16

GV

HI

M

GRN/YEL

C

NOTE #3

BRN

BLU

BRN

GRN/YEL

RED

RED

FRS

LS

NOTE #11

ORN

YEL

HSI

L1

NOTE #2

GND

NEUTRAL

FU2

FUSE OR CIRCUIT

BREAKER & DISCONNECT

SWITCH (WHEN REQ’D)

BLK

ILK

PL5

JB

1

2

SE

C-1

LE

D

SEC-2

FUSE 3-AMP

PLT

ACRDJ

0.5 AM

P

@ 24

VAC

HUM

TE

ST/T

WIN

ON

OFF

32

1

DL

Y

OFF

LH

T

W/

W1DHUM G

24V

om

C

W2 Y/Y2 R

Y1

TRAN

L1

PR-1

EAC-1

OL

SPARE - 1

BLWR

BHT/CLR

BHI/

LOR

COOL

LO-H

EAT

HI-HEAT

START

GRN/YEL

BLWM

NEUTRAL

- L2

EAC-2

RED

BLU

ORN

YEL

BLK

LO

MED LO

MED

HI

MED HI

RED

BLU

WH

T

WH

T

BRN

BRN

BL

K

WHT

BLK

WH

T

IHI/LOR

HSIR

ID

R

LO

HI

HS

I

GRY

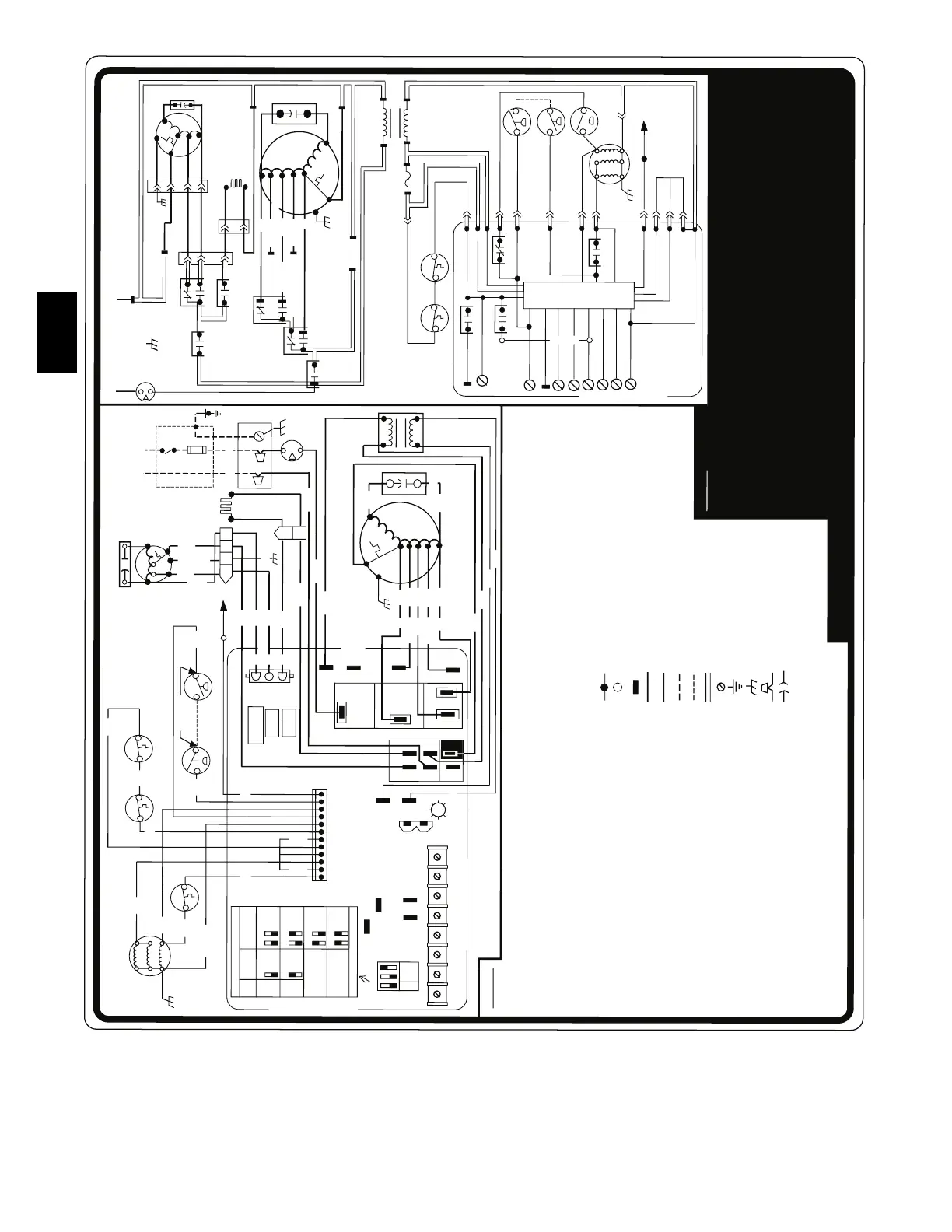

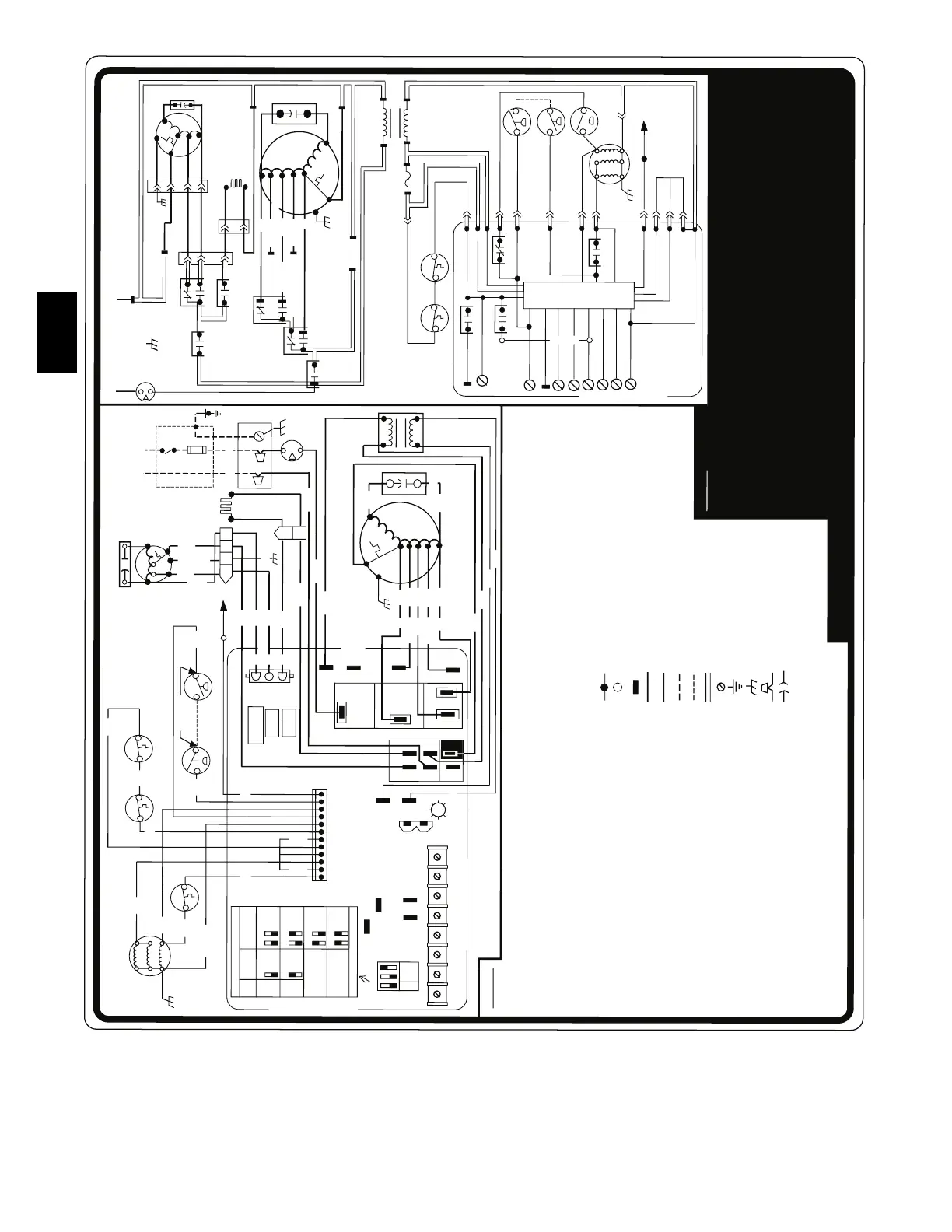

CONNECTION DIAGRAM

BLK

1

HSI

2

IDM

1

2

3

HI

COM

LO

SCHEMATIC DIAGRAM

(NATURAL GAS & PROPANE)

