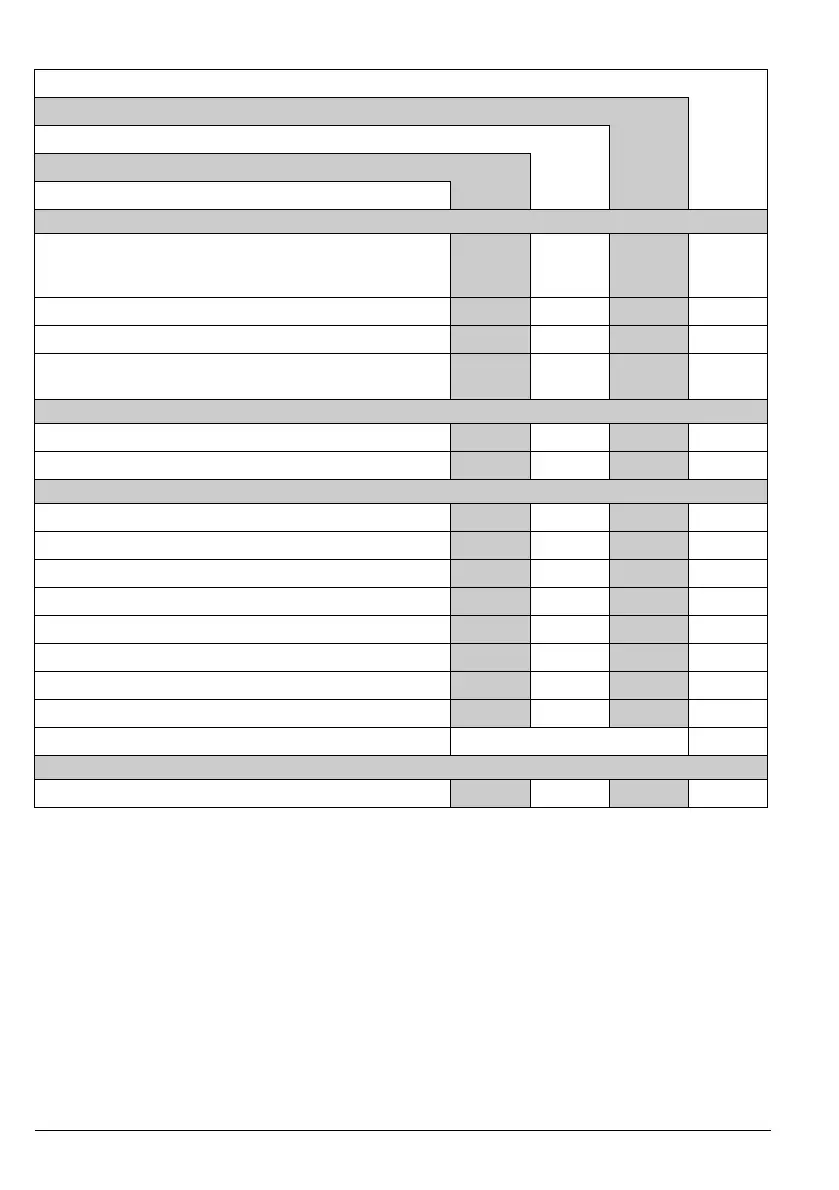

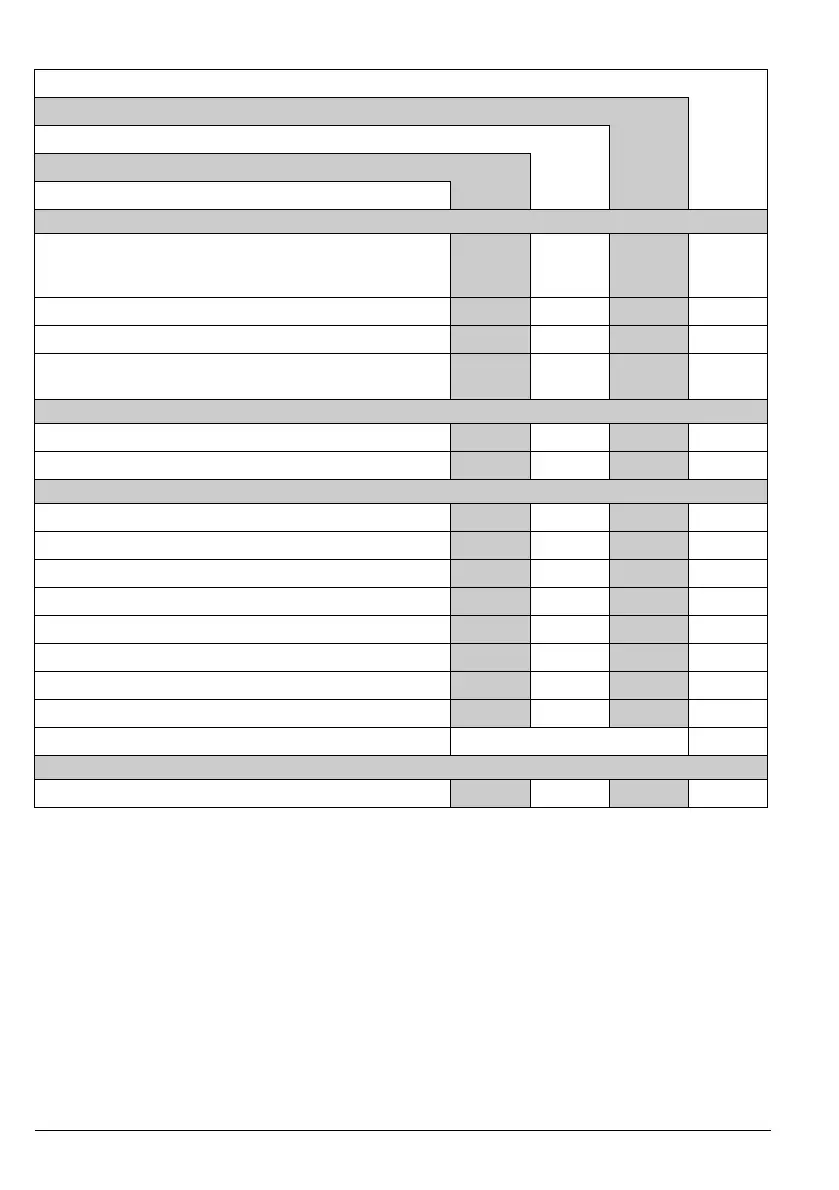

30

Inspections and Maintenance

A: ADJUST

C: CLEAN

I: INSPECT

L: LUBRICATE

R: REPLACE

RS: REPAIR SHOP

O: OPERATOR

(1) At storage period or after 100 hours of use

whichever comes first.

(2) Replace at 200 hours of use, irrespective of the

number of years.

(3) Spray an anti-corrosion lubricant on metallic

components in engine compartment.

(4) Every 10 hours in salt water.

(5) Daily flushing in salt water or foul water use.

(6) Replace if required.

(7) Lubricate for corrosion protection.

(8) Inspect each month (every two weeks in salt)

and change when necessary

TO BE PERFORMED BY

EVERY 200 HOURS OR 2 YEARS

EVERY 100 HOURS OR PRE-SEASON

FIRST 25 HOURS

PART / TASK

ELECTRICAL SYSTEM

Test the engine cut-off switch and the monitoring

beeper at first 50 hours and every 100 hours or

once a year

II

Spark plugs IIRRS

Ignition coils

II, L RS

Electrical connections and fastening (visual

inspection)

II RS

STEERING SYSTEM

Steering cable and connections I (4) I O

Steering nozzle bushings

I (4) I O, RS

PROPULSION SYSTEM

Carbon ring and rubber boot (drive shaft) II RS

Shifter system, cable and connections

I (4) I O, RS

Reverse gate L (4) L RS

Drive shaft / impeller splines

I, L RS

Drive shaft

L (7) RS

Impeller boot II RS

Impeller shaft seal, sleeve and O-ring

I R (2) RS

Impeller wear ring clearance

II RS

Sacrificial anode I (8) O

HULL AND BODY

Ride plate and water intake grate I O

Loading...

Loading...