µRack

Cod. CAREL +03P220431 rel. 2.2 dated 10/02/12

31

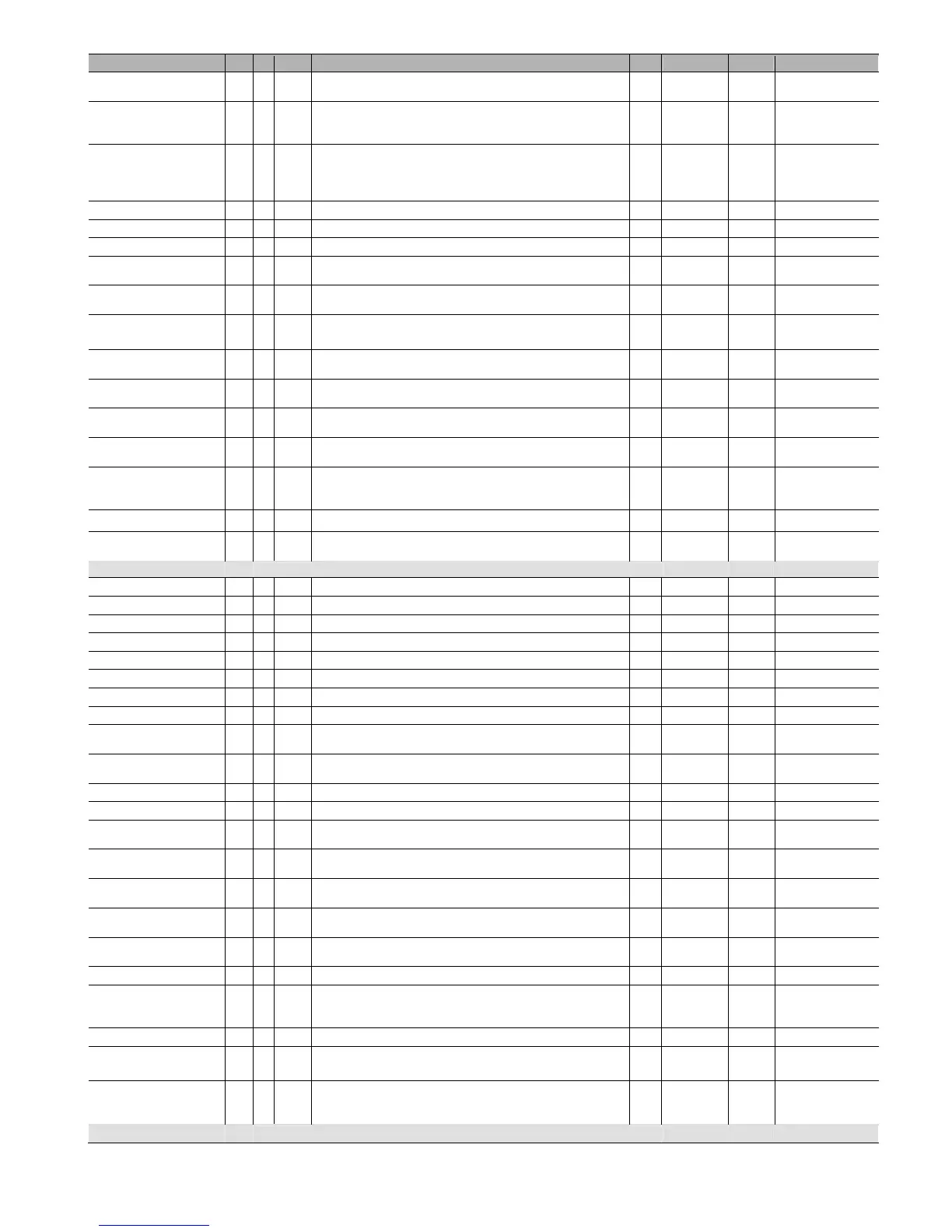

Parameter Type Pos. Display Description UOM Range Default Notes

Fan inverter differential R/W U r19 Fan inverter differential

bar

°C

0 to 20.0

0 to 20.0

3

18

Only if the inverter if

enabled

Fan rotation R/W C r20

Type of fan rotation.