IDR

TO 115VAC FIELD-DISCONNECT SWITCH

ILK

EQUIPMENT

GROUND

1

2

3

HSIR

IHI/LOR

PL2

L2

L2

CAP-1

OL

ST

ART

BLWM

COM

LO

MED LO

MED

HI

ME

D HI

LO HEAT

SPARE-2

COOL

ING

SP

ARE-

1

BHI/LOR

BHT/CLR

BL

WR

EA

C-2

EA

C-1

TR

AN

L2

L2

115VAC

24VAC

SEC

2

SEC 1

PR1

FU1

NOTE #6

PL1-8

GVR-2

HUM

R

ACR

PL1-12

HP

SR

GV

LPS

NOTE #11

LGPS

(WHEN USED)

HPS

HI

PL1-2

PL1-

4

P

L1-3

PL1-1

0

PL1-5

W/W1

CPU

GVR-1

TE

ST/TWIN

DHUM

W2

Y/Y2

G

Y1

C

OM 24V

NOTE #3

C

M

PL1-1

LPS

(WHEN USED)

LGPS

WHT

FS

E

PL1-9

PL1-1

1

P

L1-

7

LEGEND

ACR AIR CONDITIONING RELAY, SPST (N.O.)

ACRD

JAIR

CONDITIONING RE

LAY DISABL

E JUMPER

BHI/

LOR BLOWER MOTOR SPEED CH

ANGE RELAY, SPDT

BHT

/

CLR BLO

WER MOTOR SPEED CHANGE RELAY, SPDT

BLWR BLOWER MOTOR RELAY,

SPST-(N.

O.)

BLWM BL

OWER MOTO

R, PERMANENT-

SP

LIT-CA

PA

CI

TOR

CA

P 1, 2 CAPACITOR

CPU MICRO

PROCESSOR

AND CIRCUITRY

DHUM DHUM CONNE

CTION

EAC-1E

LECTRONIC AIR CLEANER CONNECTION (11

5 VA

C 1.0 AM

P MAX.)

EA

C-2 E

LECTRONIC

AIR CLEANER

CONNECTION (COMMON)

FRS FL

AME ROLLOUT SW.

-MANUAL RESET,

SP

ST-(N.C.)

FS

E FLAME-PROVING ELECTRODE

FU1 FUSE, 3 AMP, AUT

OMOTIVE BLADE TY

PE

, FACTORY INSTALLED

FU2 FUSE OR CIRCUIT BREAKE

R CURRENT IN

TE

RRUPT DEVICE

(F

IELD SUPPLIED AND INSTALLED)

GND EQUIPMENT GROUND

GV GAS

VA

LV E -

RE

DUNDANT

GV

R 1, 2 GAS VA

LV E R EL AY, D P

ST-(N.O.)

HPS HIGH-HEAT PR

ESSU

RE SWITCH

, S P

ST (N.O.)

HPSR HIGH-HEAT

PRESSU

RE SWIT

CH RELAY, SP

ST (N.C.)

HSI HOT SURFACE IGNITER (115

VA

C)

HSIR HOT

SU

RFACE IGNI

TER RELAY, SPST (N.O.)

HUM 24VAC

HUMIDIFIER CONNE

CTION

(0.5 AMP. MAX.)

IDM I

NDUCED DRAFT MO

T

OR, 2-SPEED,

SHADED

POLE

IDR INDU

CED

DRAFT MOTOR

RE

LAY,

SPST-(N.O.)

IHI/LOR INDU

CER MOTOR SP

EED CHANGE RELAY, SPDT

ILK BLOWER ACCESS PA

NE

L

INTERLO

CK SWITCH, SP

ST-(N.O.

)

JB JUNCTION BOX

LE

DL

IGHT-EMITTI

NG DIODE FOR ST

AT

US CODES - AMBER

LGPS

LO

W

GAS

PRESSURE SWITCH, SP

ST-(N.O.)

