24

Section 4 Model 752 and 752A Differential Pressure Transmitters

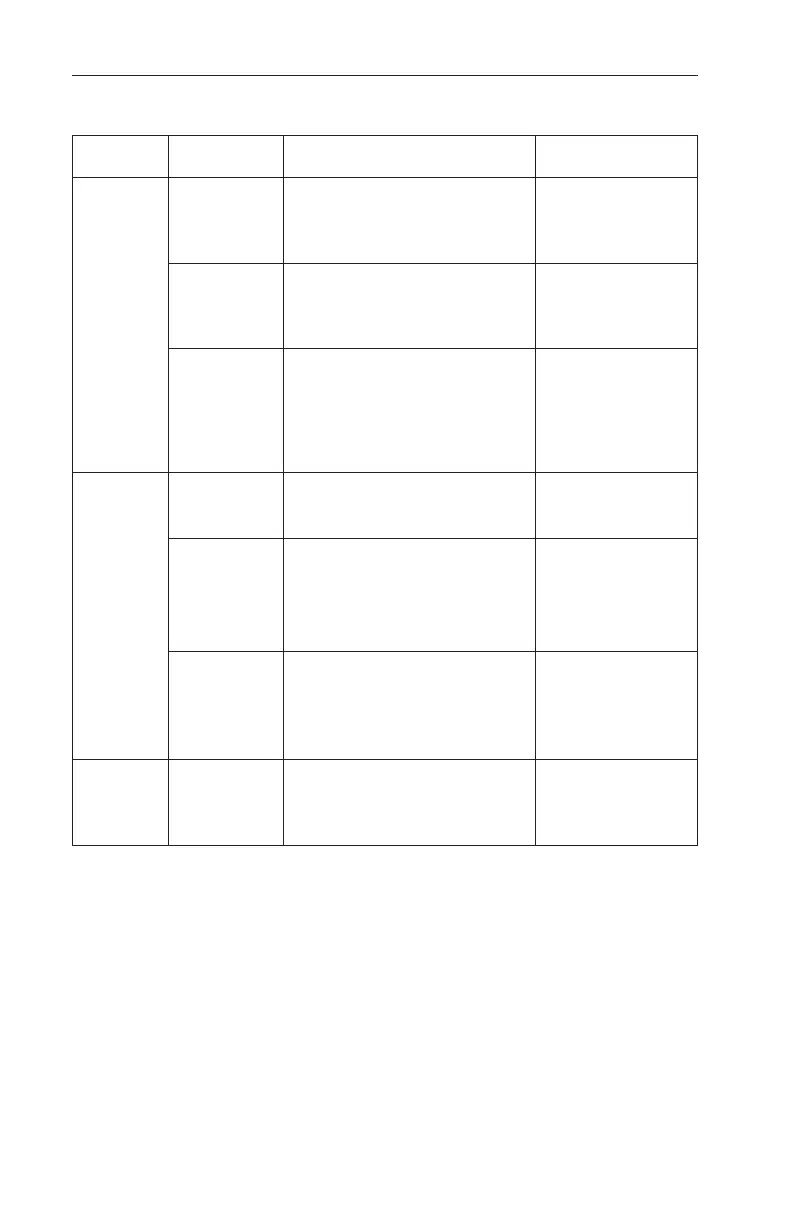

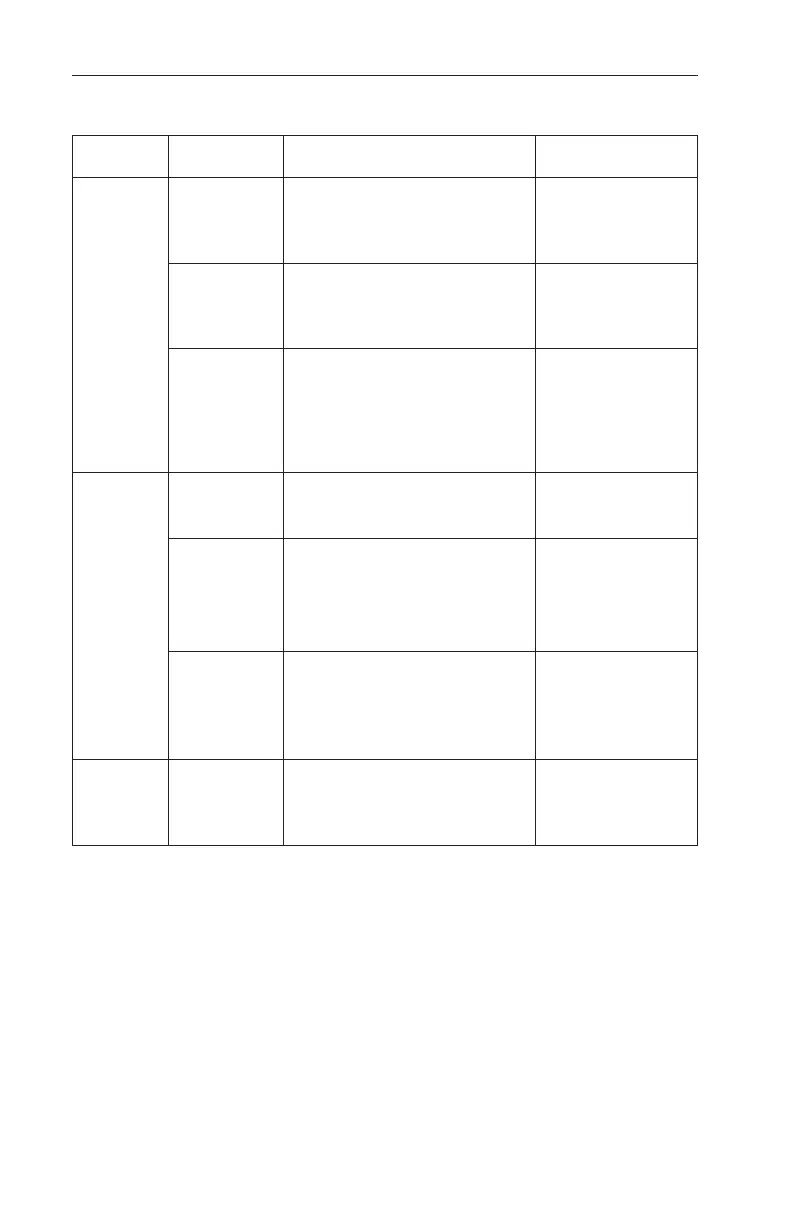

Table 4.3—DPU Troubleshooting

Problem Possible

Source

Probable Cause Corrective Action

High

Output

Primary

Element

Orice partially restricted or too

small;

Loss of liquid in reference leg

(liquid level)

Clean out or

replace;

Rell reference leg

Piping from

Primary

Element to

Transmitter

Leak in LP side piping Repair

Bellows Unit Gas trapped in LP housing in

liquid service or liquid trapped in

gas service;

LP housing gasket leaks;

Range spring broken or body

tampered with

Vent housing;

Replace gasket;

Return unit for

repair

Erratic or

Intermittent

Operation

Primary

Element

Flow pulsating Install dampening

device upstream of

meter run

Piping from

Primary

Element to

Transmitter

Liquid trapped in gas piping or

gas bubble in liquid piping;

Vapor generator installed wrong;

Reference leg gassy or liquid

vaporizing

Remove trapped

liquid or gas bubble;

Repipe;

See piping instruc-

tions

Bellows Unit Obstructed bellows travel;

Gas trapped in HP or LP housing

See DPU Inspec-

tion and Cleaning,

page 22.

Remove trapped

gas

Out of

Calibration

Bellows Unit Dirt in bellows;

Damaged bellows

Clean external

bellows surface or

return damaged

DPU for repair

Loading...

Loading...