lb-00193-14.EN Pag. 15 10-02-09

2. Turbine alarm.

Cause: the volume meter is not sending signals to the control unit within a time-out of 5 seconds.

Result: delivery continues up to a time-out of 240 seconds or until the selected key is pressed, and all the LEDs on the push-button

panels flash (medial flashes)

Solution: carry out the following controls.

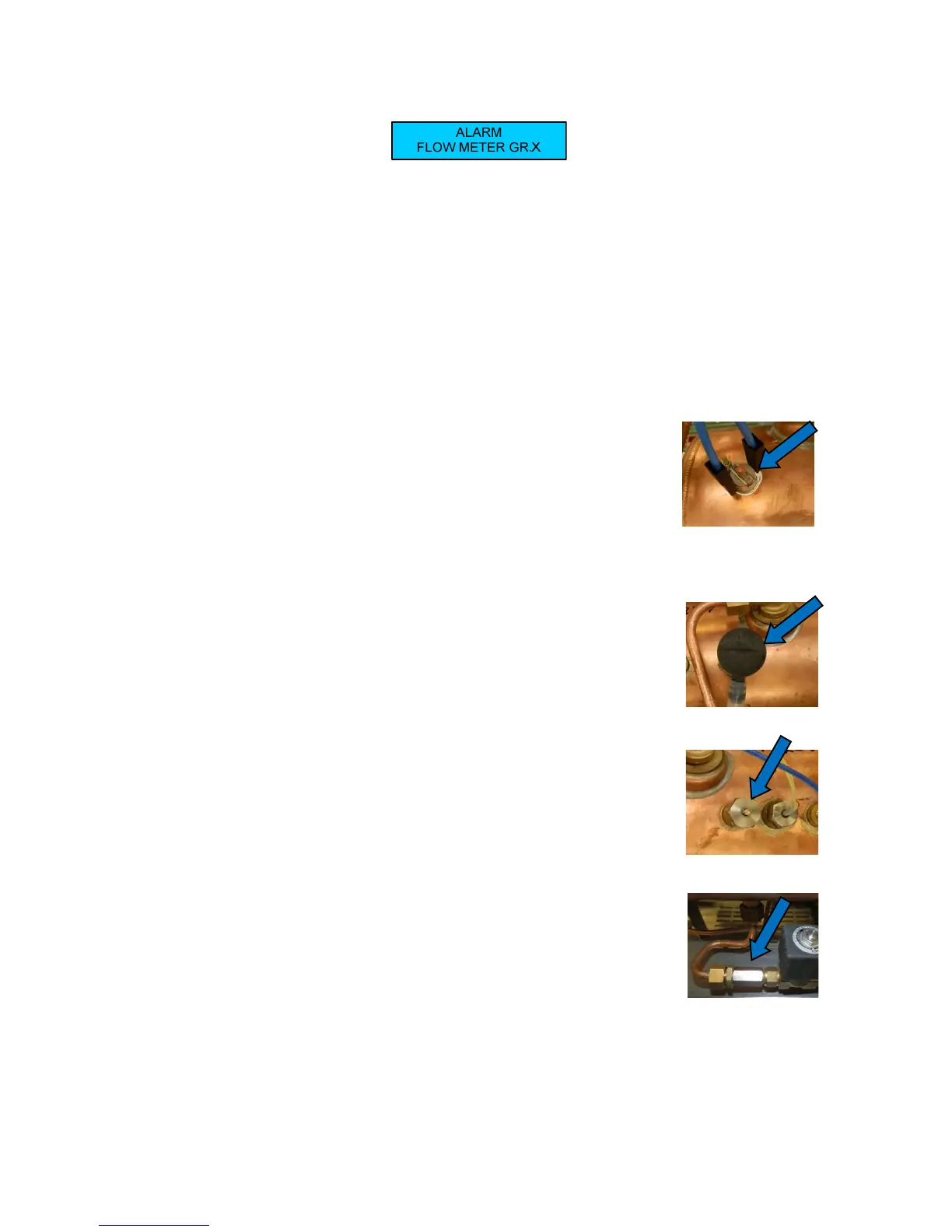

• No water from mains (coffee is not dispensed)

• clogged group piston filters (coffee is not dispensed)

• faulty group solenoid valve (coffee is not dispensed)

• clogged entrance filters (coffee is not dispensed)

• blocked or faulty volume meter (coffee dispensed continuously)

• faulty electrical connection (coffee dispensed continuously).

If the coffee is dispensed continuously, use the machine as if it were manual: press the required key to start up the dose, then press the

same key to stop the dose being dispensed, after checking the amount in the cup.

3. Safety Klixon operation.

Cause: The temperature of the boiler has reached the limit of 145°C.

Result: the heating is interrupted.

