5

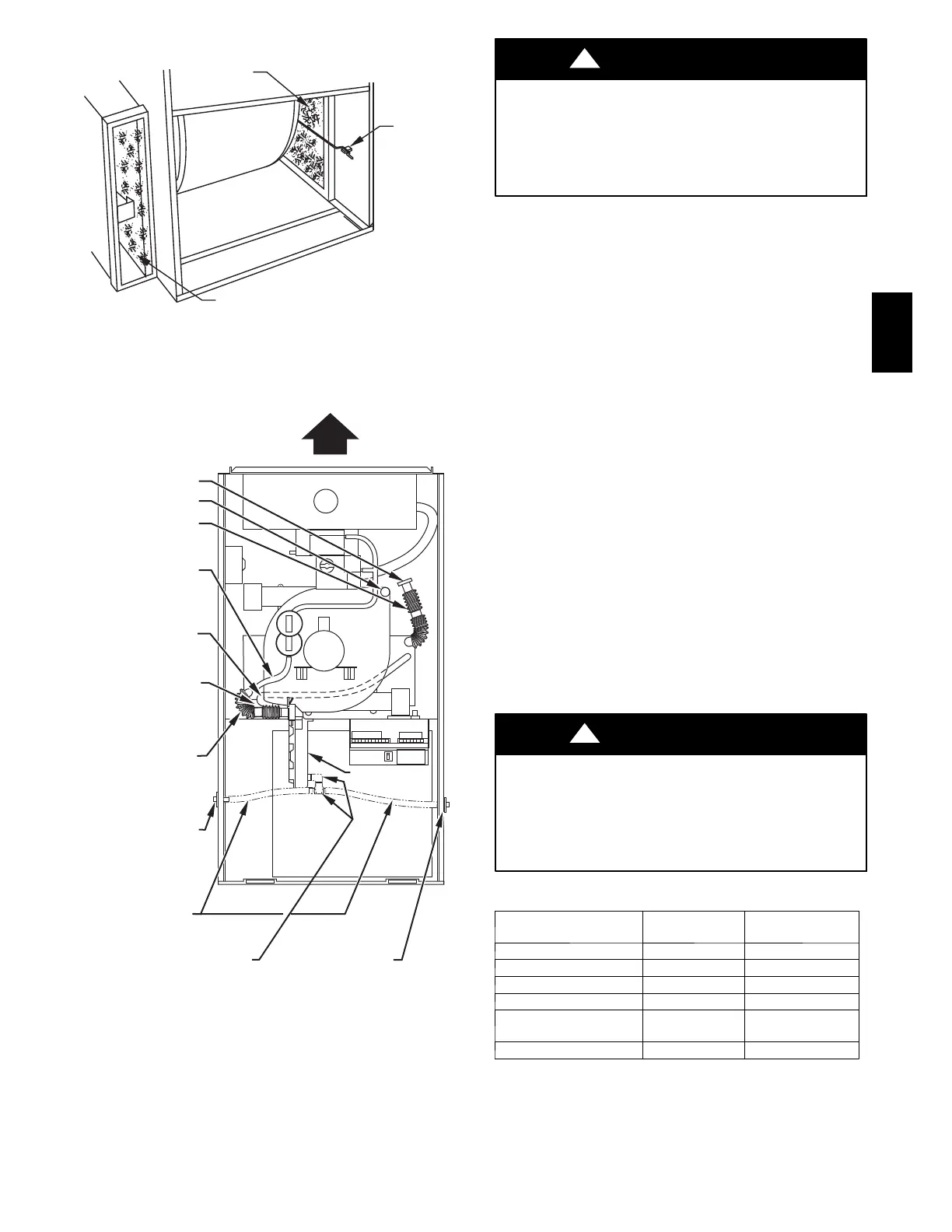

FILTER

RETAINER

FILTER

IN FURNACE

WASHABLE FILTER OR

DISPOSABLE MEDIA

FILTER IN FILTER CABINET

A08589

Fig. 4 -- Filter Installed for Side Inlet

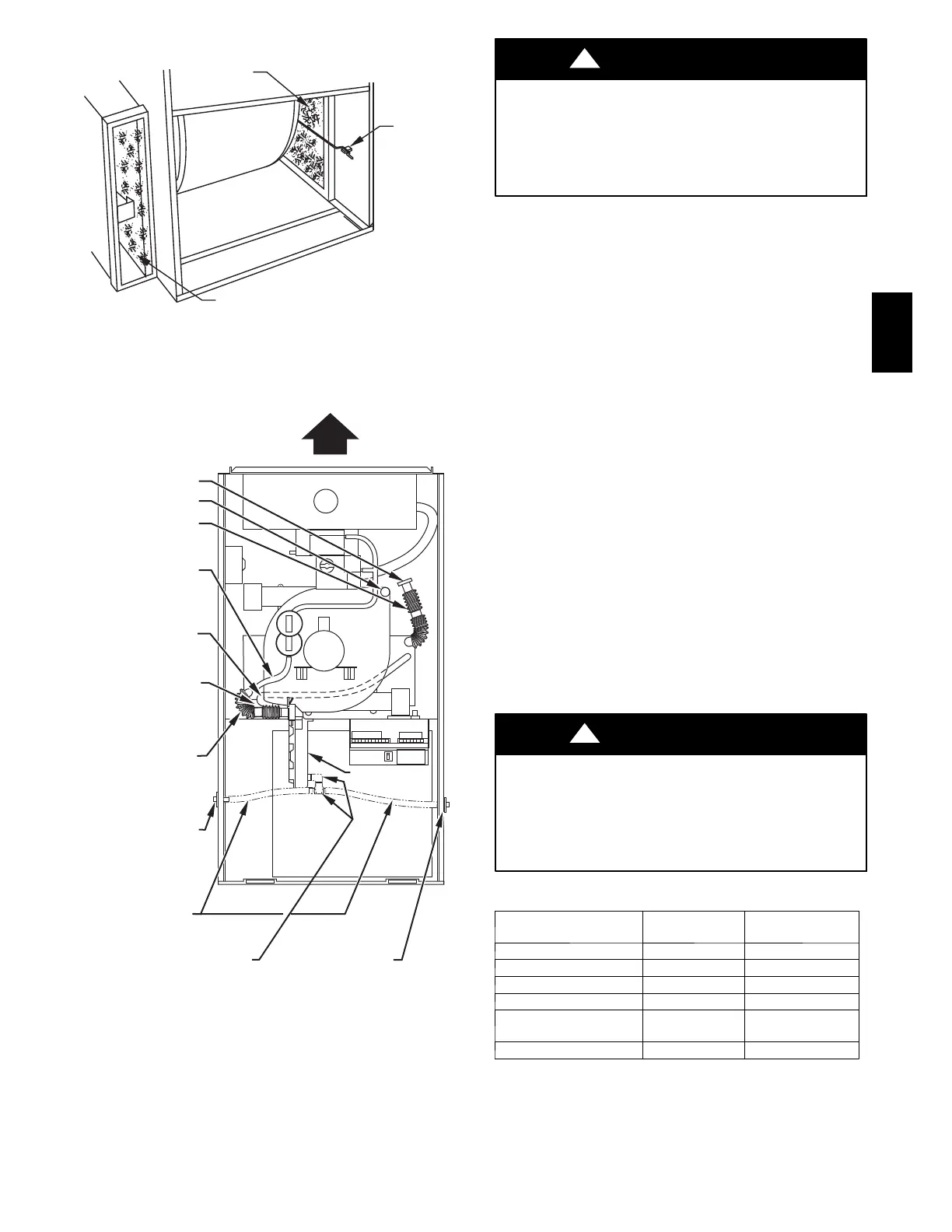

COLLECTOR BOX

TUBE (PINK)

COLLECTOR BOX

TUBE (GREEN)

INDUCER HOUSING

(MOLDED) DRAIN

TUBE (BEHIND

COLLECTOR BOX

DRAIN TUBE)

COLLECTOR BOX

DRAIN TUBE (BLUE)

FIELD-INSTALLED

FACTORY-SUPPLIED

DRAIN TUBE

COUPLING (LEFT

DRAIN OPTION)

FIELD-INSTALLED

FACTORY-SUPPLIED

DRAIN TUBE

FIELD-INSTALLED

FACTORY-SUPPLIED

1

⁄

2

-IN. CPVC STREET

ELBOWS (2) FOR

LEFT DRAIN OPTION

FIELD-INSTALLED

FACTORY-SUPPLIED

DRAIN TUBE

COUPLING (RIGHT

DRAIN OPTION)

CAP

COLLECTOR BOX

DRAIN TUBE (BLUE

& WHITE STRIPED)

PLUG

CONDENSATE

TRAP

A01030

Fig. 5 -- Factory--Shipped Upflow Tube Configuration

(Shown with Blower Access Panel Removed)

UNIT DAMAGE HAZARD

Failure to follow this caution may result in noise or furnace

component failure.

The blower wheel should not be dropped or bent as balance

will be affected.

CAUTION

!

g. Clean wheel per instructions on degreaser cleaner. Do not

get degreaser in motor.

9. Reassemble motor and blower wheel by reversing items 8b

through 8f. Ensure wheel is positioned for proper rotation.

Tighten setscrew to between 140--160 in.--lb torque.

NOTE: Be sure to attach ground wire to blower housing.

10. Reinstall blower assembly in furnace.

