67

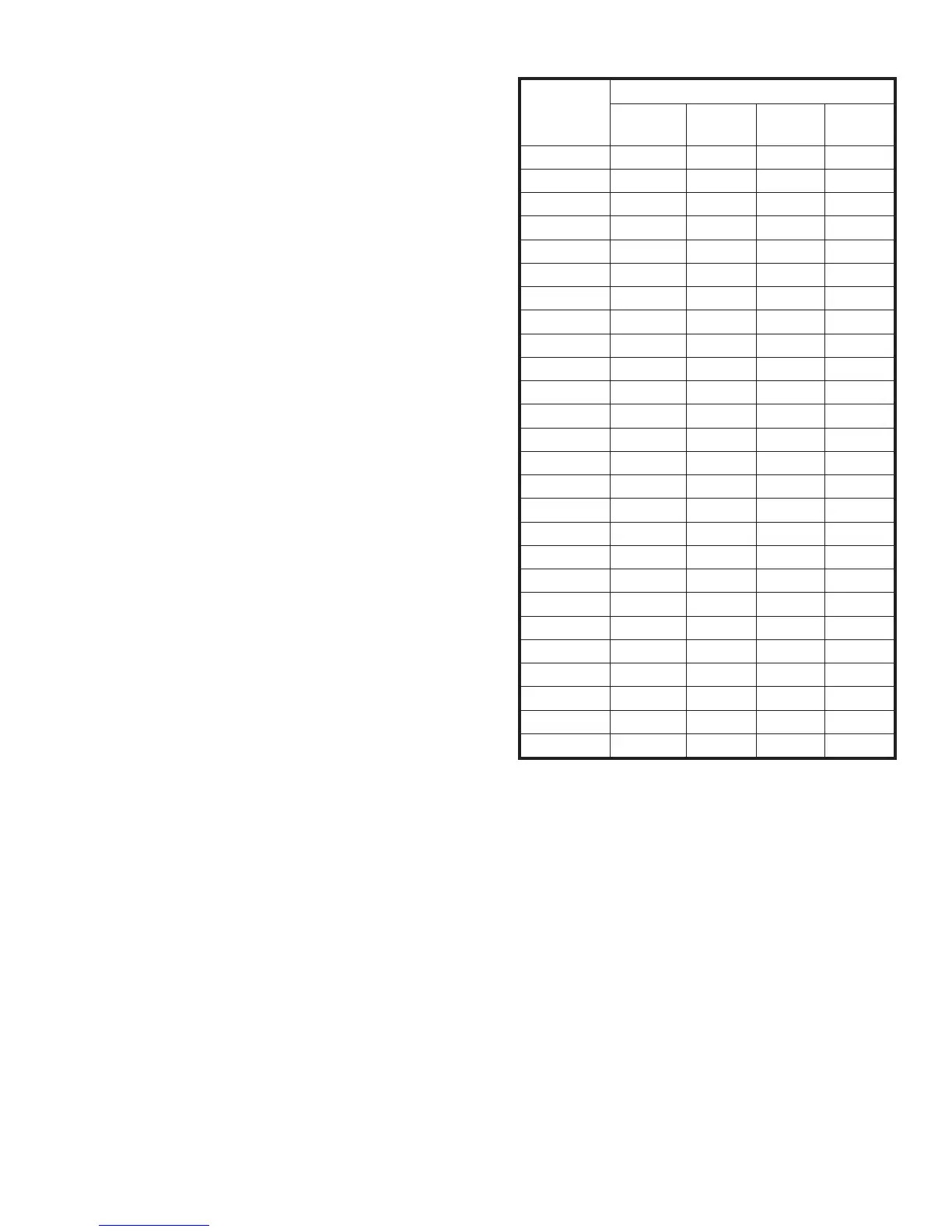

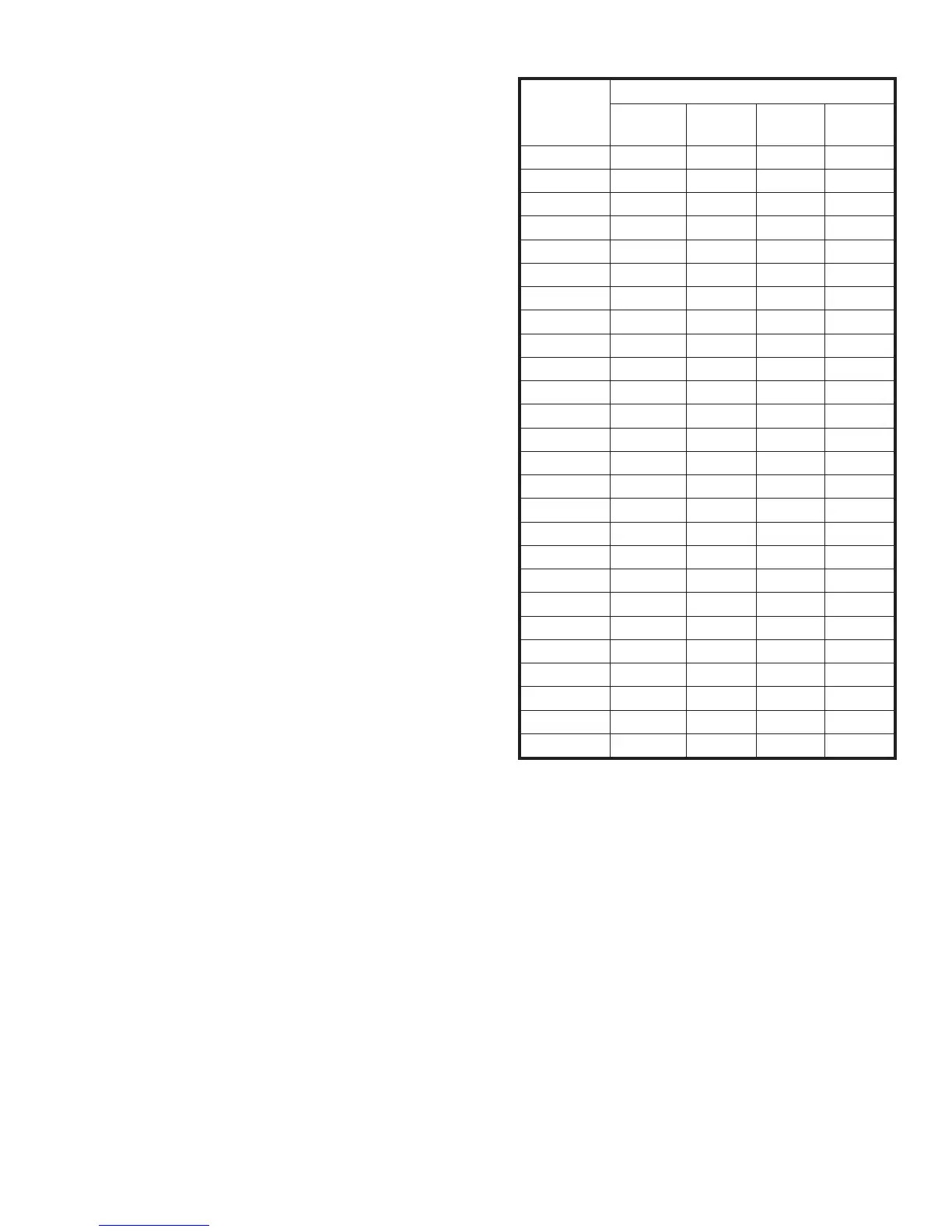

Table 12: Input Rate

b. Increase input rate if less than 98% of rating plate

input. Increase manifold gas pressure no more

than 0.3 inch w.c. If measured input rate is still

less than 98% of rated input:

i. Remove Main Burners per procedure in

Section IX: Service.

ii. Remove gas orifices. Drill one (1) drill size

larger (drill size is stamped on orifice, or

see Key No. 4E).

iii. Reinstall gas orifices and main burners.

Measure input rate.

6. Recheck Main Burner Flame.

7. Return other gas-fired appliances to previous

conditions of use.

N. Adjust gas input rate to boiler. LP/Propane.

1. Set thermostat to highest setting.

2. Adjust tank regulator for gas valve inlet pressure of

13.5 inches w.c. or less.

3. Gas valve has step opening regulator which initially

opens to 1.4 or 2.5 inch w.c. and steps to full

pressure after approximately 30 seconds. Check

manifold pressure after step has occurred. Adjust

gas valve pressure regulator as necessary for 10.0

inches w.c. (turn adjustment screw

counterclockwise to decrease manifold pressure, or

clockwise to increase manifold pressure). If 10.0

inches w.c. can not be attained, check gas valve

inlet pressure. If less than 11.0 inches w.c., contact

gas supplier for assistance.

O. Clean Heating System

Oil, grease, and other foreign materials which

accumulate in new hot water boilers and a new or

reworked system should be boiled out, and then

thoroughly flushed. A qualified water treatment

chemical specialist should be consulted for

recommendations regarding appropriate chemical

