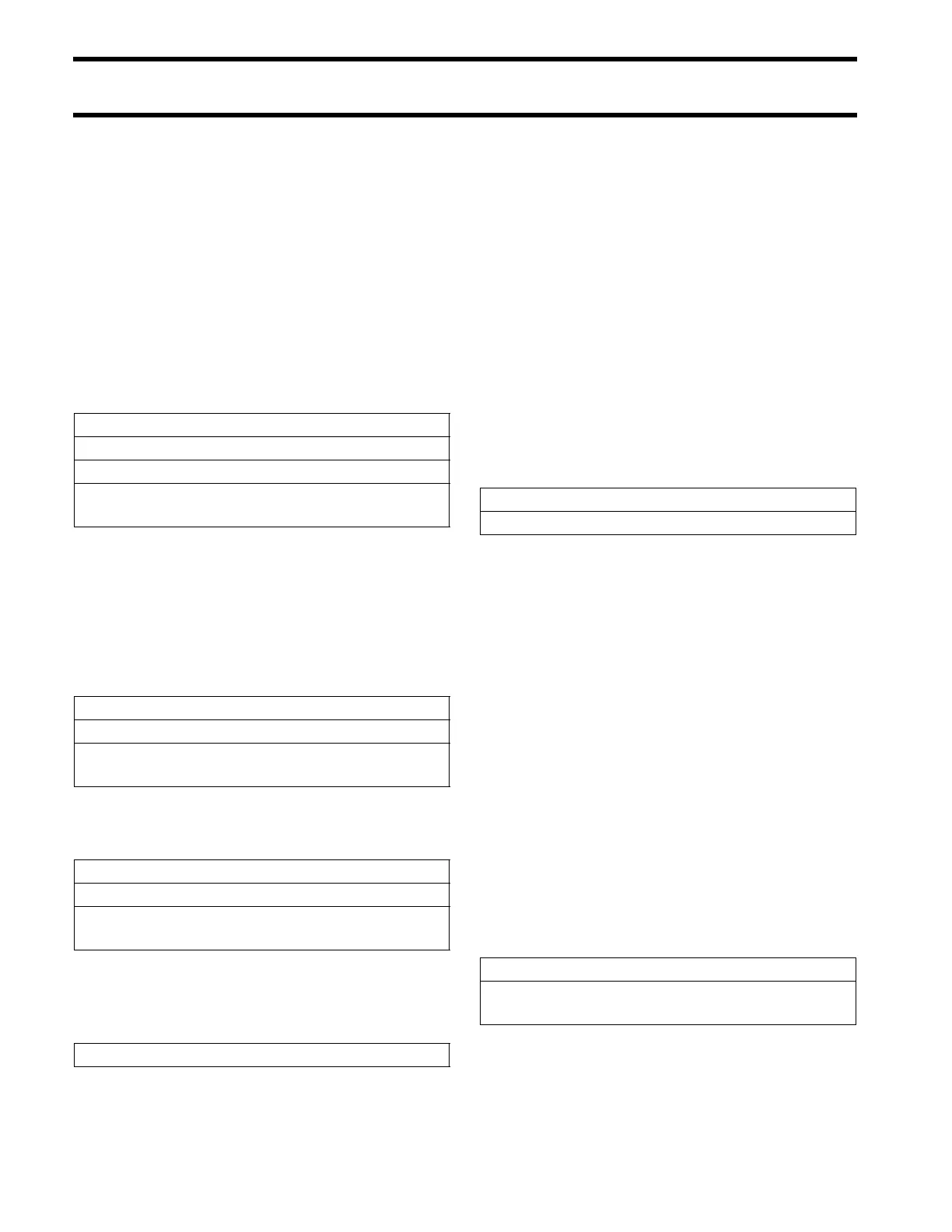

If the TPS sensor or circuit fails (below 0.15 volts

or above 4.95 volts), the EMM:

IMPORTANT: Once a TPS circuit fault has

been detected, the outboard will not accelerate

above idle speed. To reset, stop the outboard and

correct the fault.

If the TPS sensor circuit indicates below 0.2 volts,

the EMM:

