66

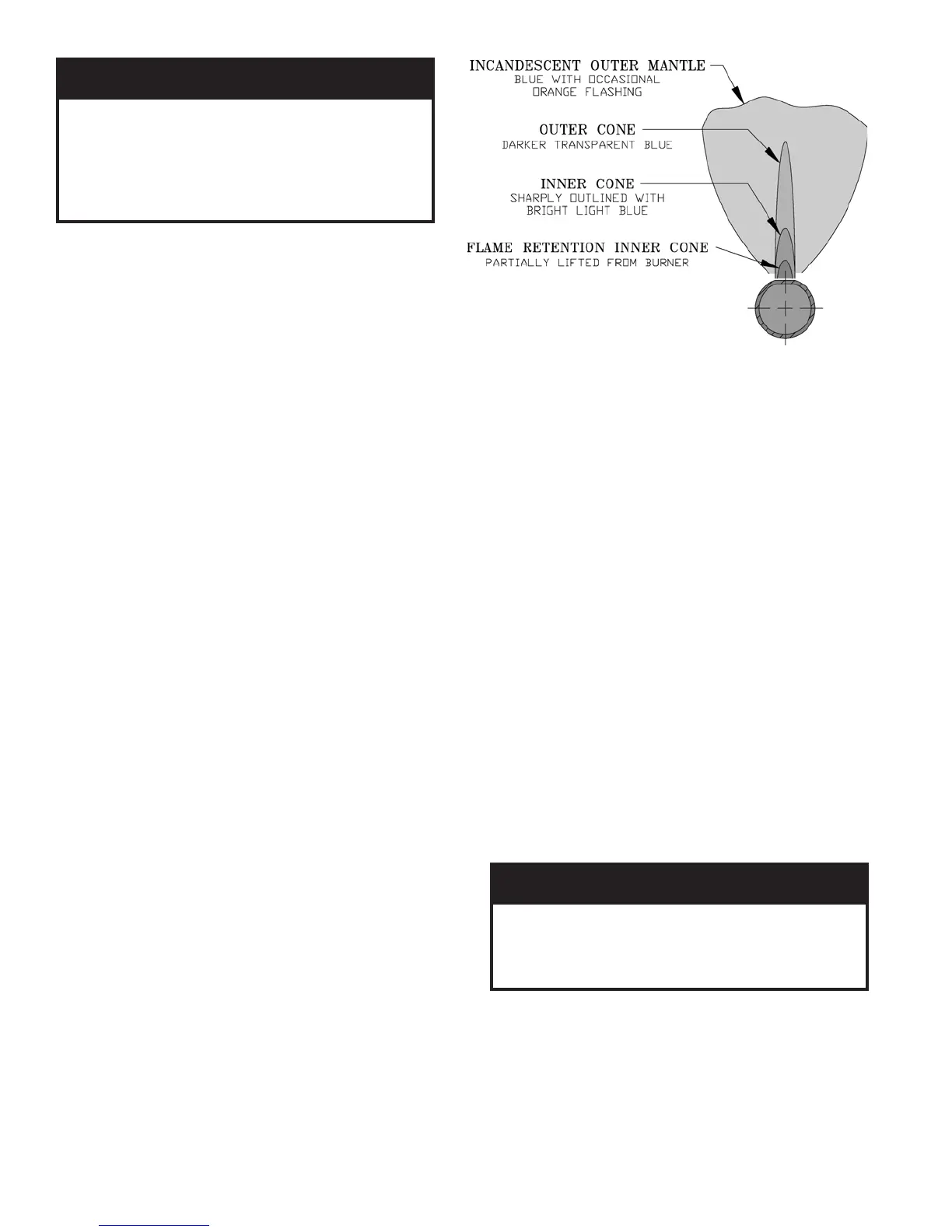

Yellow-tipping indicates lack of primary air. Improper

burner alignment on Main Burner Orifice will also

affect primary air injection. Adjust primary air as

follows:

a. Loosen lock screw.

b. Close air adjustment until yellow tips appear on

flames.

c. Slowly open air adjustment until clearly defined

inner cones are visible.

d. Tighten lock screw.

4. Adjust thermostat to normal setting.

J. Check thermostat or operating control operation.

Raise and lower temperature setting to start and stop

boiler operation.

K. Check ignition system shut-off.

1. Standing Pilot (24V): Disconnect thermocouple

lead at Gas Valve. Gas Valve must close and pilot

and main burners extinguish. If not, replace the

gas valve.

2. Honeywell EI: Disconnect ignitor/sensor cable

from Terminal (9) of ignition module. Gas valve

must close and pilot and main burners extinguish.

If not, measure voltage across gas valve terminals

"TH" and "TR".

a. If voltage is not present, replace gas valve.

b. If voltage is present, replace ignition module.

3. Johnson EI: Disconnect sensor cable from

Terminal 4 (SENSE). Gas valve must close and

pilot and main burner extinguish. If not, measure

voltage across gas valve terminals "TH" and "TR".

a. If voltage is not present, replace gas valve.

b. If voltage is present, replace ignition module.

4. EP and OP: Refer to instructions supplied with the

Honeywell RM7890 Burner Control.

L. Check Limit(s).

1. Adjust thermostat to highest setting.

2. Observe temperature gauge. When temperature

exceeds limit set point main burners should

extinguish.

Figure 59: Main Burner Flame

3. Adjust limit to setting above observed reading. Main

burners should reignite.

4. Adjust thermostat to lowest setting. Adjust limit to

desired setting.

M. Adjust gas input rate to boiler. Natural Gas.

1. Adjust thermostat to highest setting.

2. Check manifold gas pressure. Manifold pressure is

listed on rating label. Adjust gas valve pressure

regulator as necessary (turn adjustment screw

counterclockwise to decrease manifold pressure, or

clockwise to increase manifold pressure). If

pressure can not be attained, check gas valve inlet

pressure. If less than minimum gas supply pressure

listed on rating label, contact gas supplier for

assistance.

3. Clock gas meter for at least 30 seconds. Use Table

12 to determine gas flow rate in Cubic Feet per

Hour.

4. Determine Input Rate. Multiply gas flow rate by gas

heating value.

GNINRAW

lliwetartupnisagtsujdaylreporpoteruliaF

ehtfognirifrednurognirifrevonitluser

reliobefasnudnareporpmI.ecnailppa

.tluseryamnoitarepo

5. Compare measured input rate to input rate stated on

rating label.

a. Boiler must not be overfired. Reduce input rate

by decreasing manifold pressure. Do not reduce

more than 0.3 inch w.c. If boiler is still

overfired, contact your Burnham distributor or

Regional Office for replacement Gas Orifices.

NOITUAC

tnemnorivnenanireliobsihtgnitarepodiovA

yrd,srebifnoitalusniesool,tsudwaserehw

sireliobfI.tneserpera.cte,tsudllaw

renrubeht,snoitidnocesehtrednudetarepo

dnadenaelcebtsumstropdnaroiretni

.noitareporeporperusniotyliaddetcepsni

Loading...

Loading...