6 Specications are subject to change without notice. Pictures are just an example. For special features and/or customization, please ask to our sales network. 18/11/2014

Motor Controllers AC Variable Frequency Drives Type Variex

3

RVLF

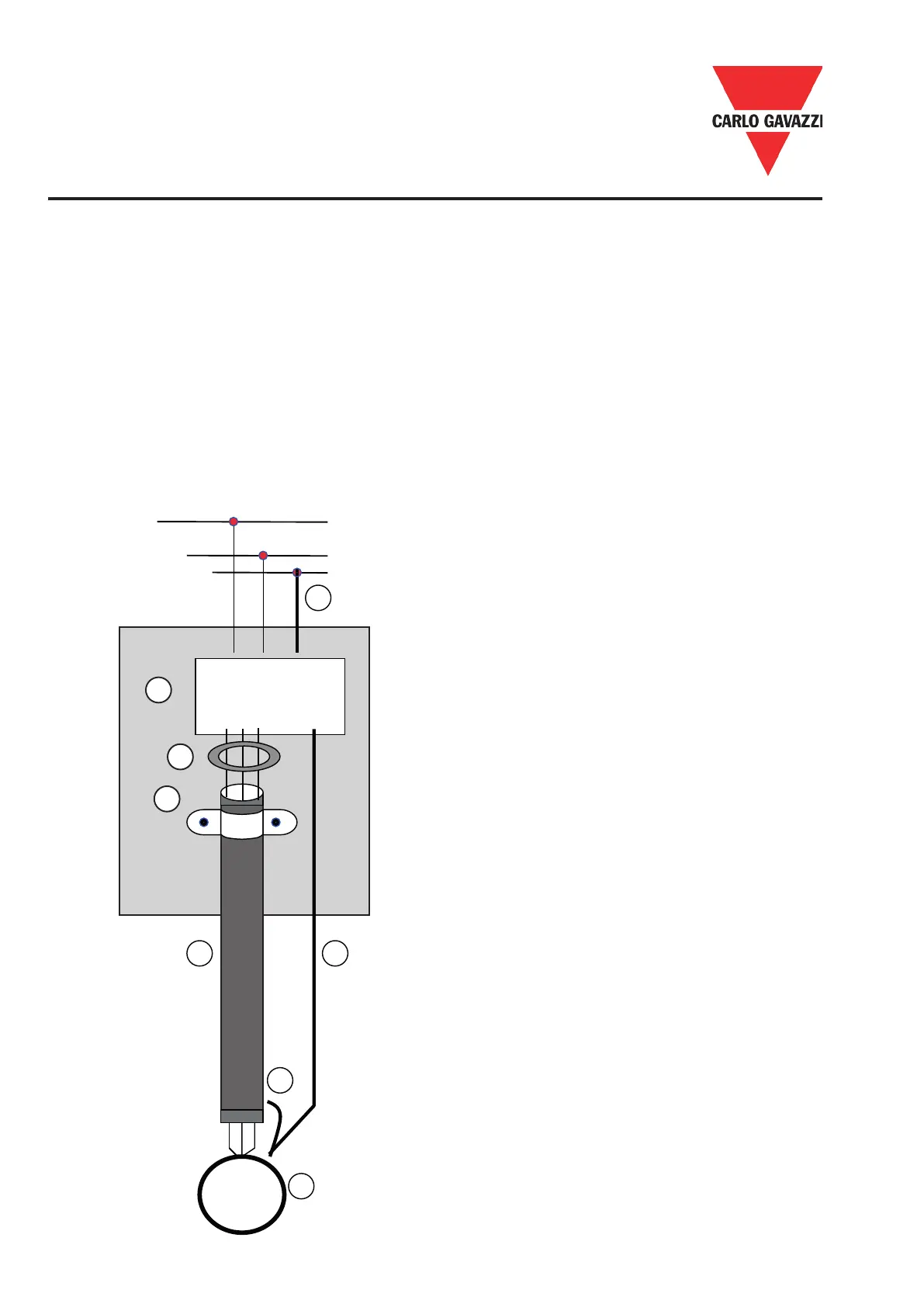

3.1. Wiring and EMC Guidelines

For effective interference suppression, do not route power and control cables in the same

conduit or trucking. To prevent radiated noise, motor cable should be put in a metal conduit.

Alternatively an armored or shielded type motor cable should be used.

For effective suppression of noise emissions the cable armor or shield must be grounded at

both ends to the motor and the inverter ground. These connections should be as short as

possible. Motor cable and signal lines of other control equipment should be at the least 30 cm

apart.

RVLF has a built in Class “A” EMC lter to rst environment restricted. (Category C2).

For some installations such as residential, (Category C1) an optional external Class “B” type

lter will be necessary. Please consult your local supplier.

1. Protective earth conductor.

Conductor size for enclosure & back plate

must comply with the local electrical

standards. Min 10mm².

2. Back plate. Galvanised steel (Unpainted).

3. Ferrite core/Output reactor ferrite cores can

be used to reduce radiated noise due to long

motor cables. If ferrite core is used loop motor

wires, 3 times round the core. Install core as

close to the inverter as possible.

Output reactors provide additional benet of

reducing dv/dt for protection of motor windings.

4. Metal cable clamp. no more than 150mm

from the inverter.

Note: If no enclosure & back plate is used

then connect the cable shield by a good 360º

termination to the Inverter output terminal E.

5. Screened (shielded four core cable).

6. Separate protective earth wire, routed outside

motor cable separated be at least 100mm.

Note: this is the preferred method specially for

large output cables and long length. Multi core

screened (3 core & protective earth) can be

used for small power and short length.

7. Connect the cable shield by a good 360º

termination and connect to the motor

protective earth terminal. This link must be as

short as possible.

8. Motor earth terminal (protective earth).

L1 (L)

L1 (L) L3 (N)

Drive

E

E

T1 T2 T3

L3 (N)

E

2

1

3

4

5

6

7

8

PE

M

Typical Wiring.

3. Environment & Installation

Loading...

Loading...