Maintenance | 7

Instruction Manual PANDA WV 0250-2000 C_EN_en 15 / 24

7.1 Maintenance Schedule

The maintenance intervals depend very much on the individual operating conditions. The

intervals given below are considered as starting values which should be shortened or ex-

tended as appropriate. Particularly harsh applications or heavy duty operation, such as

high dust loads in the environment or in the process gas, other contamination or ingress

of process material, can make it necessary to shorten the maintenance intervals signifi-

cantly.

Interval Maintenance work

Monthly

• Check the oil level, see Oil Level Inspection [►15].

• Check the machine for oil leaks - in case of leaks have

the machine repaired (contact Busch).

After the first 500 hours • Change the oil of the gear and bearing housings

(both sides), see Oil Change [►16].

Every 6 months • Perform an oil inspection; change it if the oil has

changed its initial colour, see Oil Colour Inspection

[►15].

Every 5000 hours, at the latest

after 1 year

• Change the oil of the gear and bearing housings

(both sides)

• Clean the magnetic plugs (MP)

Every 16000 hours, at the least

after 4 years

• Have a major overhaul on the machine (contact

Busch).

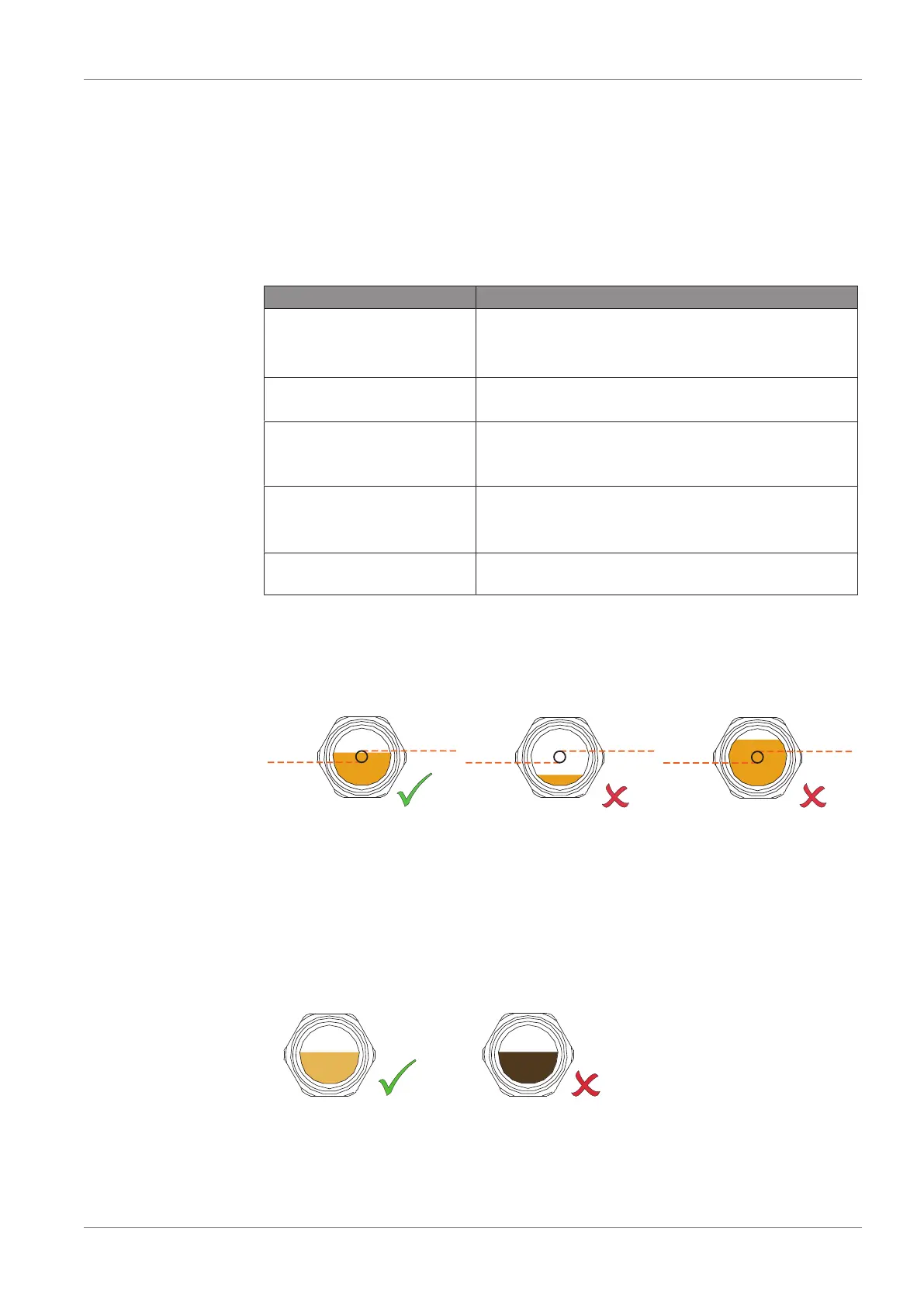

7.2 Oil Level Inspection

• Shut down the machine.