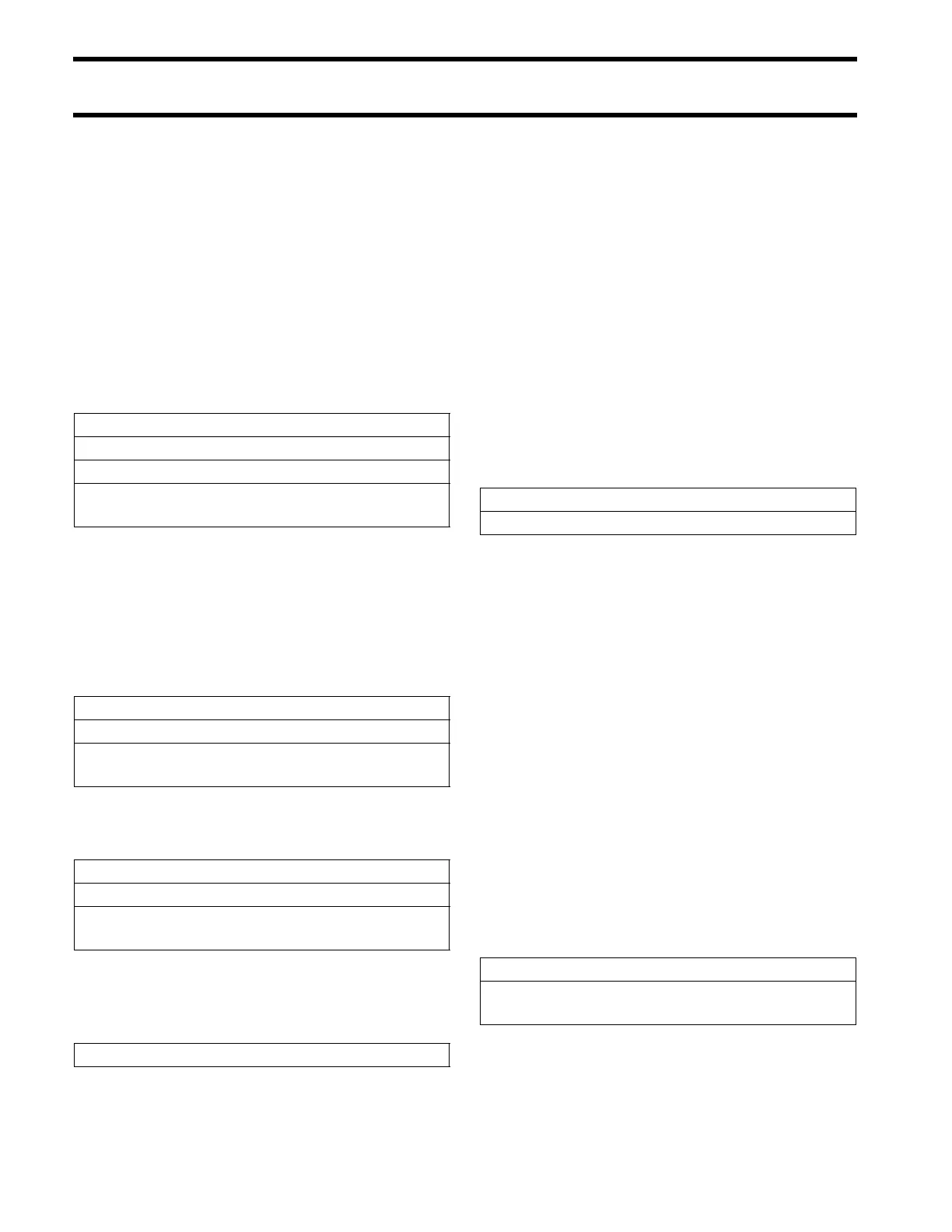

If the TPS sensor circuit indicates above 4.85

volts, the EMM:

If the TPS sensor circuit indicates above 0.65

volts when the key is turned to the ON position,

the EMM:

If the outboard is started, the code is stored.

If code 11 is present as both a Hard Fault and a

Stored Fault, refer to Control Cable Installation

on p. 60.

Crankshaft Position Sensor

The CPS is a magnetic device. It is mounted on

the reed plate, adjacent to the flywheel.

Encoder rib spacing on the flywheel coincides with

crankshaft position. As the encoder ribs of the fly-

wheel pass the magnetic field of the CPS, an AC

voltage signal is generated. The EMM uses this

signal to identify crankshaft position and speed,

generate a tachometer signal, and control fuel and

ignition timing.

If the sensor is damaged or the signal is intermit-

tent (10 instances), the EMM:

Approximate air gap between CPS and flywheel

encoder ribs is .073 (1.85 mm).

Use the engine Monitor screen of the Evinrude

Diagnostics Software program to check CPS

operation. The outboard should indicate an RPM

reading while cranking. If the CPS or its circuit

fails, no RPM reading will be generated and the

outboard cannot run.

Neutral Switch (V4 Models)

The powerhead mounted neutral switch provides

a ground signal for the EMM to indicate shift link-

age position when a tiller kit has been installed.

This allows the EMM to provide start in gear pro-

tection. Fuel and ignition functions are turned off

on tiller models if the neutral switch is not acti-

vated.

If the switch is not functioning properly, the EMM:

The engine Monitor screen of the diagnostic pro-

gram displays switch position, NEUTRAL or IN

GEAR. Make sure switch is operating properly.

Stores a service code 12

Limits engine RPM to IDLE

Initiates EMM SENSOR FAULT (LED 3)

Initiates the SystemCheck

CHECK ENGINE light

Stores a service code 13

Initiates EMM SENSOR FAULT (LED 3)

Initiates the SystemCheck

CHECK ENGINE light

Stores a service code 14

Initiates EMM SENSOR FAULT (LED 3)

Initiates the SystemCheck

CHECK ENGINE light

Initiates a service code 11

Stores a service code 16

Initiates EMM SENSOR FAULT (LED 3)

Stores a service code 19 (tiller models only)

Initiates EMM SENSOR FAULT LED

(Starting Mode only)

Loading...

Loading...