59

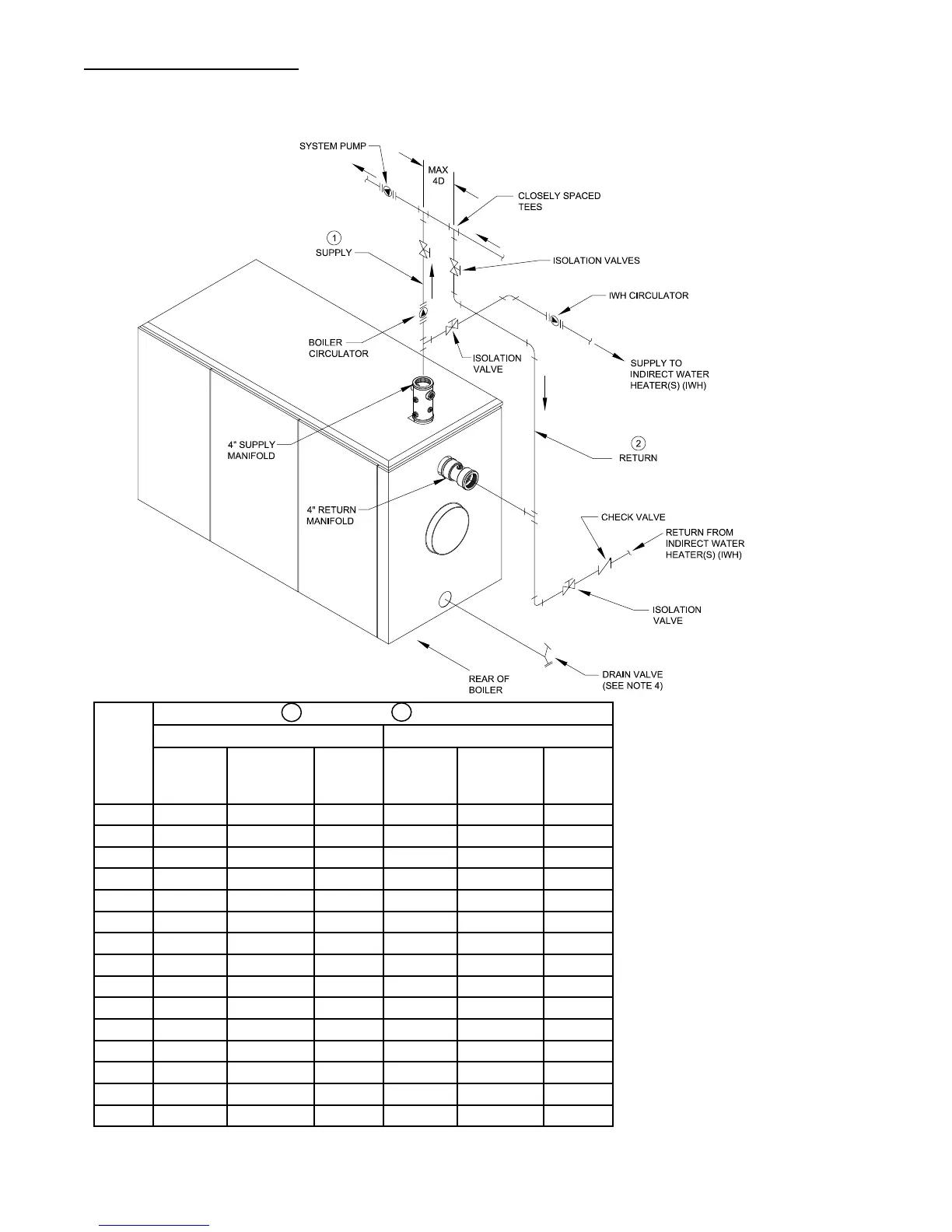

Figure 49a: Recommended MPC Minimum Piping - Single Boiler Application

NOTES:

1. All piping is schedule 40.

2. Pipe sizes listed are based on a 20°F

or 40°F Delta T (temperature rise

across the boiler).

Select one to match application.

3. When specied supply/return piping

size is less than 4”, install appropriate

size reducer directly onto boiler supply

and return manifolds.

4. Drain valve - ball valve preferable,

gate valve acceptable alternative

(supplied by others). Minimum valve

size per ASME Code is 3/4” NPT.

5. Swing joints may be piped over the top

of the boiler if space is limited.

6. System design must accommodate the

above Boiler Operating Requirements.

7. Diaphragm expansion tank shown, but

other types of air elimination systems

may be used.

