1 - 2

sheet of the reference white PET paper.

*3: Red screws of paper feed motor

The red screws securing the paper feed motor may be loosened only at replacement of the paper feed motor

unit.

(2) Periodic maintenance

No periodic maintenance is necessary.

(3) Periodic replacement parts

There are no parts in this printer that require periodic replacement by a service engineer.

(4) Replacement consumables

There are no consumables that require replacement by a service engineer.

1.2 Customer Maintenance

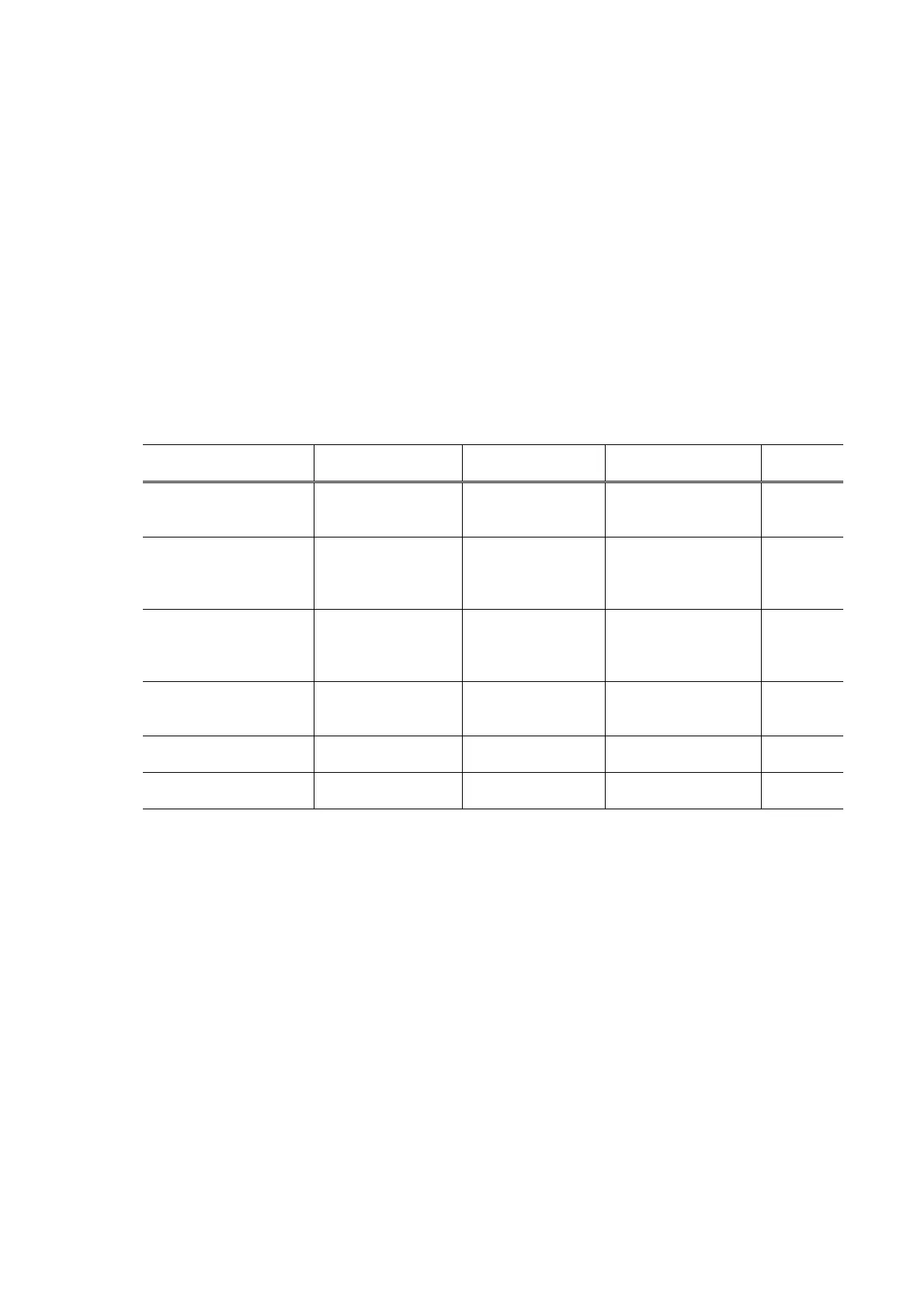

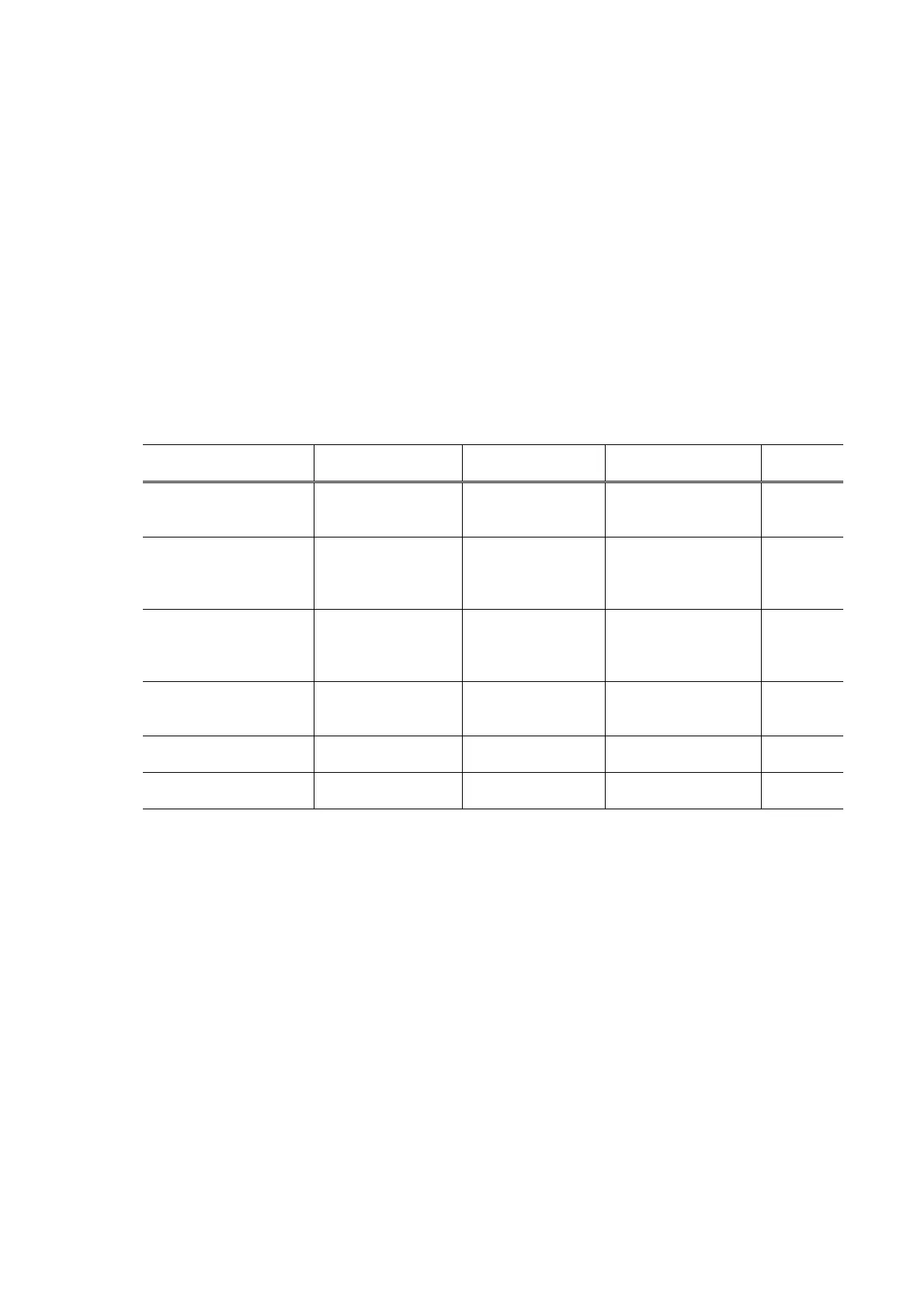

Adjustment Timing Purpose Tool

Approx.

time

Print head alignment At print head

replacement.

To ensure accurate

dot placement.

Computer (Automatic

settings via the printer

driver)

5 min.

Print head cleaning When print quality is

not satisfying.

To improve nozzle

conditions.

- Printer buttons

- Computer (settings

via the printer

driver)

30 sec. to

1 min.

Print head deep cleaning When print quality is

not satisfying, and

not improved by

print head cleaning.

To improve nozzle

conditions.

Computer (settings

via the printer driver)

1 to 1.5

min.

Ink tank replacement When an ink tank

becomes empty.

(No ink error)

----- -----

2 min.

Paper feed roller

cleaning

When paper does not

feed properly.

To clean the paper

feed rollers.

Printer buttons 2 min.

CD-R print position

adjustment

At CD-R printing,

when necessary

To correct CD-R

print position

Computer (application

software)

5 min.

1.3 Product Life

(1) Printer

The value from (i) to (iv), whatever comes first.

(i) 10,000 pages of color printing

- Color: 7.5% duty per color pattern printing, A4

(ii) 1,200 disks of CD-R or DVD-R printing

- On a basis of monthly print volume of approx. 20 disks

(iii) 5,000 pages of printing using the photo paper tray

- On a basis of monthly print volume of approx. 83 pages

(iv) 5 years of use

Loading...

Loading...