Do you have a question about the Cameron ORBIT GP-19 and is the answer not in the manual?

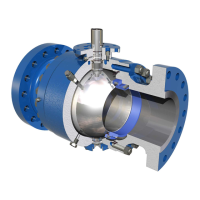

Check the valve nameplate for size, class, and trim.

Verify valve suitability for service by referring to service tag and nameplate.

Verify proper air supply or electric power source for valves with power actuators.

Verify all components and piping are undamaged for actuated valves.

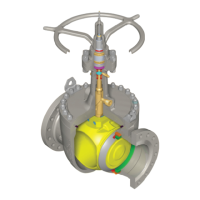

Orient valve so preferred pressure end faces higher pressure when closed.

Locate "Pref. Pres. End" stamping marked with red paint for easy identification.

Orient valve so preferred pressure end faces higher pressure when closed.

Locate "Pref. Pres. End" stamping marked with red paint for easy identification.

Connect the actuator power supply after the valve and actuator unit is installed.

Regulate supply pressure for pneumatic actuators to the amount shown on nameplate.

Connect opening air supply to point A and closing air supply to point B.

Check nameplate to determine if actuator is LG or LS type.

Do not install if nameplate is illegible; consult ORBIT Representative.

Connect closing air to point A and opening air to top of gas over oil tank (B).

Connect opening air supply to top of gas over oil tank (B) for spring close.

Connect opening air supply at A and closing air supply to gas over oil tank (B).

Connect opening air supply to point A for LS type spring close actuators.

Replace plug with filter breather on LS spring close actuators to prevent damage and injury.

Cycle valve fully open/closed, check indicator rod travel and instrumentation.

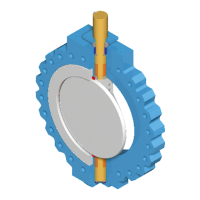

Explanation of model and standard trim codes used in figure numbers.

Table correlating valve size, ASME class, and nominal travel.

Identifies packing fitting, adjustment screw, and lube point on small bore standard valves.

Identifies lube point, adjustment bolts, and stem guide on small bore O.S.&Y. valves.

Identifies upper/lower lube points, packing fitting, adjustment screw, and stem guide.

Identifies upper lube point, stem guide, cover, and packing adjustment on large bore O.S.&Y. valves.

Recommends minimum lubrication frequency based on operation and service.

Consult representative for maintenance in special services like oxygen or HF acid.

Do not remove parts from pressure-containing areas unless instructed; danger exists.

Close valve to check fluid level for LG type; fluid should reach indicated level.

Open valve to check fluid level for LS type; fluid should reach fill plug level.

Warning against removing packing fitting due to potential injury and damage.

Advance or tighten the packing adjustment screw to stop stem leaks.

Warning against over-packing to prevent stiff operation or excessive pressure buildup.

Gently tap ball check with a pin punch to relieve excessive packing pressure.

Never remove hex nuts from gland retainer bolts while valve is under pressure.

| Brand | Cameron |

|---|---|

| Model | ORBIT GP-19 |

| Category | Control Unit |

| Language | English |