2.5 Inverters and Refrigerants

The Carlyle screw compressor is compatible

with inverter drives. An inverter drive varies the

speed of a compressor to improve system load

matching.

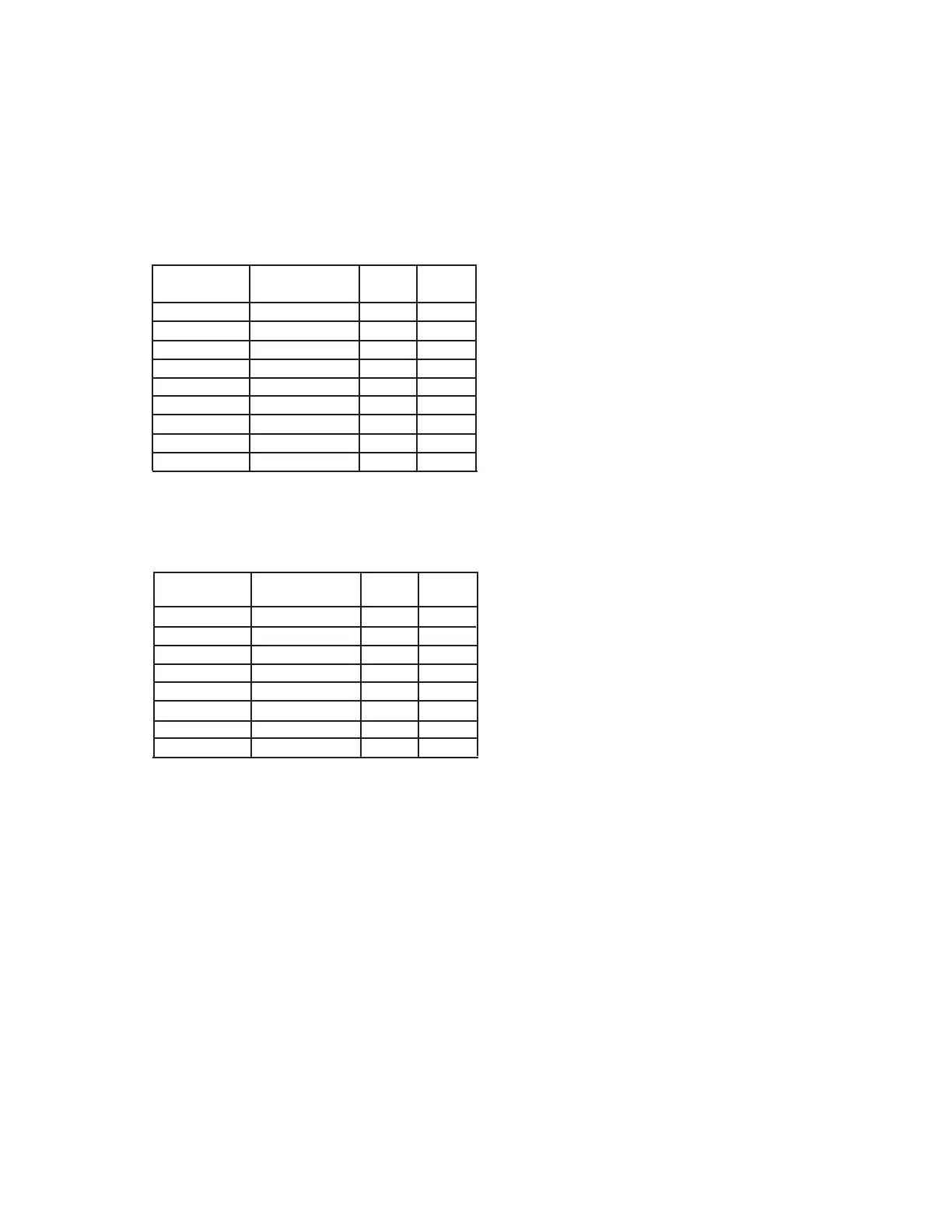

VARIABLE SPEED LIMITS

For 06TR Low Temp Compressors

Table 1

Model Nominal Min. Max.

