Commissioning | 6

Instruction Manual PANDA WV 0250-2000 C_EN_en 13 / 24

NOTICE

Lubricating a dry running machine (compression chamber).

Risk of damage to the machine!

• Do not lubricate the compression chamber of the machine with oil or grease.

• Make sure that the installation conditions (see Installation Conditions [►7]) are met.

• Switch on the machine.

• Make sure that the maximum permissible number of starts does not exceed 6 starts

per hour. Those starts should be spread within the hour.

• Make sure that the operating conditions comply with the Technical Data [►22].

• After a few minutes of operation, perform an Oil Level Inspection [►15].

As soon as the machine is operated under normal operating conditions:

• Measure the motor current and record it as reference for future maintenance and

troubleshooting work.

6.1 Compression Chamber Flushing

Depending on the process type (very demanding application), flushing through the com-

pression chamber (cylinder + lobes) might need to be performed. Seek advice from your

Busch representative.

NOTICE

Flushing without barrier gas.

Risk of damage to the machine!

• The flushing process can pass over into the bearings and the oil chambers!

Do not perform flushing without using the barrier gas.

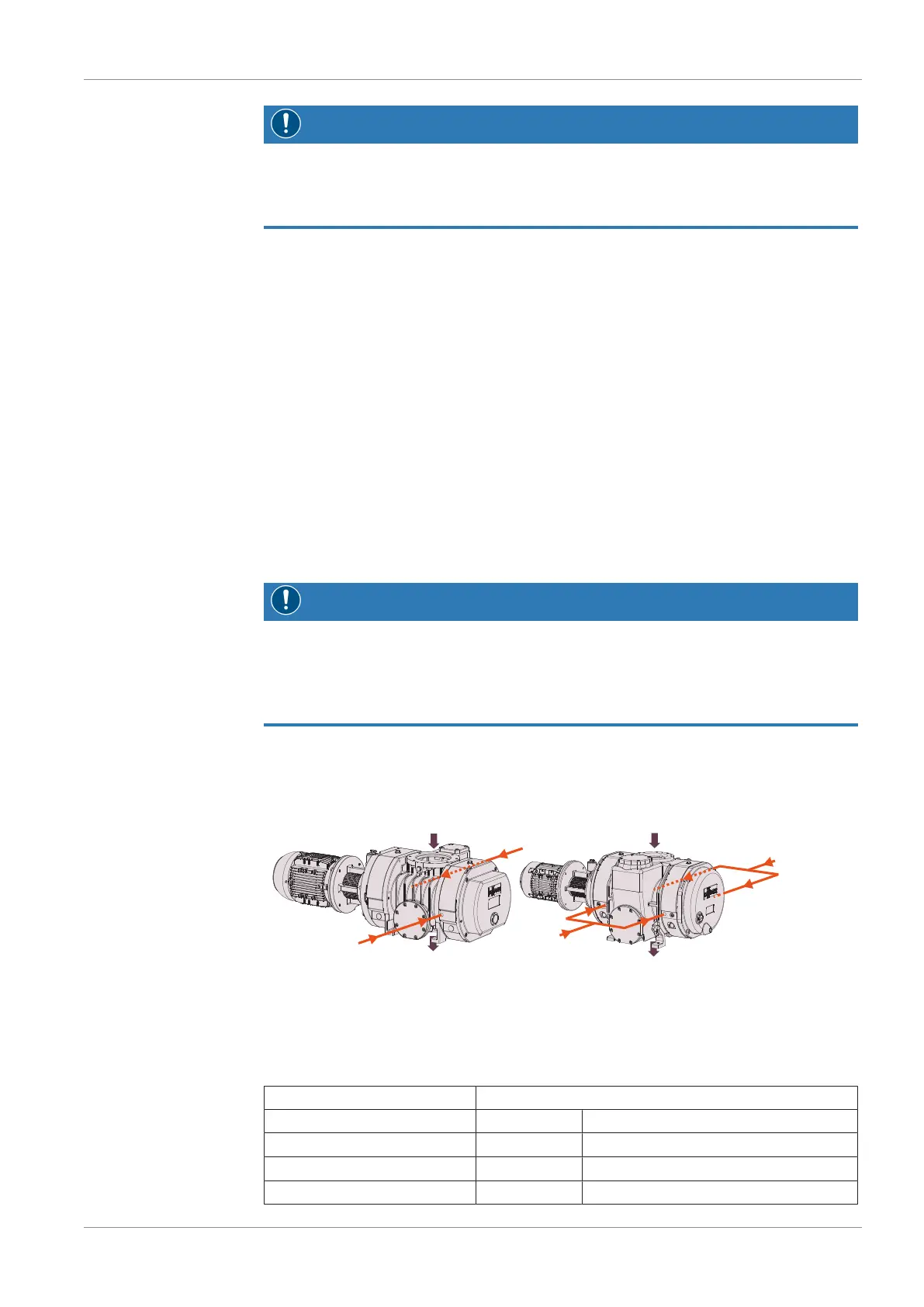

Beforehand, a barrier gas must be connected according to the following illustration and

recommendations:

Process flow

inlet (IN)

Process flow

outlet (OUT)

2x Barrier gas

connection (BGC)

1x Barrier gas

connection (BGC)

2x Barrier gas

connection (BGC)

Process flow

outlet (OUT)

Process flow

inlet (IN)

1x Barrier gas

connection (BGC)

Barrier gas configuration for WV 0250-1500 C Barrier gas configuration for WV 2000 C

Connection size:

– 2 x G3/8 (BGC) for WV 0250-1500 C

– 4 x G3/8 (BGC) for WV 2000 C

Barrier gas requirements:

Gas type Dry nitrogen, air or other suitable gas

Gas temperature °C 0 ... 60

Filtration µm ≤ 5

Gas pressure bar ≥ Pressure of flushing fluid + 1 bar

Recommended flow rate SLM* 30

Loading...

Loading...