1 - 1

1. MAINTENANCE

1.1 Adjustment, Periodic Maintenance, Periodic Replacement Parts, and

Replacement Consumables by Service Engineer

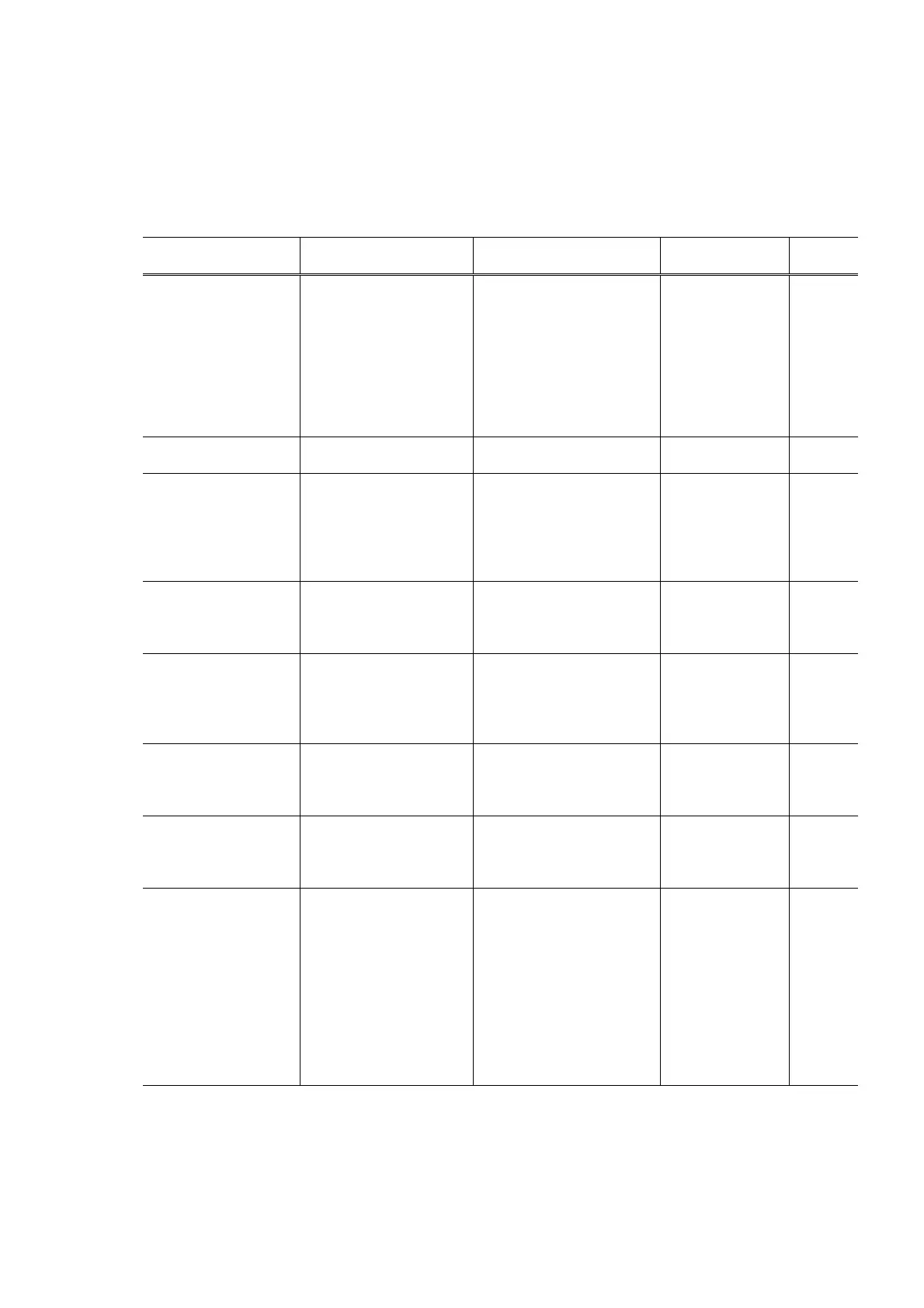

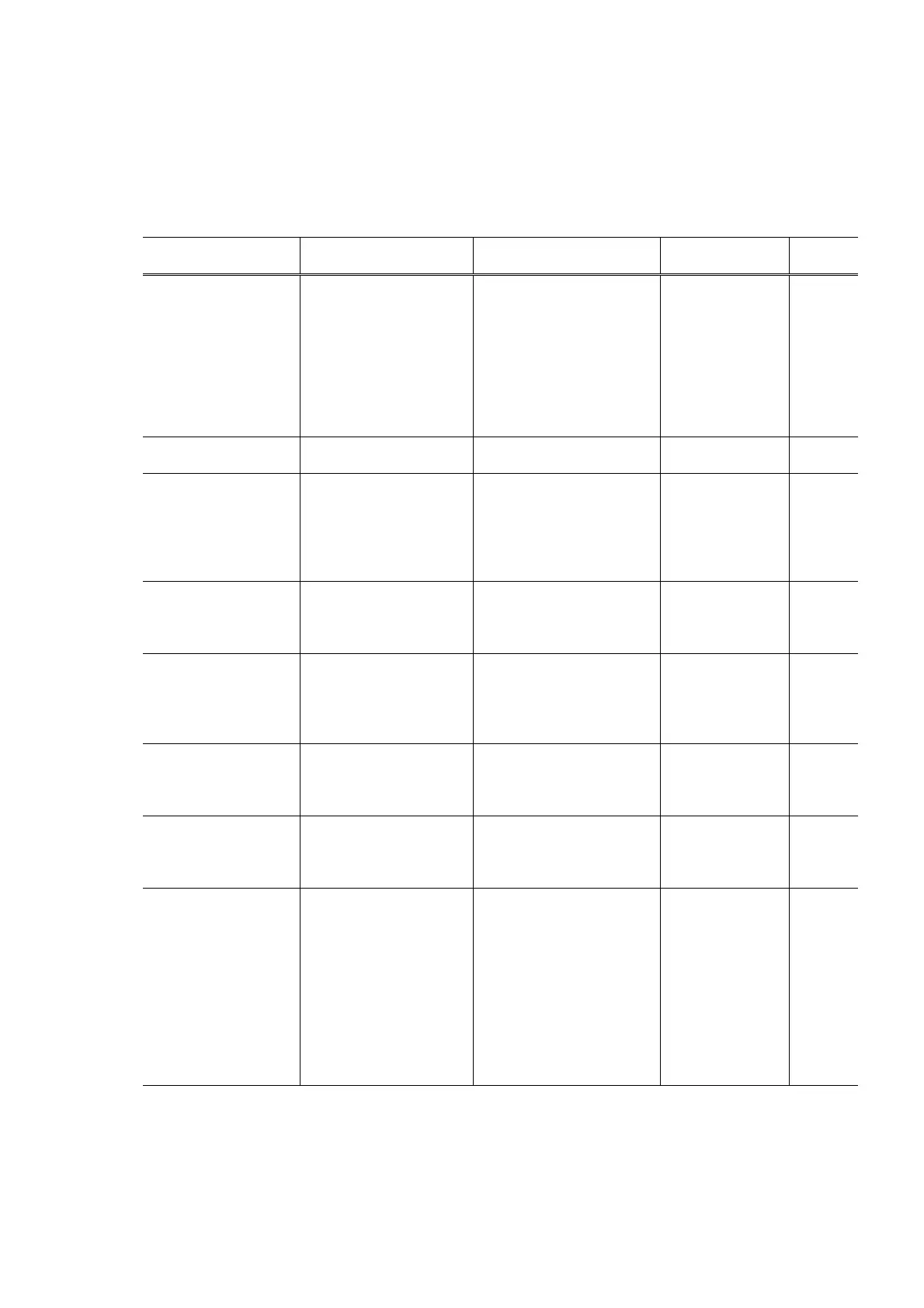

(1) Adjustment

Adjustment Timing Purpose Tool

Approx.

time

EEPROM

initialization

(EEPROM settings)

At logic board ass’y

replacement

To initialize settings other

than the following:

- USB serial number

- Destination setting

- On-arrival cleaning flag

- Waste ink counter

- Media sensor correction

value

- CD-R correction value

None. 1 min.

Destination settings

(EEPROM settings)

At logic board ass’y

replacement

To set the destination. None. 1 min.

Waste ink counter

resetting

- At bottom case unit

replacement

- At ink absorber

(QC1-2232 / 2233 /

2234 / 2235 / 2236)

replacement

To reset the waste ink

counter.

None. 1 min.

Media sensor

correction

*1

(EEPROM settings)

- At logic board ass’y

replacement

- At sheet feeder unit

replacement

To correct the media

sensor.

Calibration media

kit (QY9-0064)

*2

2 min.

CD-R sensor /

automatic print head

alignment sensor

correction

(EEPROM settings)

- At logic board ass’y

replacement

- At carriage unit

replacement

To correct the CD-R and

automatic print head

alignment sensor.

None.

(Correction

performed

through service

test print)

1 min.

Print head alignment - At print head

replacement

- At logic board ass’y

