When the pump remains inactive it must be emptied

completely if there is a risk of freezing

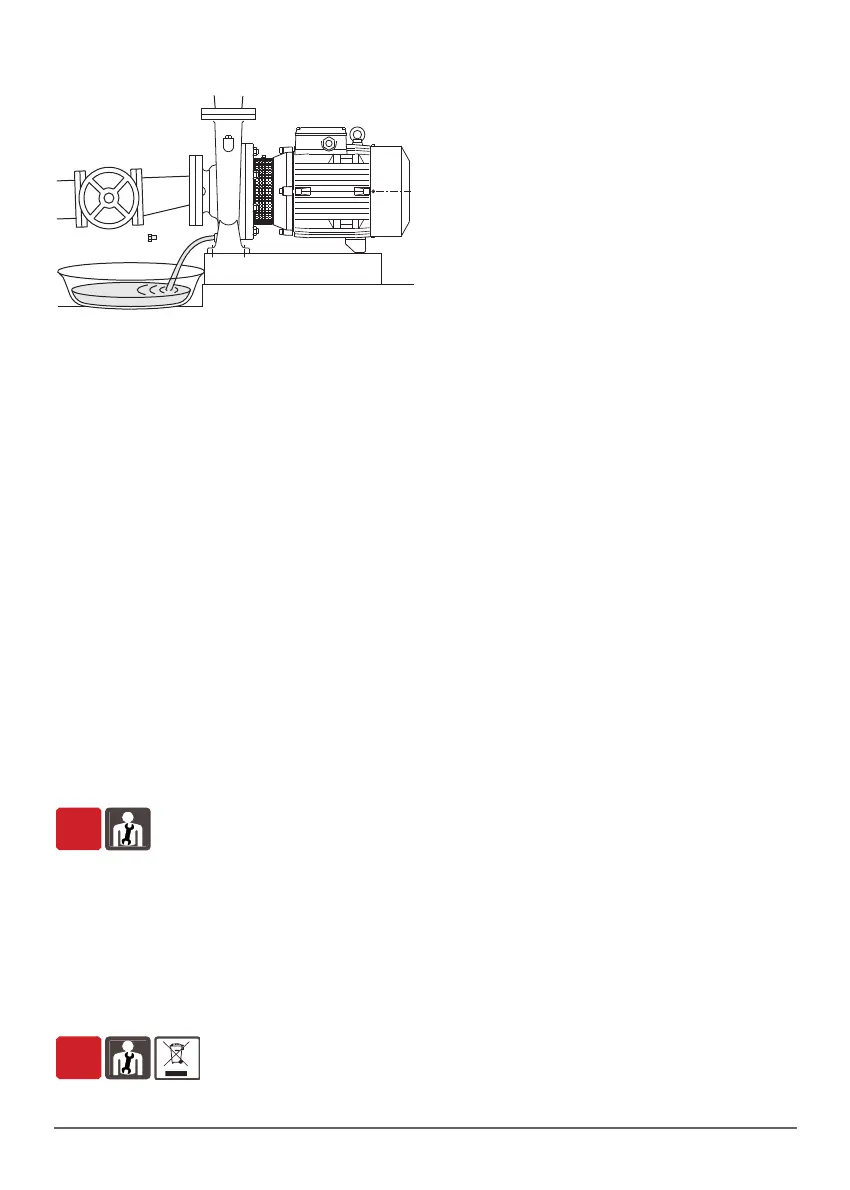

Fig. 4

.

Before restarting the unit, check that the shaft is not

jammed and fill the pump casing completely with liquid.

8.2

Maintenance

Pumps with packing seal

First loosen the gland slightly so that the seal is decom-

pressed. Then adjust the gland, leaving a regular leaka-

ge-drip, which indicates proper lubrification.

The packed gland must be replaced when its sealing

properties have considerably decreased. A compres-

sed, hardened and dry packing causes the shaft to

wear.

8.3 Bearings lubrication

Up to frame size 160 the motors have prelubricated

bearings and they do not require any relubrication.

From frame size 180 the motors have grease nipples. A

relubrication at regular intervals (about 5000 h) is

recommended only in heavy working conditions, with

high ambient temperatures. An excess of grease is

harmful. Use lithium base grease for high temperatures.

8.4 Dismantling the system

Close the suction and delivery gate valves and drain

the pump casing before dismantling the pump.

8.5. Dismantling the pump

Close the suction and delivery gate valves and drain the

pump casing before dismantling the pump.

For dismantling and reassembly see construction in the

cross section drawing.

The motor and all internal parts can be dismantled

without removing the pump casing and pipes.

By removing the nuts (14.28) the motor can be taken

out complete with the impeller.

9. DISPOSAL

European Directive

2012/19/EU (WEEE)

The final disposal of the device must be done by spe-

cialized company.

Make sure the specialized company follows the

classification of the material parts for the separa-

tion.

Observe the local regulations and dispose the device

accordingly with the international rules for environ-

ment protection.

10 SPARE PARTS

10.1 Spare-parts request

When ordering spare parts, please quote their desi-

gnation, position number in the cross section drawing

and rated data from the pump name plate.

The spare parts request shall be sent to CALPEDA

S.p.A. by phone, fax, e-mail.

11 DESIGNATION OF PARTS

Nr. Designation

14.00Pump casing

14.04Plug (filling)

14.12Plug (draining)

14.20O-ring

14.24Screw

14.28Nut

28.00Impeller

28.04Impeller nut

28.12Circlip

28.20Impeller key

32.00Lantern bracket

32.30Guard

32.32Screw

32.33Caged Nut

34.00Casing cover

36.00Mechanical seal

36.50Shoulder ring

46.00Deflector

64.00Pump shaft

66.00Ball bearing, coupling side

66.18Circlip

70.18 Screw

70.19 Nut

73.00Pump-side bearing

76.00Motor casing with winding

76.04Cable gland

76.16Support

76.20Pin

76.54Terminal box, set

78.00Shaft with rotor packet

81.00Fan-side bearing

82.00Motor end shield, fan side

82.04Compensating spring

88.00Motor fan

90.00Fan cover

90.04Screw

92.00Tie-bolt

94.00Capacitor

94.02Capacitor gland

98.00Terminal box cover

98.04Screw

98.08Gasket

99.00Motor, complete

Changes reserved.

NM 40/20 - Operating Instructions

Page 7

Fig. 4 Draining.

IST NM 07_2018ed26_MXS 11_03con gall 19/06/18 09:03 Pagina 14

Loading...

Loading...