EN

33

s¬Generally, we recommend the operation with softened feed

water to achieve an extending of the life and reliability of the

RO membranes.

D

All hoses have been connected and are watertight.

When installing the optional “high-efficiency“ WCF -

Kit, the enclosed operation manual must be observed!

s¬0LEASE¬OPEN¬THE¬VALVE¬FOR¬THE¬FEED¬WATER¬SUPPLY

s¬#ONNECT¬THE¬2/¬UNIT¬TO¬THE¬POWER¬SUPPLY¬6¬(Z

DThe functions of the control unit and software configuration

are described in Part 3.1 - 3.8.

s¬7E¬RECOMMEND¬THAT¬THE¬PUMP¬PRESSURE¬IN¬EACH¬OPERATING¬

mode to set at approx. 8.1bar!

s¬)NSTRUCTIONS¬FOR¬THE¬7#&¬KIT¬INSTALLATION¬AVAILABLE¬IN¬Part 5.3.

s¬Note: Discard the first produced permeate during the first

10 minutes after any new installation/first commissioning or

at any membrane replacement.

Note: Please run the RO unit a few days to reach the

full performance (WCF and permeate quality).

Note: A drop of temperature by 1°C will reduce the

permeate output of the membranes by approx. 3.0%.

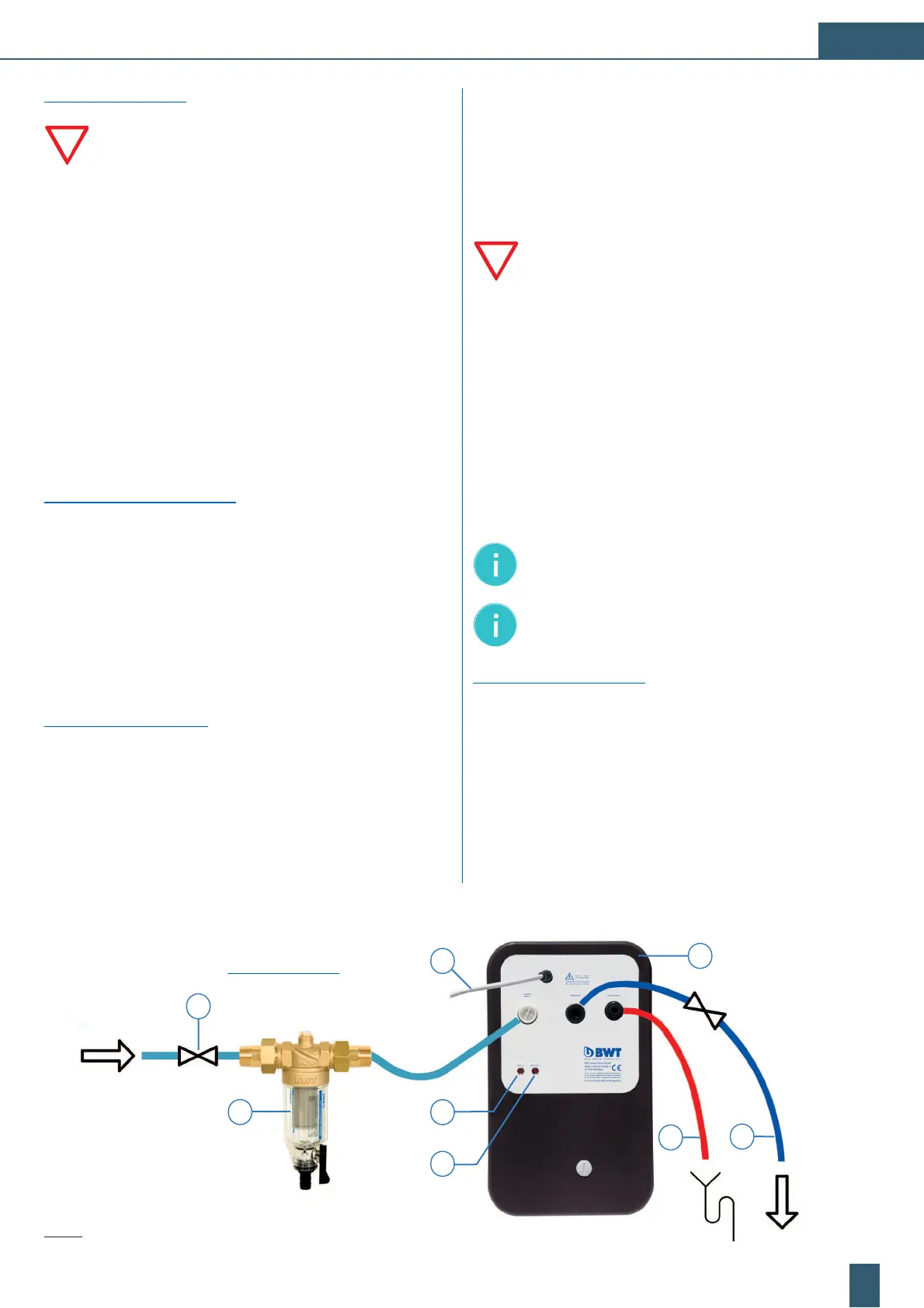

Possible installation layout:

1

BWT PERMAQ

®

compact 2 - 6 reverse osmosis

2 External pre-filter (not included in the delivery)

3 Permeate outlet ready for the connection to the consumer/tank

4 Stop valve for feed water and permeate hose

5 Mains plug, cable length 1.8m

6 Concentrate outlet

7 Optionally: External contacts (INPUT), start/stop

8 Optionally: External contacts (OUTPUT), alarm output

Hydraulic installation:

Please respect the general installation instructions for the

preparation of water installations as well as the general

hygiene requirements.