No. HP Hz Hz

06TRC033 15 50 70

06TRD039 20 40 70

06TRD044 20 35 70

06TRE048 25 30 70

06TRE054 25 30 70

06TRF065 30 25 70

06TRG078 35 20 68

06TRH088 40 20 60

06TRK108 50 20 50

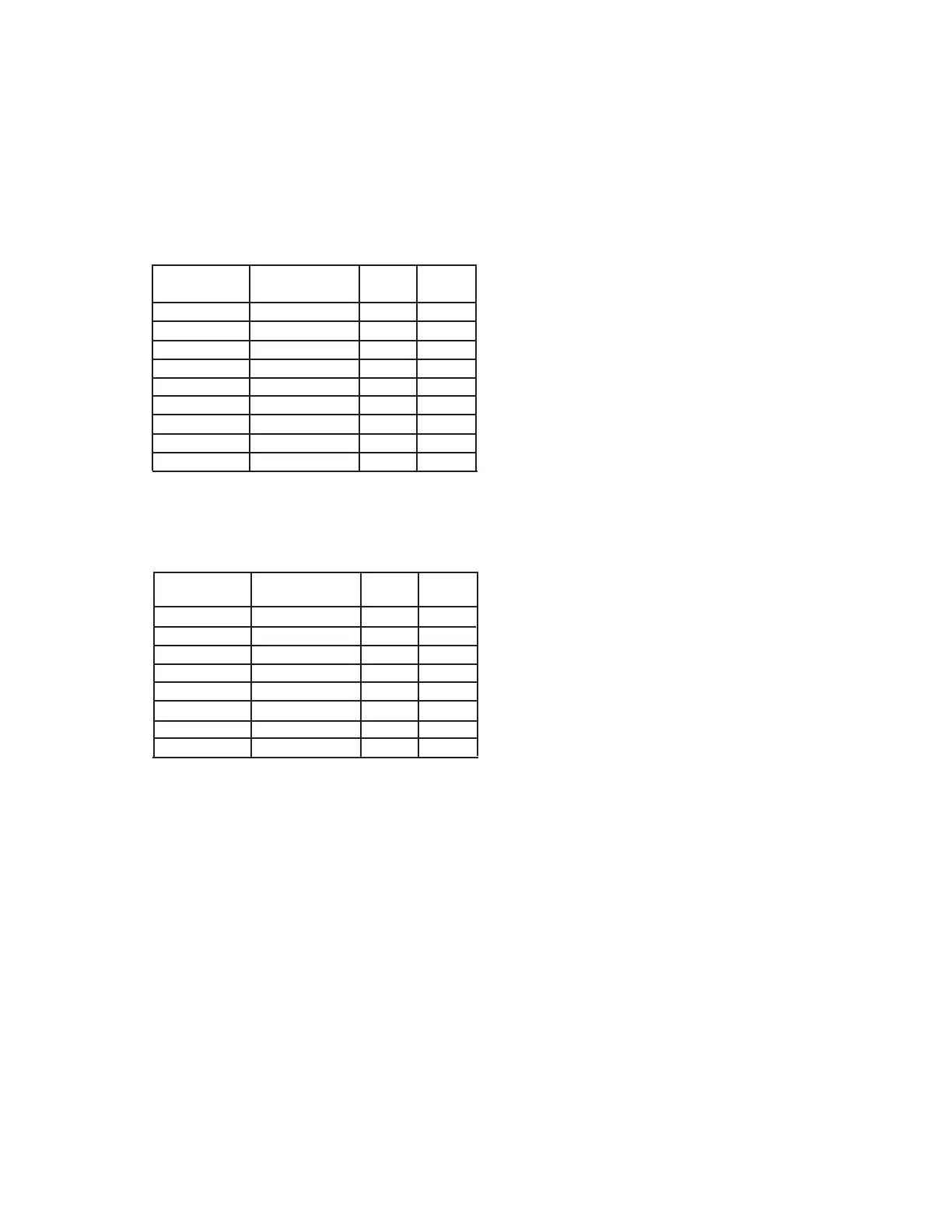

VARIABLE SPEED LIMITS

For 06TA A/C & Med. Temp Compressors

Table 2

Model Nom. Min. Max.

No. HP Hz Hz

06TAD033 20 50 70

06TAE039 25 40 70

06TAF044 30 35 70

06TAF048 30 30 70

06TAG054 35 30 70

06TAG065 35 25 70

06TAH078 40 20 68

06TAK088 50 20 60

Carlyle recommends screw compressors be

selected to match the system load at 60 Hz.

Overspeeding is a good option during heavy

load conditions. Carlyle does not recommend

the screw compressor operate at maximum

frequency for prolonged periods of time.

Operation above 60 Hz requires adequate

motor cooling. Inverters have a tendency to

increase the required motor cooling load due to

irregular wave forms. When overspeeding,

there will be an increased power consumption

required to supply the additional capacity. This

will also increase the required motor cooling

load. It is important that the motor cooling

system be capable of handling the increased

cooling required for the motor. Oil return,

economizer return gas, and the motor cooling

valve all assist in cooling the motor. Carlyle

recommends applying the largest motor cool-

ing valve (Carlyle P/N EF28BZ007) with all

screw compressors applied using inverters.

Inverters are an effective tool for efficiently

matching system loads with screw

compressors. Motor size and motor cooling

capabilities must be considered when using

an inverter to increase speeds above 60 Hz.

Following these guidelines will result in

improved system design and performance.

An inverter is capable of changing the

compressor’s speed very quickly from full

speed to minimum speed and vice versa.

Compressors should ramp-up to the minimum

speed within 15 seconds at start-up. After

compressor start, Carlyle recommends that the

rate of compressor speed change be limited to

600 RPM/Min for the 06T semi-hermetic. The

rate of compressor speed change for the

05T open drive models is required to be

no greater than 500 RPM/MIN.

2.6 Compressor Cycling

Although compressor cycling is an effective

means of capacity control, frequent starting

and stopping shortens the compressor life.

Carlyle screw compressors should not be

cycled for capacity control more than six

times an hour and should run for at least

5 minutes after each start.

8

Loading...

Loading...