14

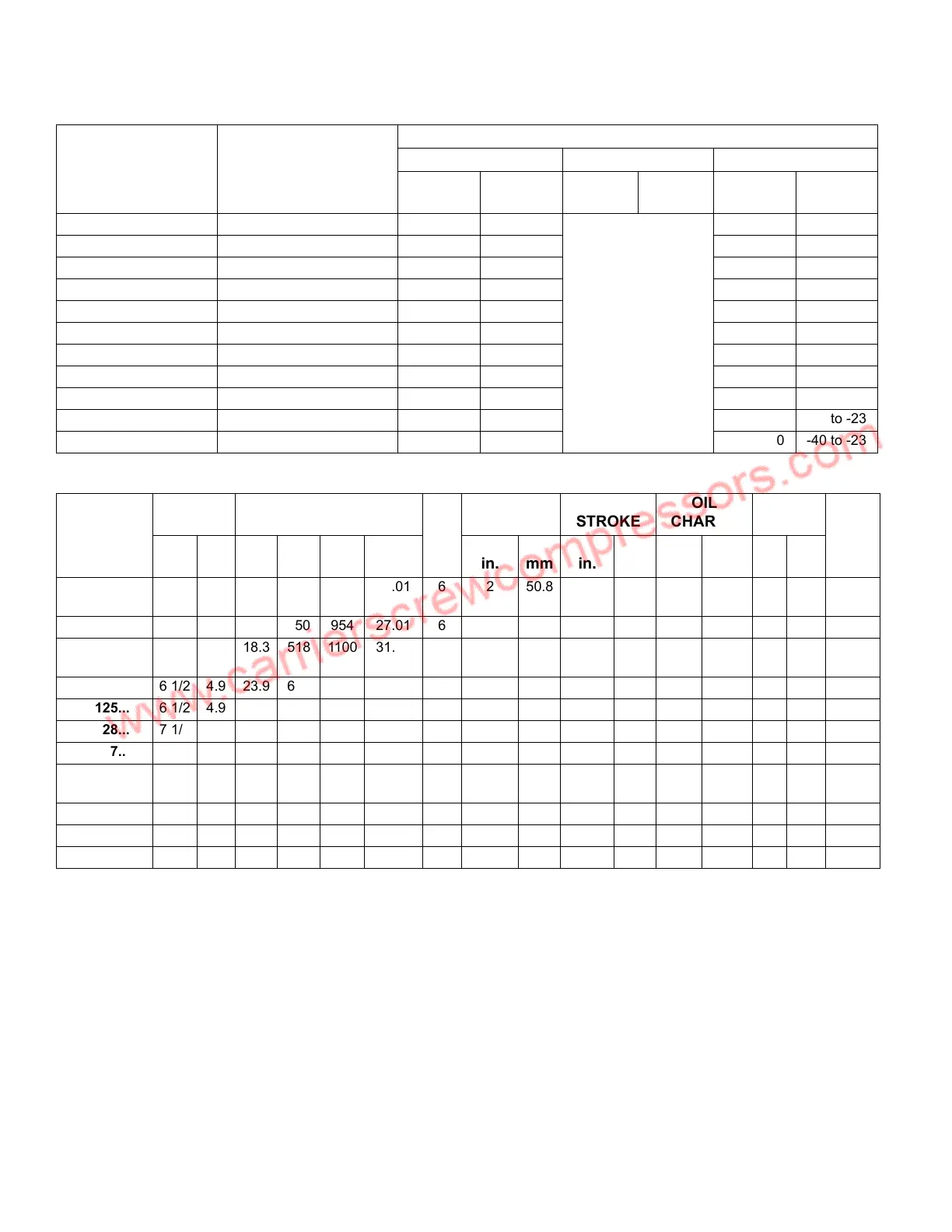

1.2 Physical Data

LEGEND

NOTES:

1. Approximate condensing temperature ranges. CHECK ACTUAL

PERFORMANCE DATA FOR ANY NEW APPLICATION ESPE-

CIALLY AT OR NEAR UPPER OR LOWER LIMIT: L.T. =70 to 130 F

(21 to 55 C).