• When the machine is stopped, wait 1 minute before checking the oil level.

• Fill up if necessary, see Oil Filling [►9].

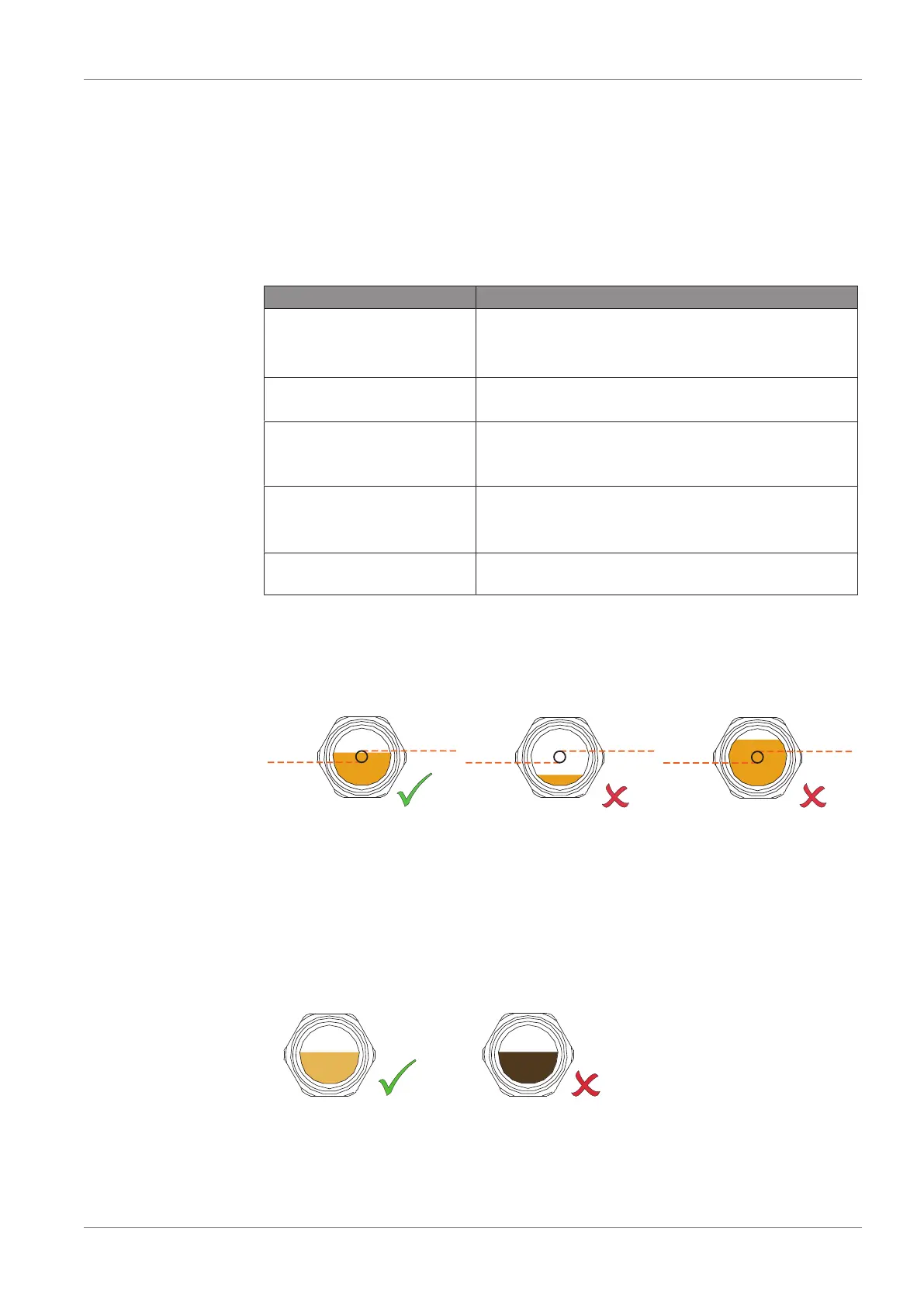

7.3 Oil Colour Inspection

• Make sure that the oil is either light or transparent.

If the oil becomes dark or looks different from the initial colour:

• Change the oil immediately, see Oil Change [►16].

• See Oil Change [►16].

You can consult your Busch representative in order to find out why this colour change

has occurred.

Loading...

Loading...