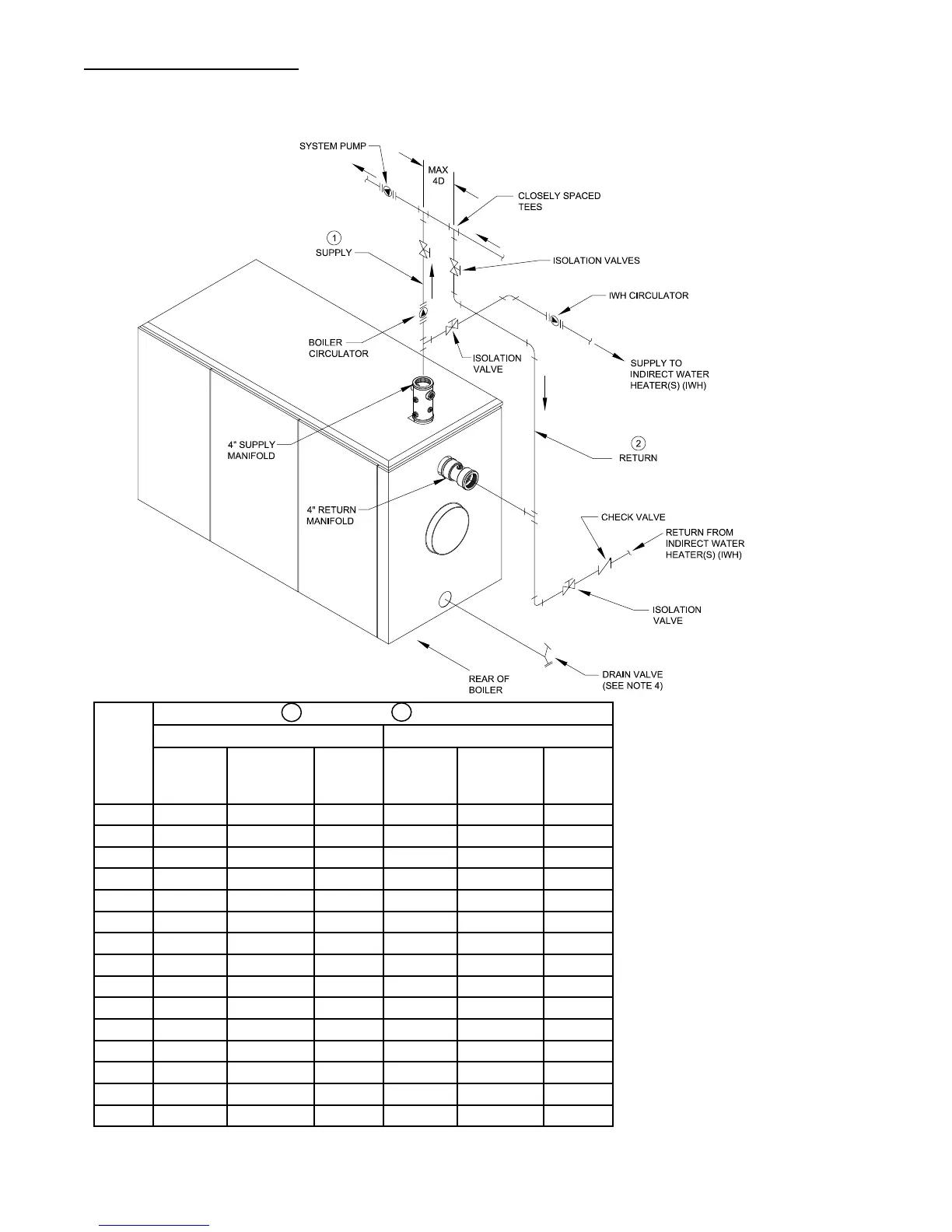

Boiler

Model

Supply / Return

20°F Rise 40°F Rise

Nom. I.D.

(Inch)

Water Side

Press. Drop

(Ft/Wtr)

Flow

Rate

(GPM)

Nom. I.D.

(Inch)

Water Side

Press. Drop

(Ft/Wtr)

Flow

Rate

(GPM)

MPC4 2 1.9 42.4 1½ 0.9 21.2

MPC5 2 2.6 65.2 1½ 1.6 32.6

MPC6 2 3.3 83.7 1½ 2.3 41.9

MPC7 2½ 4.0 102.3 1½ 3.0 51.2

MPC8 2½ 4.7 120.9 2 3.7 60.5

MPC9 3 5.4 139.6 2 4.4 69.8

MPC10 3 6.1 158.1 2 5.1 79.0

MPC11 3 6.8 176.7 2 5.8 88.3

MPC12 3 7.5 195.2 2½ 6.4 97.6

MPC13 4 8.2 213.8 2½ 7.1 106.9

MPC14 4 8.9 232.3 2½ 7.8 116.1

MPC15 4 9.6 250.9 2½ 8.5 125.5

MPC16 4 10.3 269.5 3 9.2 134.8

MPC17 4 11.0 288.1 3 9.9 144.1

MPC18 4 11.7 306.6 3 10.6 153.3

1

2

Loading...

Loading...