2. To provide a 6-cylinder body needed for Carlyle

®

Compound Cooling

compressor, the normal 4-cycle model 16, 18 and 50 cfm compres-

sors were built using the 24 and 65 cfm 6-cylinder bodies, respec-

tively. The actual cfm reduction is achieved by modifying the running

gear.

3. R404A/R-507 CANNOT be used in the small “D” body size Com-

pound Cooling compressors (16 to 37 cfm), manufactured prior to

SerIal No. 2099J. See Section 1.5.

4. R-134a and R-12 CANNOT be used in any Compound Cooling

compressor.

CARRIER /

CARLYLE MODEL

NUMBER

STANDARD SERVICE

REPLACEMENT

MODEL

SUCTION TEMPERATURE RANGE ...(See Note 1)

R-404A/R-507 R-134a R-22 and R-407A

F (See

Note 3)

C (See

Note 3)

F C F C

06CC016...(See Note 2) 06CY016... -40 to -10 -40 to -23 (See Note 4) -40 to -10 -40 to -23

06CC017... 06CY017... -40 to -10 -40 to -23 -40 to -10 -40 to -23

06CC018...(See Note 2) 06CY018... -40 to -10 -40 to -23 -40 to -10 -40 to -23

06CC124... 06CY124... -60 to -10 -51 to -23 -40 to -10 -40 to -23

06CC125... 06CY125... -60 to -10 -51 to -23 -40 to -10 -40 to -23

06CC228... 06CY228... -60 to -10 -51 to -23 -40 to -10 -40 to -23

06CC337... 06CY337... -60 to -10 -51 to -23 -40 to -10 -40 to -23

06CC550...(See Note 2) 06CY550... -40 to -10 -40 to -23 -40 to -10 -40 to -23

06CC665... 06CY665... -60 to -10 -51 to -23 -40 to -10 -40 to -23

