7

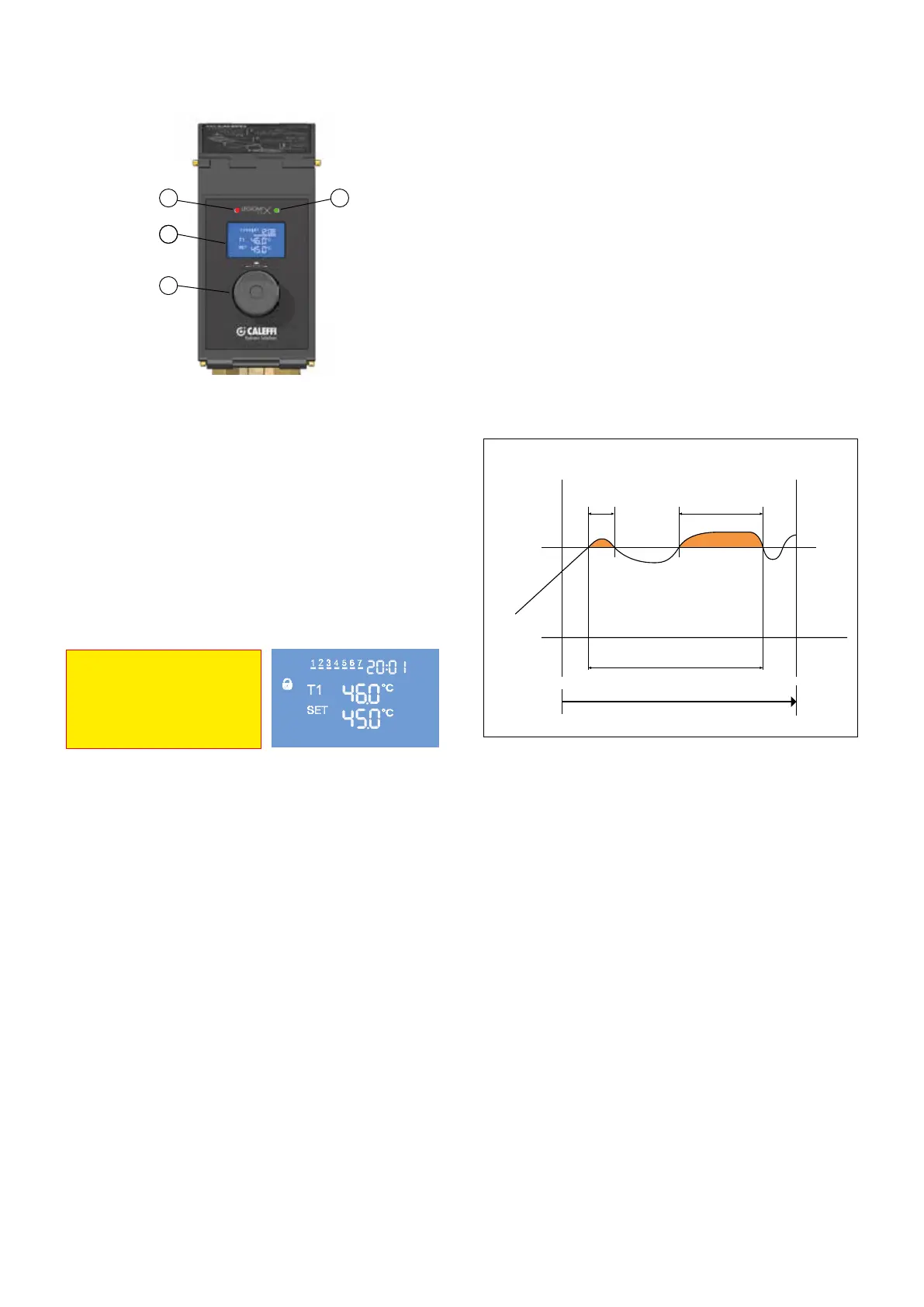

Front panel

1 LCD display

2 Control knob

3 Green LED: - On (network presence)

4 Red LED: - Fixed (disinfection or thermal shock in progress, full

scale acquisition)

- Flashing (alarm condition)

Indication on LCD display

On the front of the device there is a backlit alphanumeric LCD

display for parameter setting, interventions programming, working

statuses and alarms display.

Navigating through appropriate menus, using the control knob

only, it is possible to configure the device and set the various

parameters.

Operating status

Depending on the times and the programs that have been set, the device

may be in one of the following operating modes:

• Regulation

• Disinfection

• Thermal shock*

• Zero and full scale acquisition

*(this function has priority over the disinfection/regulation).

In the event of anomalies, the device manages and signals an alarm trying

to set into a safety condition for the user. The device is equipped with a

non-rechargeable battery that keeps the clock working in the event of

electric supply failure.

Regulation

The electronics must adjust the flow temperature through the actuator in

order to reach the working set-point. The electronic actuator adjusts the

flow so as to have a temperature centered in a suitable working range,

within which the fine and dynamic adjustment is made by the thermostat.

The mixing temperature is set through the interface. The management

system always checks in real time the flow temperature detected by

the probe: if the flow temperature deviates excessively from the set

value, a correction is made through the electric motor. In the case of

installation with a return probe present, it is not used for the water mixing

temperature adjustment.

