LOWLANDER MK4 MANURE SPREADER – INSTRUCTION & SPARES MANUAL

1.9 OPERATING INSTRUCTIONS FOR HORIZONTAL BEATERS

General use

The horizontal beater with spinner discs is designed primarily for wider spread patterns

and lower application rates for product such as chicken and turkey manure, however

long straw based materials can be spread effectively. It must be expected that

application rates maybe slower than a vertical auger spreader.

Adjustments for spread patterns

The position of the lower section of rear canopy and the angle of the blades on the discs

will affect the spread pattern and width.

Select a hole position that places the rubber strip over the middle of the discs for a

lighter application rates and wider widths. Adjust the hole position to move the rubber

strip rearwards for higher application rates e.g. for straw based materials. Excessive

rearward adjustment will cause the material to miss the discs and hit the ground

without being spread.

Each spinning disc is supplied with 2 blades on and the others loose; it has been proven

that many materials are spread more effectively with just 2 blades per disc.

1 To increase the width of the spread pattern adjust the angle of blades forward

on the disc.

2 If the spread pattern is light immediately behind the machine adjust the angle of

the blades back.

3 With 4 blades fitted it is possible to achieve an even spread by adjusting the

blades, as opposing pairs. i.e. Blade 1 and 3 in position 3 and blade 2 and 4 in

position 1.