0) NO ROTATION

1) FIFO

0/1 1 For single circuit only

Fan control R/W C r21

Type of fan control:

0) Proportional

1) Proportional + integral

2) Dead band

0 to 2 0 For single circuit only

Integral time (P+I only) R/W C r22 Integral time with P+I control s 0 to 999 600 Only if PI

Time between fan start call R/W C r23 Minimum time between two successive calls to start different fans s 0 to 999 2 xx

Time between fan stop call R/W C r24 Minimum time between two successive calls to stop different fans s 0 to 999 2 xx

Min fan set point R/W C r25 Set the lower limit of the fan set point

bar

°C

0 to r26

-50 to r26

1.0

-31.2

Max fan set point R/W C r26 Set the upper limit of the fan set point

bar

°C

r25 to 40.0

r25 to 150

25.0

55.3

Fan inverter speedup time R/W C r27 Fan inverter speedup time s 0 to 999 2

Only if the inverter is

enabled

Inverter ramp up time R/W I r28 Set the time taken by the inverter to reach full load s 0 to 999 10

Only if the inverter is

enabled

Minimum fan inverter output R/W C r29 Set the minimum operation of the fan inverter % 0 to r30 0

Only if the inverter is

enabled

Maximum fan inverter output R/W C r30 Set the maximum operation of the fan inverter % r29 to 100 100

Only if the inverter is

enabled

Triac impulse duration R/W C r31 Duration of the impulse applied to the triac ms 0 to 10 0

Only if the inverter is

enabled

Enable floating condenser

control

R/W C r32

Enable the floating condenser control

0) NO

1) YES

0 to 1 0

Condensing Delta T R/W C r33 Temperature difference for floating condenser control -40 to 150 10

Compressor management

offset set point

R/W I r34

Compressor bar auxiliary set point offset.