11. Reinstall control box, transformer, and door switch as-

sembly on blower shelf.

12. Reinstall condensate trap and tubing if previously removed.

a. Reinstall condensate trap in hole in blower shelf.

b. Connect condensate trap drain tubes. See Fig. 5 or tubing

diagram on main furnace door for proper tube location.

(1.) Connect 1 tube (blue or blue and white striped) from

collector box.

(2.) Connect 1 tube (violet or unmarked) from inducer

housing.

(3.) Connect 1 tube (relief port, green or pink) from col-

lector box.

NOTE: Ensure tubes are not kinked or pinched, as this will affect

operation.

c. Connect field drain to condensate trap.

13. Reconnect wires. Refer to furnace wiring diagram and con-

nect thermostat leads if previously disconnected. (See Fig.

16.)

NOTE: Refer to Table 3 for motor speed lead reconnection if

leads were not identified before disconnection.

UNIT DAMAGE HAZARD

Failure to adjust the heating speed may shorten heat exchanger

life.

Heating air speed selection MUST be adjusted to provide

proper temperature rise as specified on the rating plate.

CAUTION

!

Table 3 – Speed Selection

COLOR SPEED

FACTORY

ATTACHED TO

White Common Com

Black High Cool

Yellow Medium High Spare

Orange{ Medium H i g h --- G a s H e a t

Blue Medium Low

S p a r e / H i g h --- G a s

Heat

Red Low* L o w --- G a s H e a t

*Continuous blower speed.

{Available on 5---speed blowers only.

352AAV

Loading...

Loading...