Code +030220811- rel. 1.0 – 26.04.2007

8

2.2 In-line filter

Always install a mechanical filter before the refrigerant inlet, with both welded valves (E2V***S***) and valves with

threaded fittings (E2V***RB**). For the latter, a filter is supplied inside the packaging that can be placed directly in

the valve inlet pipe.

If the installation is bi-directional (flow of refrigerant in both directions, reverse-cycle heat pumps), a bi-directional

liquid/gas filter should be fitted on both expansion valve connections, or other solutions can be used, depending on

the layout of the installation.

2.3

Flow of refrigerant and spatial orientation of the valve

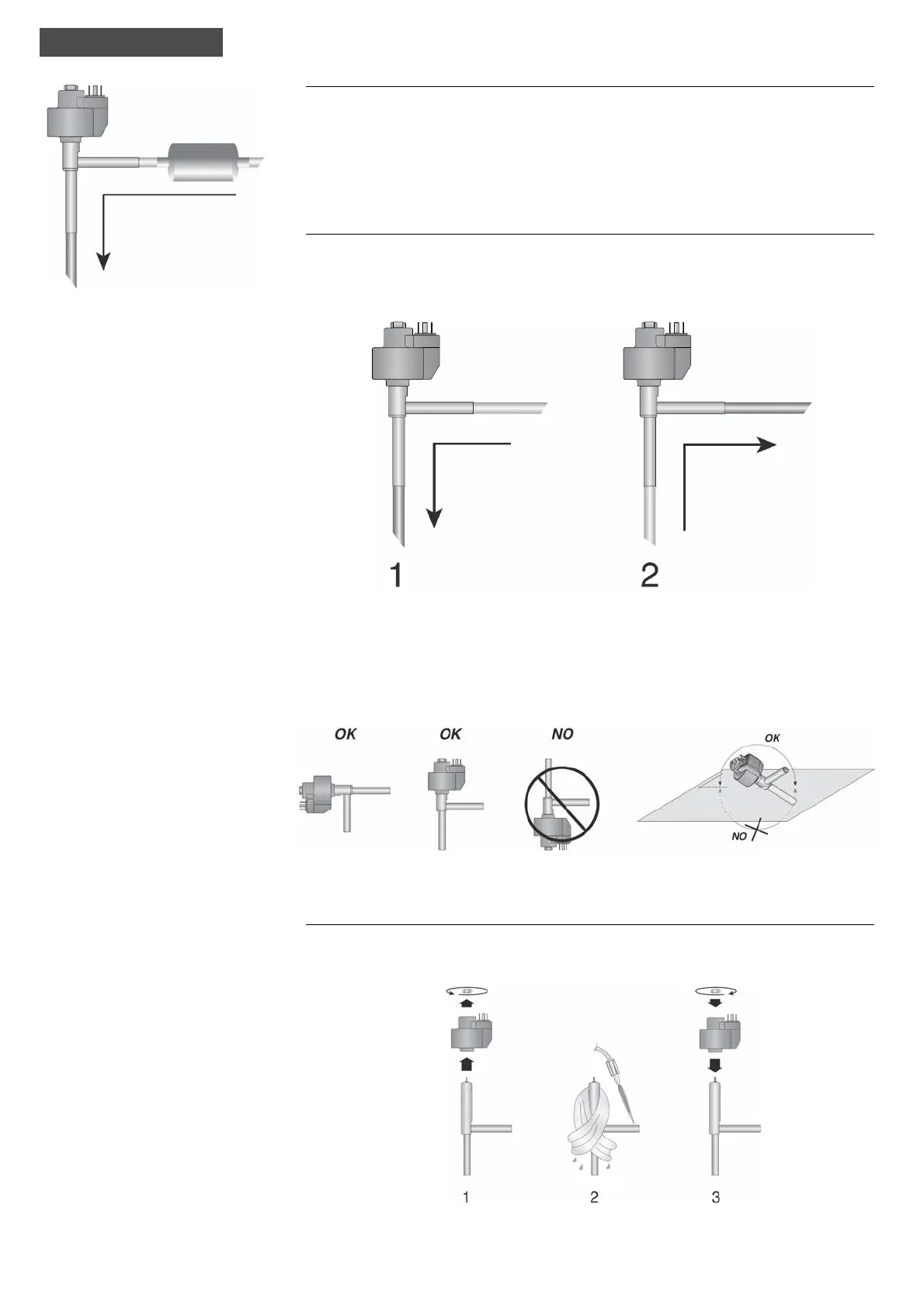

The recommended direction of connection (Figure 2.c) sees the inlet on the side of the valve; nonetheless, the

CAREL E

2

V valves are bi-directional up to the pressure differential specified on the instruction sheet.