06CC675... 06CY675... -60 to -10 -51 to -23 -40 to -10 -40 to -23

06CC899... 06CY899... -60 to -10 -51 to -23 -40 to -10 -40 to -23

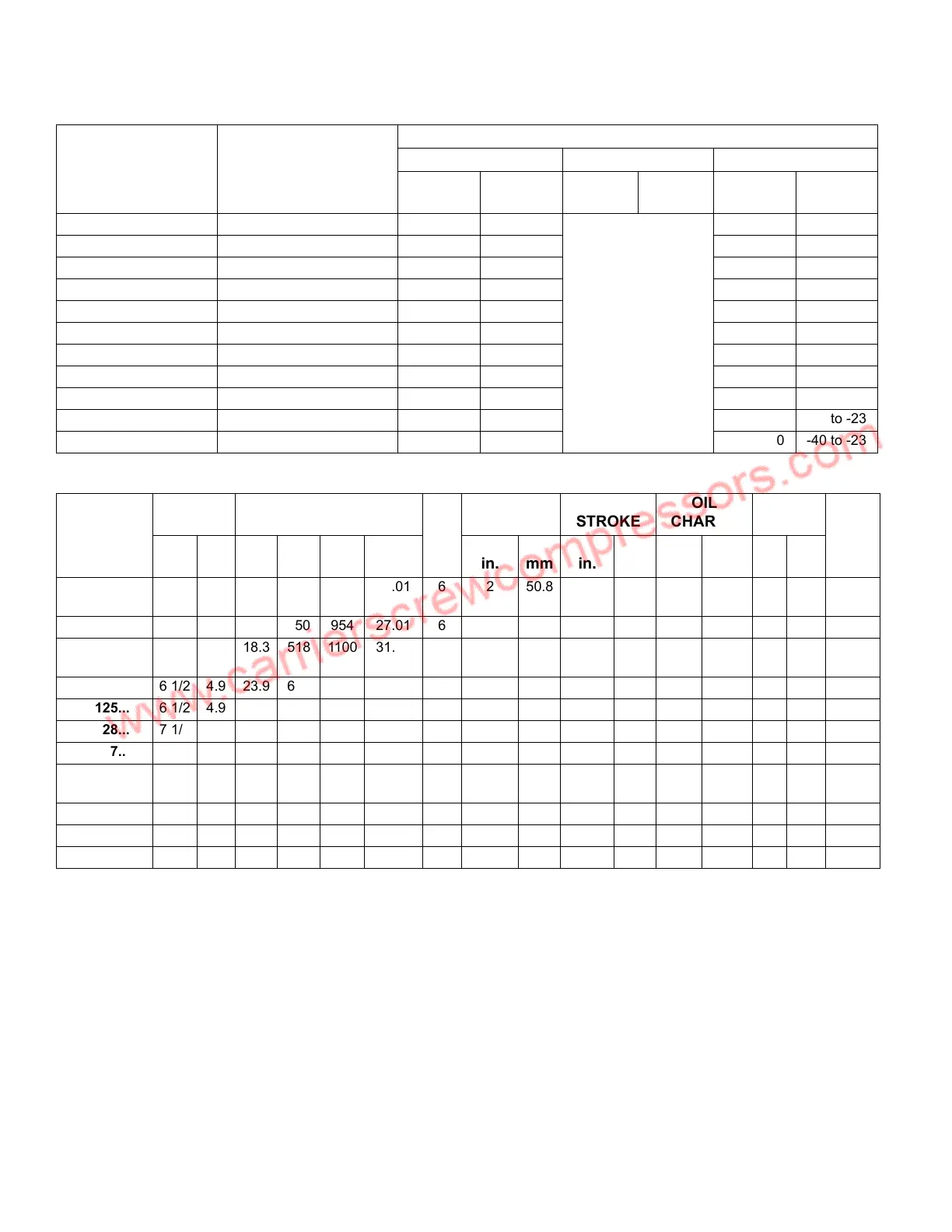

CARRIER /

CARLYLE

MODEL

NUMBER

MOTOR

SIZE

DISPLACEMENT AT

1750 RPM

NO.

OF

CYL

BORE STROKE

OIL

CHARGE

NET

WEIGHT

BODY

SIZEHP kW CFM L/M CFH

L/H

(1,000) in. mm in. mm Pints Liters lb kg

06CC016...

(See Note 2)

5 3.7 15.9 450 954 27.01 6 2 50.8 1 1/4 31.8 9.5 4.5 330 150 D

06CC017... 5 3.7 15.9 450 954 27.01 6 2 50.8 1 1/4 31.7 9.5 4.5 330 150 D

06CC018...

(See Note 2)

5 3.7 18.3 518 1100 31.09 6 2 50.8 1 15/32 37.3 9.5 4.5 325 147 D

06CC124... 6 1/2 4.9 23.9 677 1435 40.60 6 2 50.8 1 1/4 31.8 9.5 4.5 335 152 D

06CC125... 6 1/2 4.9 23.9 677 1435 40.60 6 2 50.8 1 1/4 31.8 9.5 4.5 330 150 D

06CC228... 7 1/2 5.6 28 793 1680 47.57 6 2 50.8 1 15/32 37.3 9.5 4.5 340 154 D

06CC337... 10 7.5 37.1 1050 2225 63.03 6 2 50.8 1 15/16 49.2 9.5 4.5 345 156 D

06CC550...

(See Note 2)

15 11.2 50.3 1424 3016 85.45 6 2 11/16 68.3 1 63/64 50.4 19 9.0 545 247 E

06CC665... 20 14.9 68.3 1934 4096 116.0 6 2 11/16 68.3 1 63/64 50.4 19 9.0 555 252 E

06CC675... 20 14.9 75.4 2135 4524 128.1 6 2 11/16 68.3 2 3/16 55.6 19 9.0 555 252 E

06CC899... 30 22.4 99.0 2803 5940 168.2 6 2 11/16 68.3 2 7/8 73.0 19 9.0 580 263 E

CFM — Cubic Feet Per Minute

L/H — Liters Per Hour

L/M — Liters Per Minute

Loading...

Loading...