Thermal disinfection

The temperatures and corresponding times for disinfection of the

system must be selected according to the type of installation and

its intended use. To meet the requirements of the most recent world

legislation on this matter, the following criteria can generally be

followed:

T = 70°C for 10 minutes

T = 65°C for 15 minutes

T = 60°C for 30 minutes

Thermal disinfection is generally carried out at times when there is

less demand on the system, for example at night; this is to minimize

the risk of users being scalded. It is recommended to perform thermal

disinfection every day and at least once a week.

Maintenance

Tests are carried out while in service, to regularly monitor the

performance of the mixing valve, since any loss of performance may

indicate the need for maintenance of the valve and/or the system.

During these tests, if the temperature of the mixed water is found

to have changed significantly compared with previous tests, we

recommend referring to the sections on installation and commissioning

and carrying out maintenance.

We recommend carrying out the following checks periodically to ensure

that the valve continues to deliver optimum levels of performance. At

least every 12 months, or more frequently if required.

1) Check and clean the filters in the system

2) Check that any check valve installed at the inlet of the Caleffi valve

is functioning correctly, and there are no leaks caused by dirt.

3) Once the maintainable components have been checked, we

recommend following the commissioning procedure again.

On the system log book, record all operations carried out.

Functional faults

A special set of alarms has been fitted to help manage possible faults

that can occur in the device. Refer to the dedicated section of the

"Programming Manual" (code H0003581).

10 11

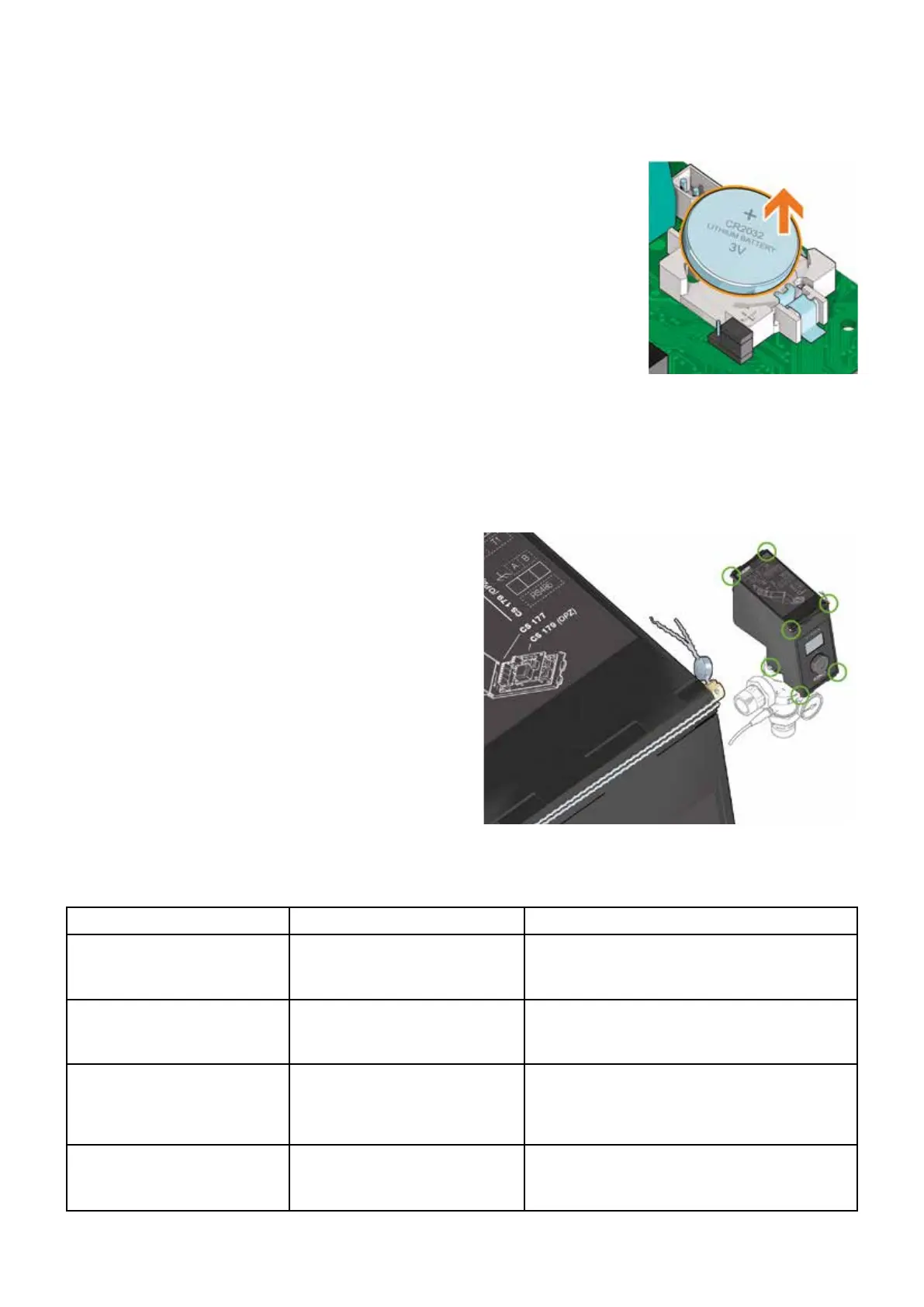

Buffer battery replacement procedure

If necessary, it is possible to replace the buffer battery removing the

low battery from its seat and inserting the new one without forcing.