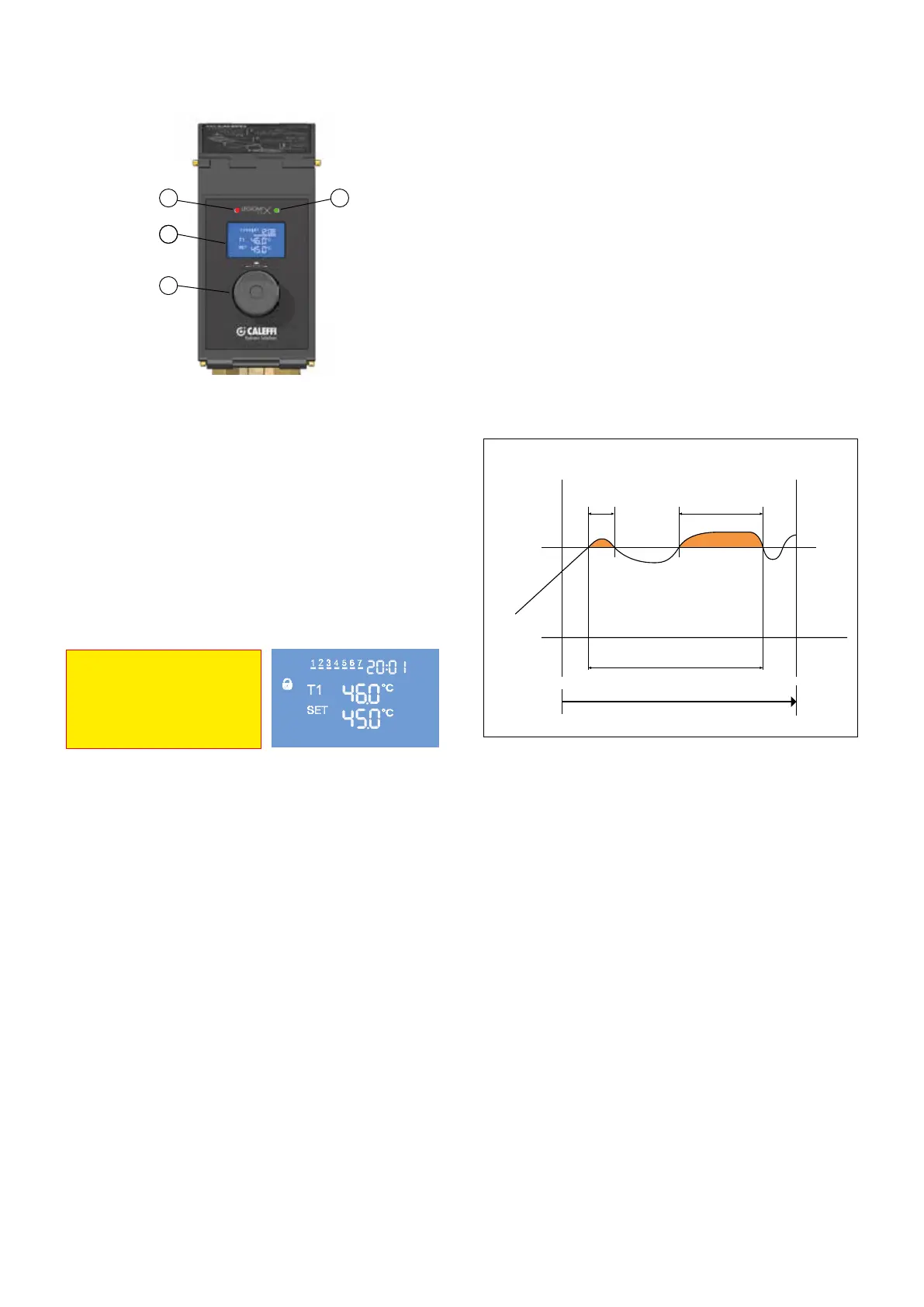

Disinfection

In this mode, the device performs thermal disinfection, which consists in

raising the mixed water temperature for a defined period of time.

The following can be set:

- Days of the week for performing the disinfection

- Minimum disinfection temperature

- Disinfection start time

- Minimum stay time above the minimum disinfection temperature in

order to evaluate the successful outcome of the disinfection

- Maximum time within which it is possible to perform the disinfection

The disinfection can be:

- Programmed: it starts in the days and hours set

- Activated through the control: it can be controlled by the device from

the "Controls submenu" or remotely through optional board

- Activated by IN1 inlet

The disinfection in progress OUT3 relay and the recirculation pump

management OUT2 relay are always activated during the disinfection.

If the disinfection temperature does not last for sufficient time and the

maximum available time is exceeded, the disinfection will be considered

as failed by signalling the relevant alarm.

8

Thermal shock

In this mode, the device raises the flow temperature to the set value for

a certain period of time. The disinfection in progress OUT3 relay and the

recirculation pump management OUT2 relay are always activated during

the thermal shock.

Zero and full scale acquisition

In the zero acquisition mode, the device totally closes the adjusting screw

to check the correct phasing between the motor and the valve. In full

scale acquisition mode, the device fully opens the adjusting screw so

it can check all the stroke (potentially hazardous condition indicate with

fixed red LED). The zero and full scale acquisition controls are activated

during the installation or after the "Reset alarms” control.

Additionally, the zero acquisition mode is activated whenever an electric

supply failure occurs for at least 60 minutes and at the outlet from any

disinfection/thermal shock. It is recommended to perform the full scale

acquisition with shut-off valves closed at the mixing valves inlets.

Reset

In the menu there is a special control to reset to the initial conditions. The

history is not reset.

Test

The device performs full strokes in order to check that there are no

obstructions during the motor opening and closing strokes. The display

shows the encoder steps and the power consumption (mA). It is possible

to interrupt the test function at any time pressing the control knob.

t

1

t

2

Σ t

s

> minimum disinfection time

minimum

disinfection

temperature

CHECK ON DISINFECTION

Temperature [°C]

Time [s]

Disinfection start

Disinfection end

maximum disinfection time

4

1

2

3

For management and programming

of the device refer to the

"Programming Manual"

code H0003581

Loading...

Loading...