SIZE

CLASS

TRIM

2

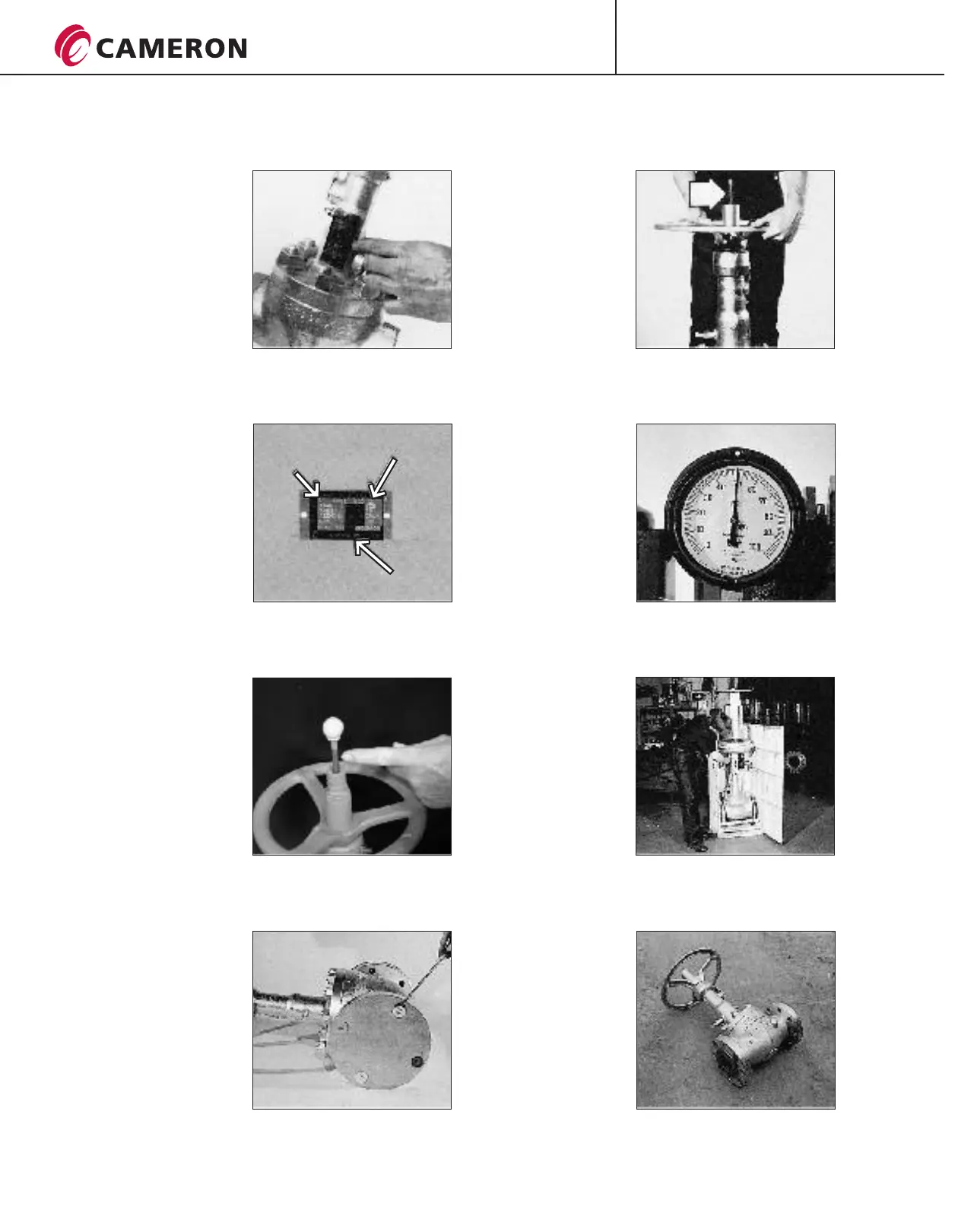

1 The first step is to

check the valve nameplate

for size, class and trim.

Size and class are also

marked on the body.

2 Verify that the valve is

suitable for the service in

which it is being installed

by referring to the service

tag and nameplate.

3 Check the handwheel

and position indicator rod

for possible damage.

4 On flanged valves,

remove the flange

protectors and inspect the

flange facings for deep

nicks and scratches.

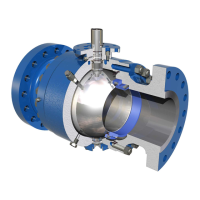

5 On handwheel valves,

cycle fully open and fully

closed to check for ease of

operation.

Check indicator rod travel

against dimensions on

page 8 to verify

full stem travel.

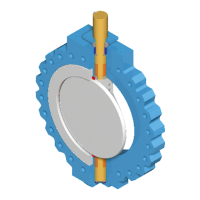

6 For valves equipped

with power actuators,

verify that a proper air

supply or electric power

source is available.

7 For actuated valves

equipped with an

instrument package,

verify that all components

and piping are undamaged.

8 After these points

have been checked and

approved, the valve is

ready for installation.

P R O C E S S V A L V E S

INSTALLATION, OPERATION AND MAINTENANCE

PRE-INSTALLATION INSPECTION

CT-ORB-IOM/6

05/08 ION-3M

®

ORBIT

Loading...

Loading...