Battery type CR2032.

Problem Cause Solution

Hot water supplied to cold water taps a) Inlet check valves not operating

correctly or seals worn/damaged

b) Check valves not tted

Replace damaged check valves

Install check valves

Mixed water temperature uctuations a) Incorrect inlet water temperatures

b) Inlet water supply failure

c) Bad commissioning

Restore inlet conditions to within valve specication range

Incorrect valve outlet ow rate a) Insufcient water supply

b) Inlet water temperature/pressure

uctuations

c) Adverse conditions due to other water

draw off points in the system

Stabilise supply conditions at the inlet

No valve outlet ow a) In-line strainers obstructed

b) Insufcient supply pressure

c) Dirt obstructing water ow through the

valve

Clean the strainers

Restore supply conditions

Remove dirt/scale from the valve

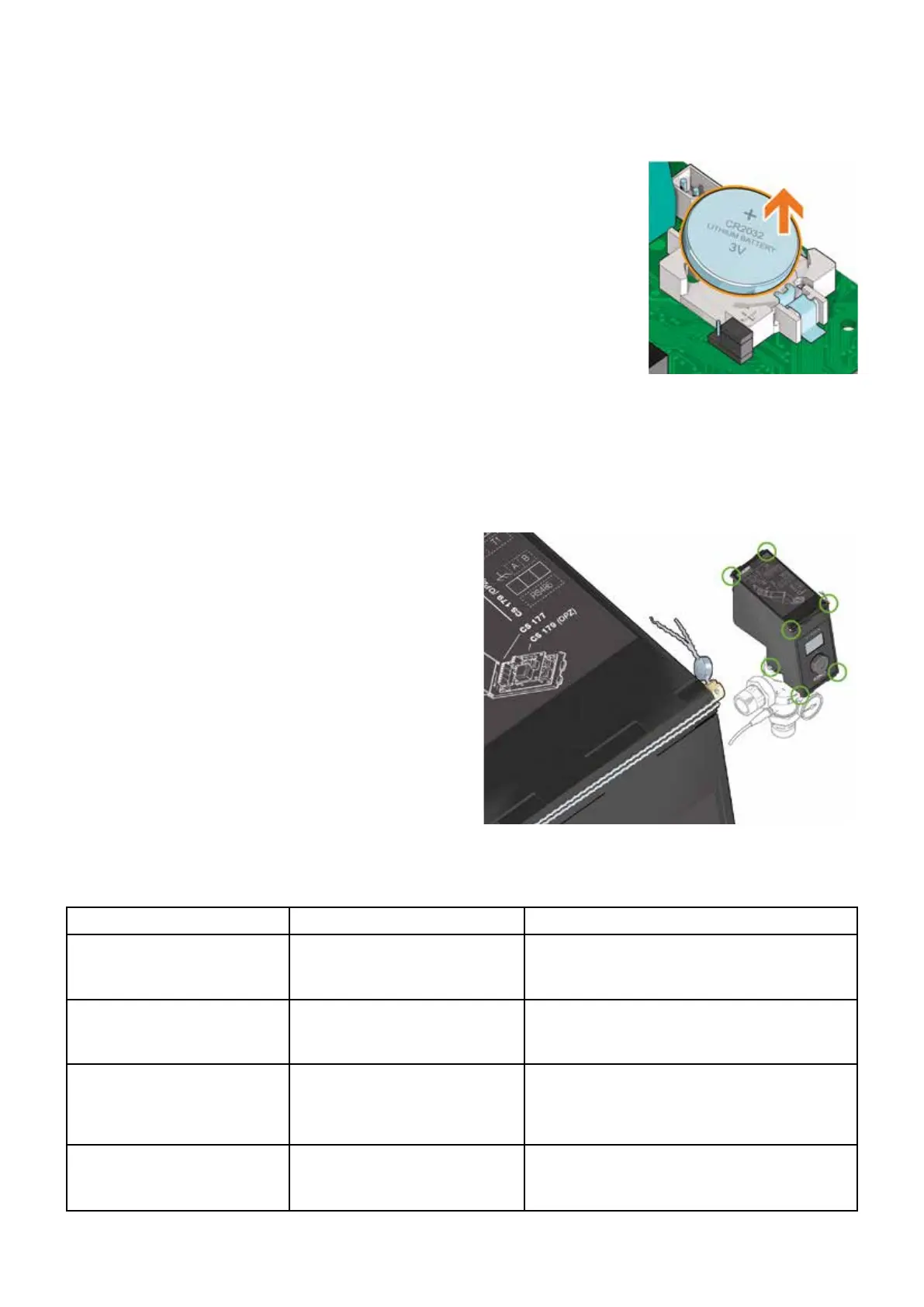

Seals

The screws are fitted for the installation of anti-tampering seals.

Troubleshooting

In normal operating conditions, Caleffi series 6000 hybrid electronic mixing valves provide outstanding performance. However, in special circumstances

when our maintenance schedule is not observed, the following problems may arise:

Loading...

Loading...