compounds and concentrations which are compatible

with local environmental regulations.

P. Check Damper Operation - If boiler is equipped with

vent damper, vent damper must be in open position

when boiler main burners are operating. Start boiler,

refer to instructions on damper to determine if damper

is in full open position.

Q. Install Front Removable Panel.

1. Engage top flange (longer of 2 flanges) behind

Upper Front Panel.

2. Swing lower portion of door toward boiler.

3. Lower door to engage bottom flange behind Lower

Front Tie Bar.

sdnoceS

enOrof

noituloveR

laiDreteMsaGfoeziS

flaH-enO

.tF.uC

enO

.tF.uC

owT

.tF.uC

eviF

.tF.uC

0306021042006

2365311522365

4335601212925

6305001002005

837459981474

045409081054

243468271034

441428461014

649387751193

847357051573

056327441063

255396831643

453376331333

652346921123

851326421013

060306021003

269285611092

469265211182

669245901372

868235601562

076215301752

275205001052

47428479342

67427459732

87326429132

08225409522

R. Combustion Chamber Burn-Off

1. The mineral wool combustion chamber panels

contain a cornstarch based binder that must be

burned out at installation to prevent odors during

subsequent boiler operation.

2. Ventilate the boiler room, set the high limit to its

maximum setting, set the thermostat to call for

heat.

3. Allow the boiler to fire for at least an hour or until

the odor from the cornstarch has dissipated.

4. Return the high limit and thermostat to their

desired settings.

S. Review User's Information Manual and system

operation with owner or operator.

Loading...

Loading...