s¬0LEASE¬READOBSERVE¬ALL¬APPLICABLE¬SPECIlCATIONS¬OPERATING¬

and safety instructions prior to the installation.

s¬0LEASE¬USE¬ONLY¬APPROVED¬mEXIBLE¬HOSES¬ACCORDING¬TO¬

the DVGW W 543 requirements.

s

Please adhere to all dimensions as well as bending radius in

the assembly of the flexible tubes and connection sets.

s¬4HE¬"74¬0%2-!1

®

compact 2 - 6 device line is to be installed

and operated vertically.

s¬4HE¬UNIT¬MAY¬NOT¬BE¬CONNECTED¬TO¬THE¬WATER¬MAINS¬BY¬RIGID¬PIPES

s¬!¬HYDROPHORE¬OR¬A¬STORAGE¬TANK¬WITH¬A¬BOOSTER¬PUMP¬COULD¬

be installed in the permeate line between the RO unit and the

consumer, if depending on the application a short-term peak

flow is required.

Connection to the water pipe:

s¬4HE¬DEVICE¬HOSES¬MUST¬BE¬INSTALLED¬IN¬A¬mEXIBLE¬MANNER¬

(without an

y tension) to maintain a safe operation.

s¬#HECK¬ALL¬WATER¬CONNECTIONS¬TO¬ENSURE¬THAT¬THEY¬ARE¬TIGHT¬AND¬

waterproof.

s¬'UIDE¬THE¬mEXIBLE¬CONCENTRATE¬HOSE¬WITH “free flow“ condition

to the on-side connection of the drain pipe (with a slope of 1%)

and fasten it. The “flexible“ hoses must not have any bends or

cross-sectional constrictions. Observe during the installation that

the concentrate- and permeate hoses were correctly connected.

Notes for initial operation:

s¬#ONNECT¬THE¬2/¬UNIT¬WITH¬THE¬ELECTRICAL¬POWER¬SUPPLY¬

(230V, 50Hz). The wall socket has to be earthed.

s¬0LEASE¬CONSIDER¬THE¬INDIVIDUAL¬MANUAL¬OF¬THE¬external pre-filter.

s¬4HE¬water hardness can vary in different areas.

3

6

1

4

Fig. 3: Installation scheme / example

2

'ZVGTPCNRTGƂNVGT

BWT Protector Mini C/R 1/2“ ;

BWT accessories

5

7

8

Loading...

Loading...