LP

S LOW-HEAT PRESSURE SWITCH, SPST (N.O.)

LS

LIMI

T SWITCH, AUTO-R

ESET,

SP

ST (N.C.)

OL AU

TO-RESET INTERNAL

MOT

OR

OV

ERLOAD TEMPERATURE SWITCH (N.C.)

PCB PRINTED CIRCUIT BOARD CONTROL

PL1 12-CIRCUIT PCB CONNECTOR

PL

23-C

IRCUIT PCB HSI & IDM CONNEC

TO

R

PL

36-C

IR

CU

IT IC

M MOTOR CONNEC

TOR

(NOT SHOWN)

PL

44-C

IR

CU

IT IDM

CONNECTOR

PL

52-C

IR

CU

IT HSI CONNECTOR

PL

T3

-CIRCUIT FACT

ORY TEST CONNECTOR

TRAN TRAN

SFORMER, 115VAC/24VAC

TEST/TW

IN COMPONENT TEST & TWINNING

TERMINAL

JU

NCTION

TER

MI

NAL

CO

NTROL

PCB TERMINAL

FA

CTORY

POWER WIRING (115VAC)

FACTORY CONTRO

L WI

RING (24V

AC

)

FIELD CO

NTROL

WIRING (115VA

C)

FIELD CO

NTROL

WIRING (24VAC)

CONDU

CTOR ON CONTROL PCB

FIELD WI

RI

NG SCREW TERMINAL

FIELD EART

H GROUND

EQUIPMENT GROUND

FIELD SPLICE

PLUG

RE

CEPTACLE

PCB

PL1-6

L1

NOTE

#10

L2

PL4

PL5

WHT

WHT

RED

BLK

PL2

IDM

NOTE #8

1 AMP

@ 115 VAC

S

TA

TUS CODE

FU1

NOTE #6

PL1

1

SELECT CHART

SW

LO-HT

ONLY

BLOWER

OFF-DELAY

ON

OFF

1

ON

LY

HEAT

LO

HEAT

NORM

23

90

SEC.

ON

OFF

1

2

3

120

SEC

.

ON

OFF

23

150

SEC.

ON

OFF

2

3

180

SE

C.

HPS

FAC T

ORY SETTINGS

BLW

HI

HEAT

NO

TE #5

*

*

*

SP

ARE-2

FSE

RED

ACRDJ

326797-101 REV. A

1. If any of the origin

al equipment

w

ire i

s

repl

aced use wi

re

rat

ed for 105°C.

2. Use only copper wire between the disconne

ct switch and t

he furnace j

unc

tion box (JB).

3. This wire must be connected to f

urnace sheet metal for contr

ol t

o

prove fl

ame.

4. Symbols are electrical represen

tation onl

y.

5.

Solid lines inside PCB are printed circuit board conductors and are not included in the legend.

6. Replace only with a 3 amp fuse.

7. Blower motor (BL

WM) and inducer motor (IDM) contain in

ter

nal auto-reset thermal o

ve

rload

swit

che

s (

OL

).

8. Neutral connections

a

re interchangeable w

it

hi

n th

e NEUTRAL

connect

or b

lock.

9. Blower motor speed select

i

ons are for average conditions, see inst

allati

on

instructions

for opt

imum s

election.

10. MED not available on

some mode

ls.

11. Factory connected

when

LG

PS is not used.

12. Ignition lockout will occur after

four consecutive unsu

ccessful trials-for-igniti

on

. Contr

ol will auto

-r

es

et

a

fter

three hours.

13.

Blow

er-on del

ay: gas hig

h-

heat

60 se

conds, gas low-heat 45 seconds, cooling or heat pump 2 sec

onds.

14. Blower

of

f-delay: gas heating selections are 90, 120, 150,

180 seconds, cooling or

heat pump 90 seconds o

r

5 seconds when dehumidify call is active.

NOTES:

PR

INTED CI

RCIUT BOARD

PRINTED CIRCIUT BOARD

FRS

LS

WHT

WHT

PL3

IDM

123

BL

K

4

GR

N/YEL

CAP-2

BRN

BRN

GRN

RED

WH

T

OL

/YEL

CA

P-1

NOTE #2

OL

4

CAP-2

NO

TE #9

A02176

Fig. 22 -- Wiring Diagram

352AAV

Loading...

Loading...