4 When adjusting angle use the 2nd set of holes on the blade to keep the tip of the

blade on the edge of the disc

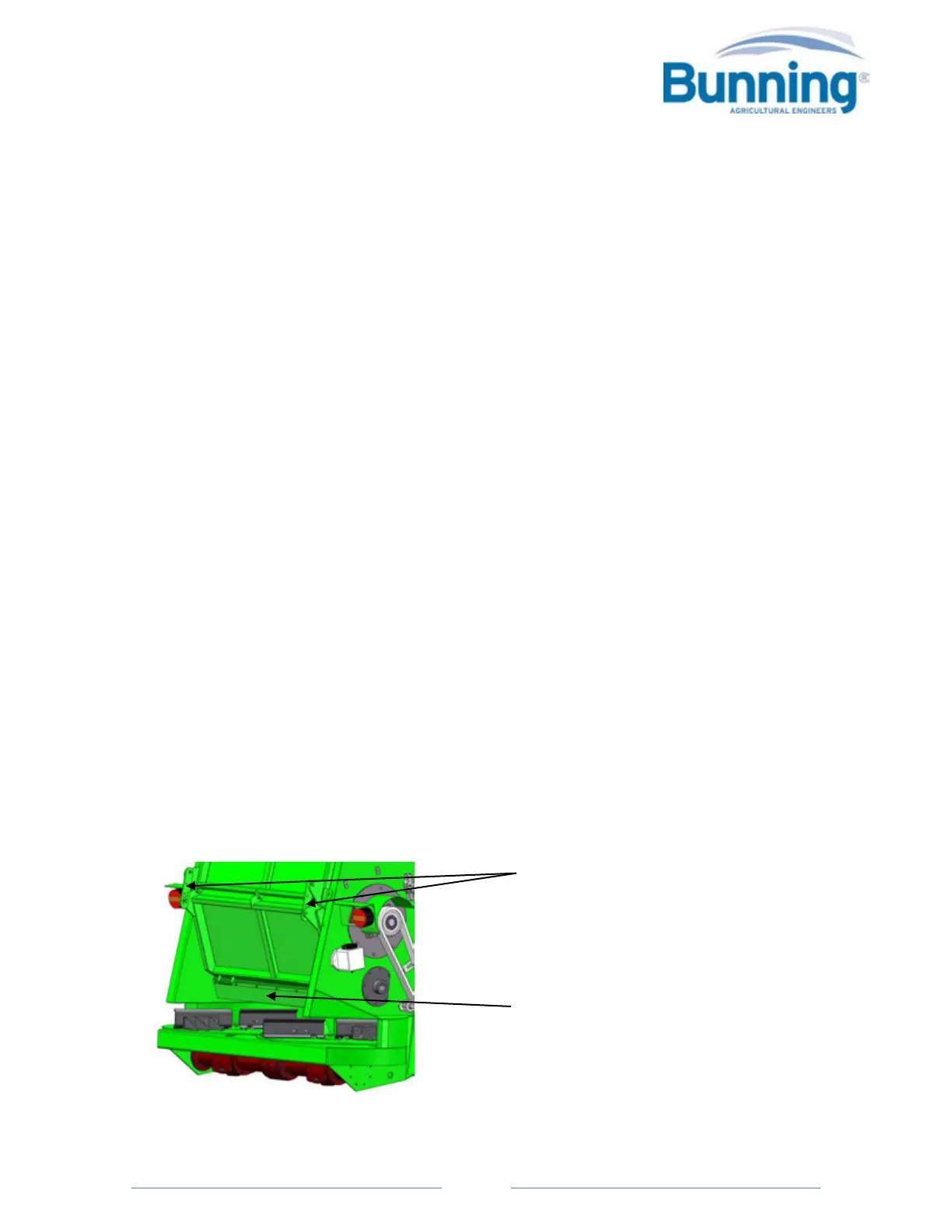

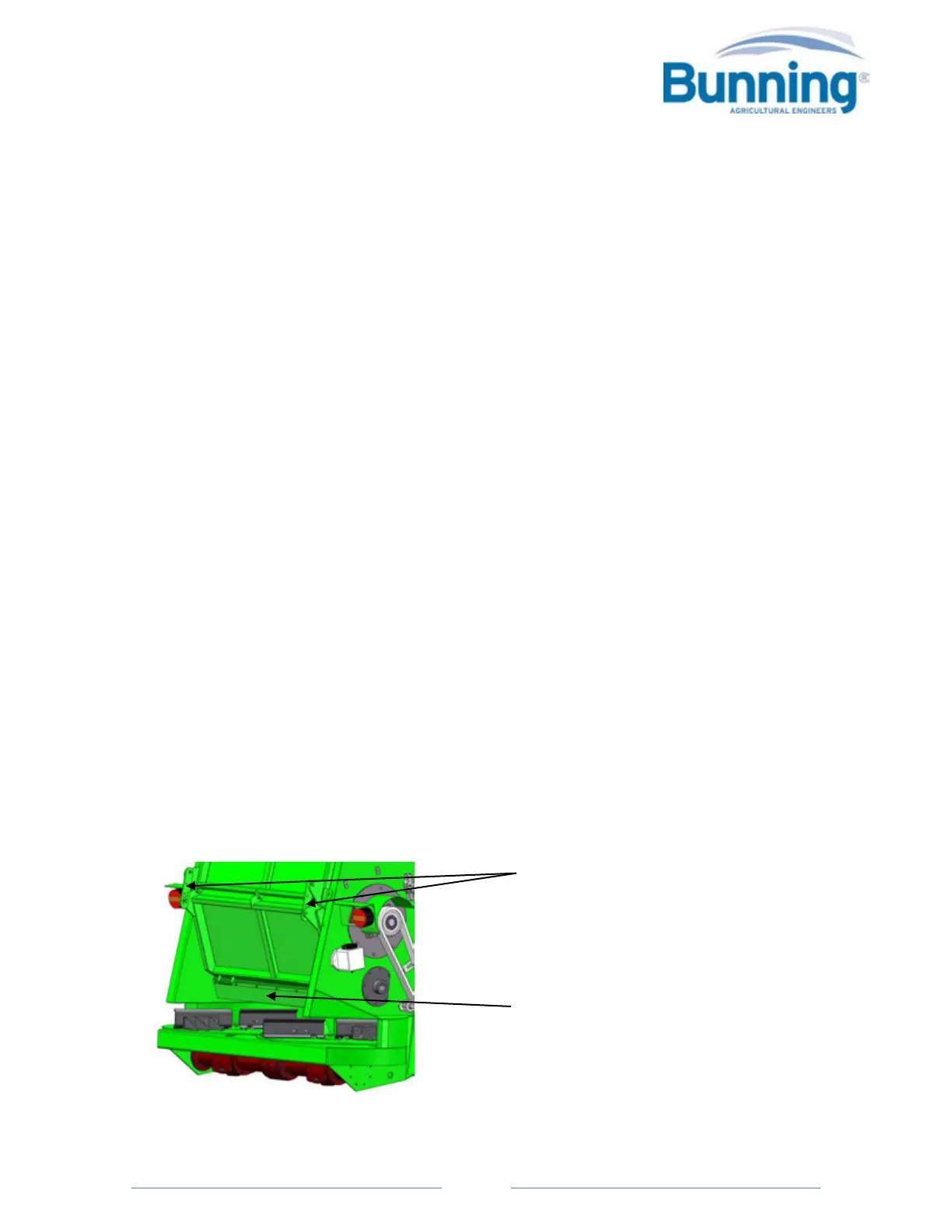

Change angle of lower

canopy here.

Rubber strip pointing

at the centre of the

spinning discs.

Loading...

Loading...