Solution: carry out the following controls.

• Level probe (SLC) earthed

• Faulty temperature probe

• Faulty Triac

• Defective inlet solenoid valve

WARNING: To activate the safety Klixon, it is necessary to press the button placed at the centre of the thermostat itself.

4. Safety valve operation.

Cause: overpressure in steam boiler

Result: the 1.7-1.9 bar safety valve opens and releases steam in the upper part of the machine.

Solution: carry out the following controls:

• Triac earthed

• Faulty temperature probe

5. Anti-vacuum valve.

The anti-vacuum valve is installed on the boiler and prevents any air remaining during

the loading phase and a depression being created during the heating phase.

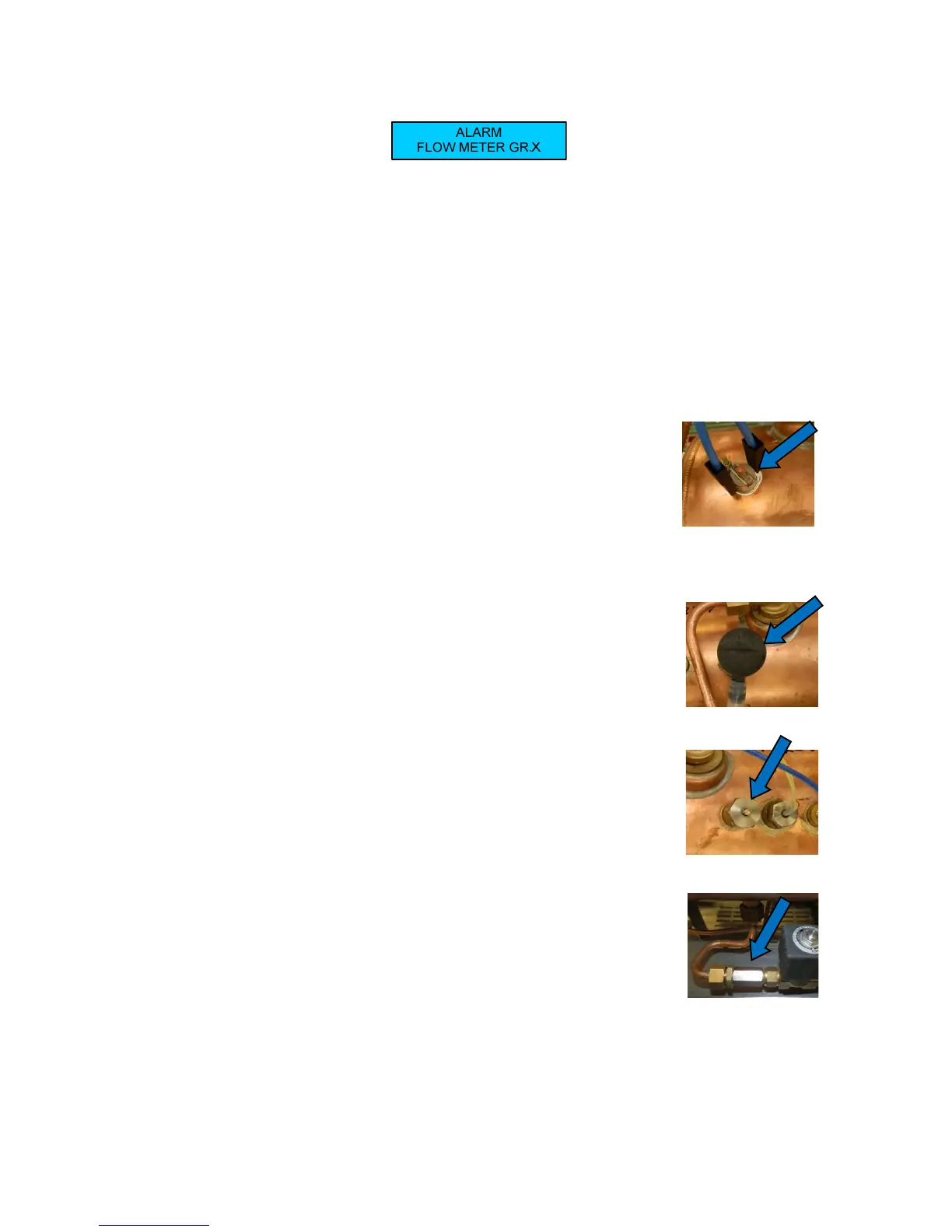

6. Non-return valve.

The non-return valve is installed between the loading solenoid valve and the boiler

and has the following function:

During the loading phase it opens by means of the water pressure, letting the water enter

into the boiler. Once the loading phase is over, it closes preventing the water in the

steam boiler from returning to the water supply network.

Loading...

Loading...