replacement

To ensure accurate dot

placement.

Computer

(settings via the

printer driver)

3 min.

Paper feed motor

position adjustment

*3

At paper feed motor unit

replacement

To adjust the belt tension.

(Position the paper feed

motor so that the belt is

stretched tight.)

None. 2 min.

Grease application - At carriage unit

replacement

- At paper guide flapper

ass’y (QL2-0341)

replacement

- At lift cam base’s

(QL2-0340) gear

replacement

- At lift cam shaft unit

(QM2-0593)

replacement

- To maintain sliding

properties of the carriage,

carriage shaft, paper

guide flapper, and lift

cam shaft.

- To protect the lift cam

base gear.

- To maintain sliding

properties of the lift cam

shaft.

- FLOIL

KG-107A

(QY9-0057)

- MOLYKOTE

PG641

(CK-0562)

- EU-1

(QY9-0037)

2 min.

Note: DO NOT loosen the red screws on both sides of the main chassis, securing the carriage shaft positioning.

*1: Media sensor correction

This operation adjusts the correction value of the media sensor, installed in the sheet feeder unit, to the

EEPROM of the logic board ass’y. The adjustment is required when the sheet feeder unit or the logic board

ass’y is replaced, and values are automatically determined via use of calibration media kit (QY9-0064).

*2: Calibration media kit

The service tool for media sensor correction, consisting of 10 sheets of the reference plain paper, and 1

Loading...

Loading...