20

Section 3 Model 764 Differential Pressure Transmitter

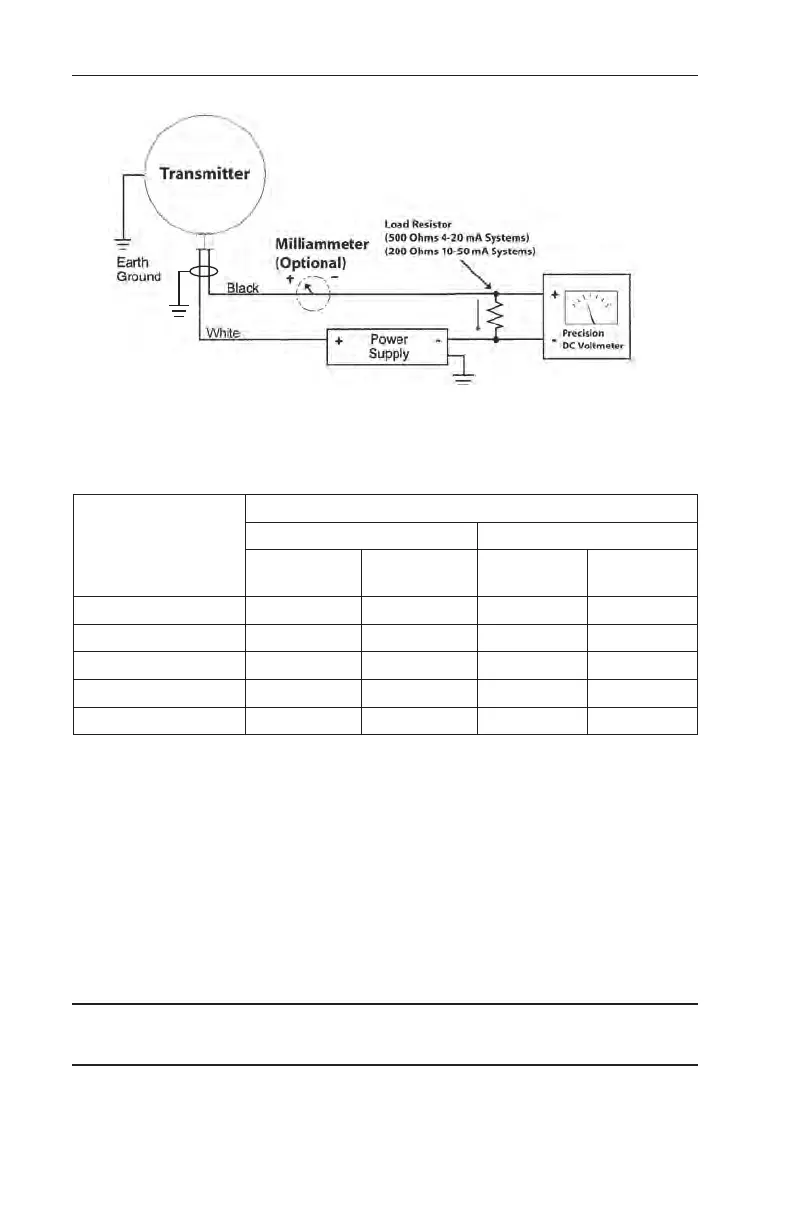

Figure 3.3—Electrical connections for calibration

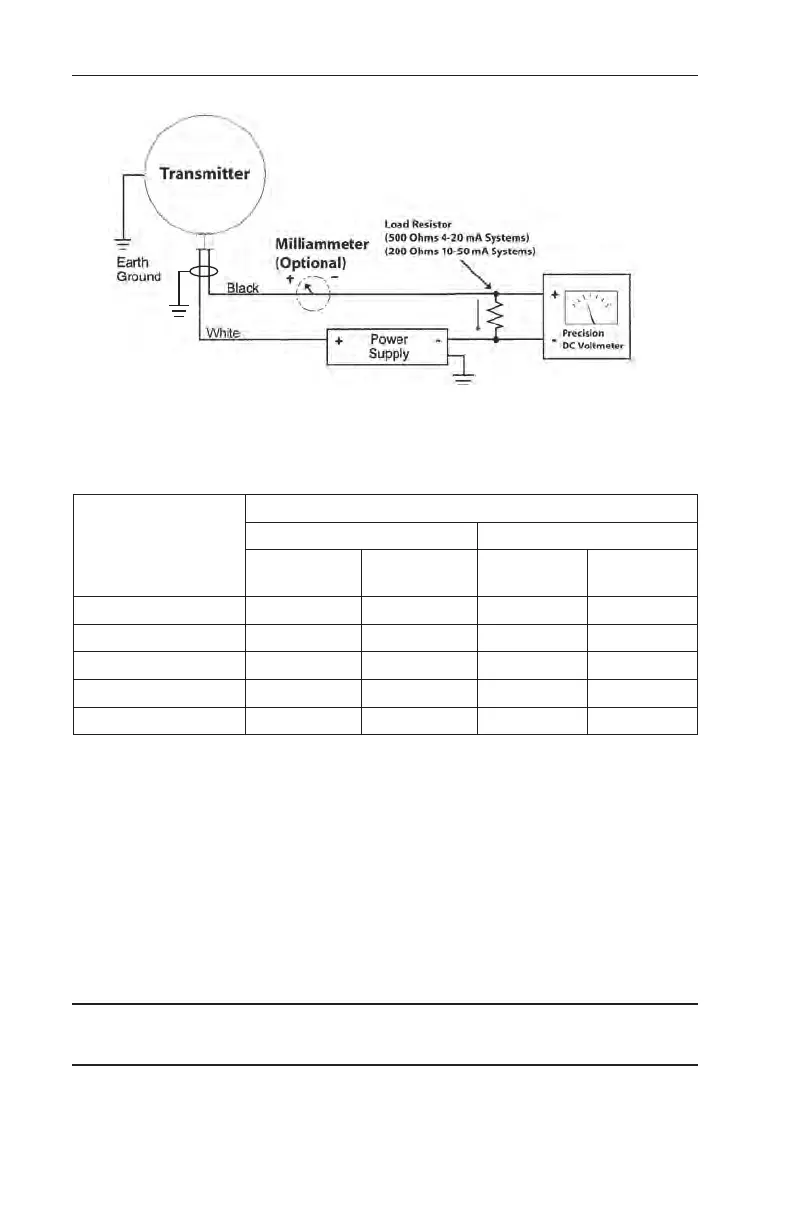

Table 3.1—Calibration Checkpoints

Applied Calibration

Pressure Check-

point (% of Full

Scale)

Output*

4-20 mA Transmitter** 10-50 mA Transmitter***

Current

(±0.08 mA)

Voltage

(±0.04 Vdc

Current

(±0.2 mA)

Voltage

(±0.04 Vdc)

0% 4 mA 2 Vdc 10 mA 2 Vdc

25% 8 mA 4 Vdc 20 mA 4 Vdc

50% 12 mA 6 Vdc 30 mA 6 Vdc

75% 16 mA 8 Vdc 40 mA 8 Vdc

100% 20 mA 10 Vdc 50 mA 10 Vdc

*This value includes the eects of conformance (non-linearity), deadband, hysteresis, and repeatability.

**This value was obtained using a 500-Ohm load resistor.

***This value was obtained using a 200-Ohm load resistor.

7. Replace the calibration access plugs as follows (or if the cover has no

calibration access plugs and was removed, see page 25 for instructions

on replacing the cover).

a. Replacement of the calibration plug O-rings is recommended (coat

with a small amount of silicone grease).

b. Install the calibration plugs.

c. Tighten the plugs until they are snug (no applicable torque values).

IMPORTANT: The plugs should be tightened only to prevent loosening due to vibration

without interfering with zero and span potentiometer adjustments.

Loading...

Loading...