Read carefully before carrying out installation and maintenance.

Operating Instructions

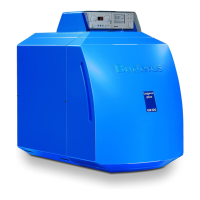

Low-temperature

oil/gas boiler

Logano G315

WARNING!

If installation, adjustment, modification, operation or maintenance of

the heating system is carried out by an unqualified person, this may

result in personal injury or property damage.

Precisely follow the instructions of this manual. If support or additional

information is required, contact a qualified service company, service

provider or the gas company.

WARNING!

Observe the safety instructions of this manual before commissioning the

heating device.

The operating manual is a component of the technical documentation

and must be handed over to the operator of the heating system. The

handling of the heating system according to the operating manual must

be explained to the owner or operator. Make sure that he has been

familiarized with all information required for the operation of the heating

system.

These instructions are available in English and French.

Please keep these instructions for future reference.

6 720 817 939-00.1T

Low temperature boilers for oil/gas fired power burners

6 720 817 940 (2017/02) US/CA