Used when changing the set point from digital input

-99.9 to 99.9 0

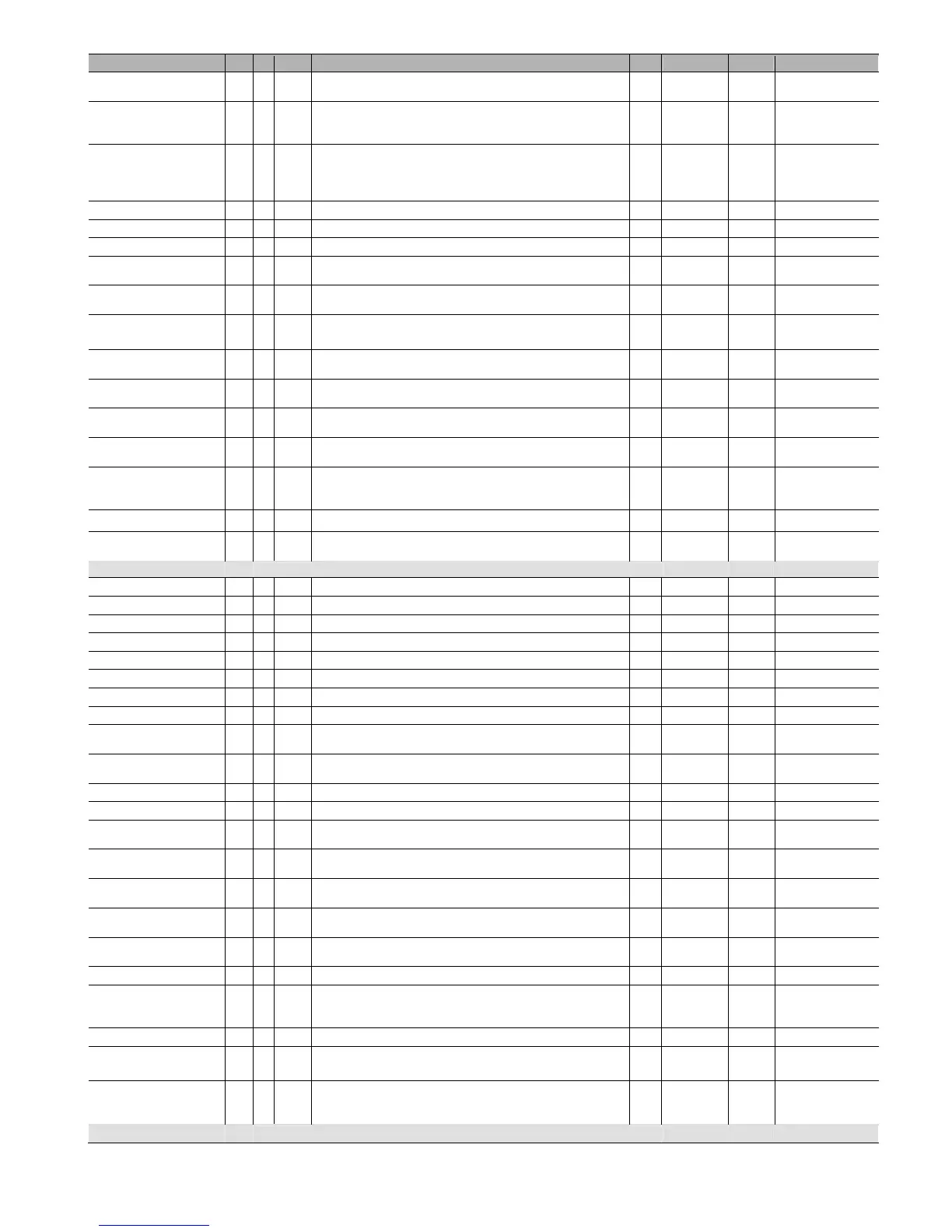

Alarm menu

HP suction 1 alarm R/W I A01 Suction probe 1 alarm: high threshold setting bar A03 to /19 9.3

HP suction 1 delay R/W I A02 Suction probe 1 alarm: delay setting s 0 to 999 60

LP suction 1 alarm R/W I A03 Suction probe 1 alarm: low threshold setting bar /17 to A01 0

LP suction 1 delay R/W I A04 Suction probe alarm: delay setting s 0 to 999 60

HP suction 2 alarm R/W I A05 Suction probe 2 alarm: high threshold setting bar A07… /20 20 For two circuits only

HP suction 2 delay R/W I A06 Suction probe 2 alarm: delay setting s 0 to 999 60

LP suction 2 alarm R/W I A07 Suction probe 2 alarm: low threshold setting bar /18 to A05 0 For two circuits only

LP suction 2 delay R/W I A08 Suction probe alarm: delay setting s 0 to 999 60

HP discharge alarm R/W I A09 Discharge probe alarm: high threshold setting

bar

°C

A10 to /20

A10 to 150

20.0

45.8

LP discharge alarm R/W I A10 Discharge probe alarm: low threshold setting

bar

°C

/18 to A09

-50 to A09

0

-50

Discharge delay R/W I A11 Discharge probe alarm: delay setting s 0 to 999 60

Compressor thermal delay R/W I A12 Compressor thermal overload alarm: delay setting s 0 to 999 0

HP prevention

Prevent time 1

R/W I A13 Time in which start calls are ignored after prevent HP m 0 to 99 5

Only if the prevent is

enabled

HP prevention

Prevent time 2

R/W I A14

If two prevent alarms occur within this time, an excessive prevent frequency

alarm is generated

m 0 to 999 6

Only if the prevent is

enabled

HP prevention

Prevent time 3

R/W I A15

If no prevent alarms occur in this period, the high prevent frequency alarm is

automatically reset

m 0 to 99 30

Only if the prevent is

enabled

High temp. probe threshold:

B2

R/W I A16 High temperature threshold, probe B2 °C -40 to 150 100

High temp. probe threshold:

B3

R/W I A17 High temperature threshold, probe B3 °C -40 to 150 100

Delay liquid level alarm R/W I A18 Set the liquid level alarm delay from multifunction input m 0 to 500 60

Reset ALARMS R/W U A19

Reset the alarms with manual reset

0) NO RESET

1) RESET

0/1 0

Alarm signal delay R/W I A20 Set alarm signal delay s 0 to 999 1

Exchange auto->man LP 3

alarms

R/W I A21

On the 3rd activation, within the set time, the low pressure alarm from

pressure switch changes from automatic to manual reset.

m 0 to 999 10

OFF due to probe

disconnected

R/W I A22

Enable unit OFF due to probe disconnected/alarm

0) NO

1) YES

0/1 0

Maintenance menu

Loading...

Loading...