Important: in no circumstances is upside-down installation allowed, that is, with the stator facing downwards.

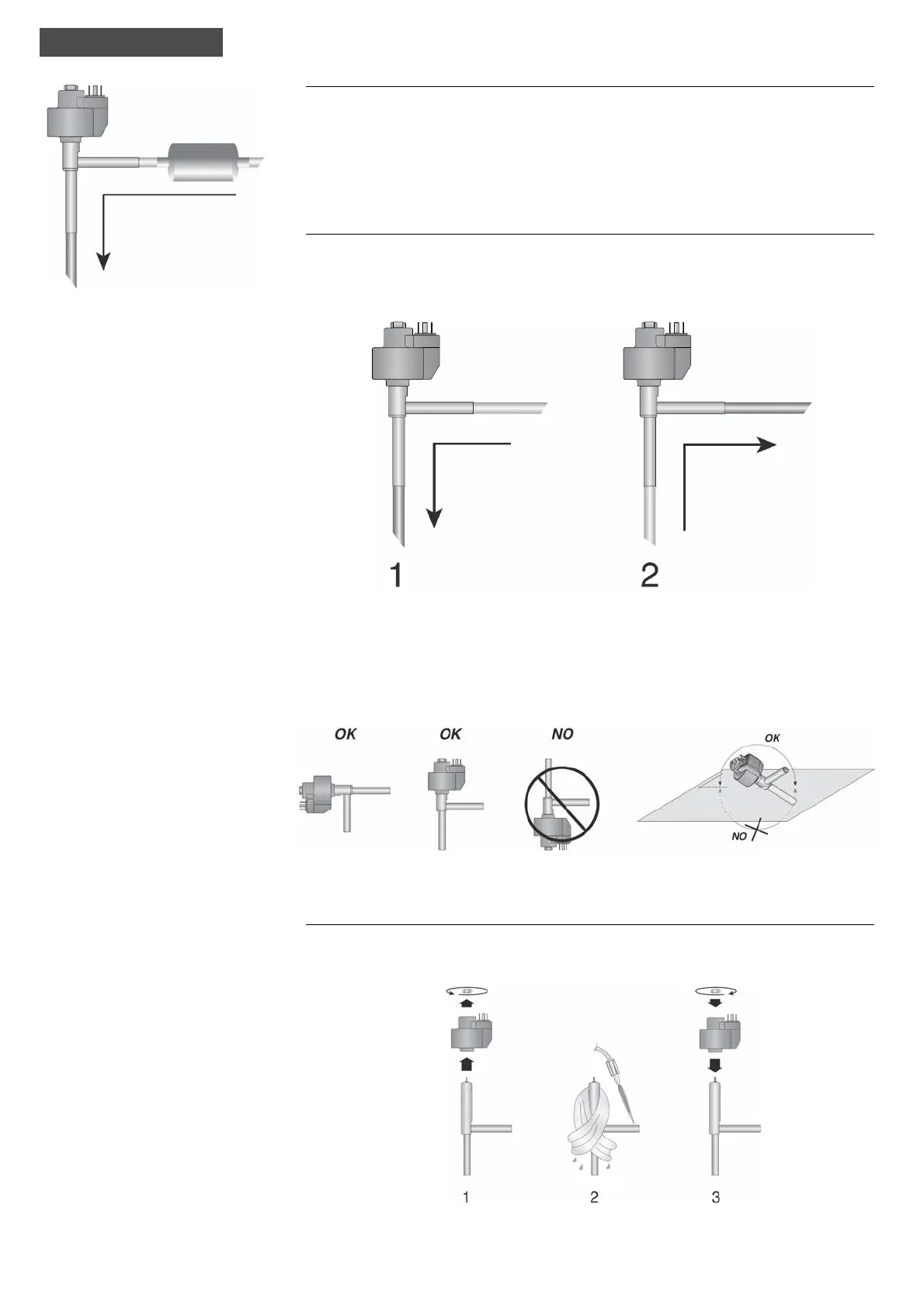

2.4 Welding

Unscrew the locking nut and remove the stator (winding). If necessary, remove the connector if inserted. Before

starting welding, wrap the body of the valve (without the stator)

in a wet rag, to avoid overheating the inside parts.

When finished welding, replace the stator

and tighten the valve-stator locking nut.

Fig. 2.c

Fig. 2.d

Recommended

direction

Fig. 2.e

Fig. 2.f

installation

Loading...

Loading...