2.11 Reverse Rotation Protection

Correct compressor rotation is critical for com-

pressor reliability. The compressor can fail with-

in 2-6 seconds of start-up if it is not rotating in

the correct direction. Installation of a pressure

gage at the discharge pressure access fitting in

the compressor body (measuring the pressure

upstream of the integral discharge check valve)

is recommended during initial start-up or

whenever the compressor is serviced. The

gage should be monitored to ensure increasing

discharge pressure at start-up.

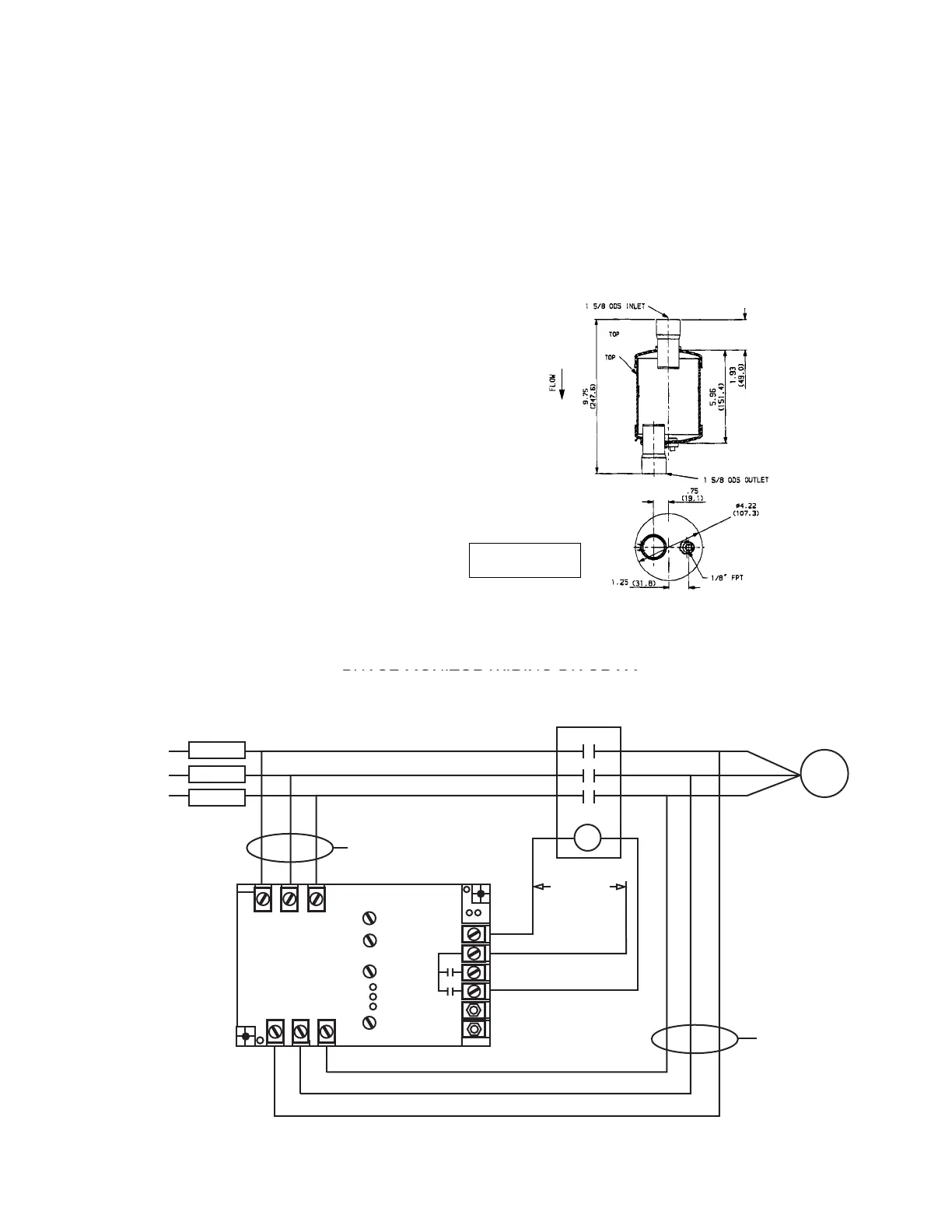

The new LonCEM protection module (available

midyear 2000) uses a pressure sensor to moni-

tor the discharge pressure change at start-up

to ensure proper compressor rotation. The

LonCEM module eliminates the need for a

mechanical low-pressure switch and line/load

phase monitor. See Appendix A for descrip-

tions of operation applications for the LonCEM

module.

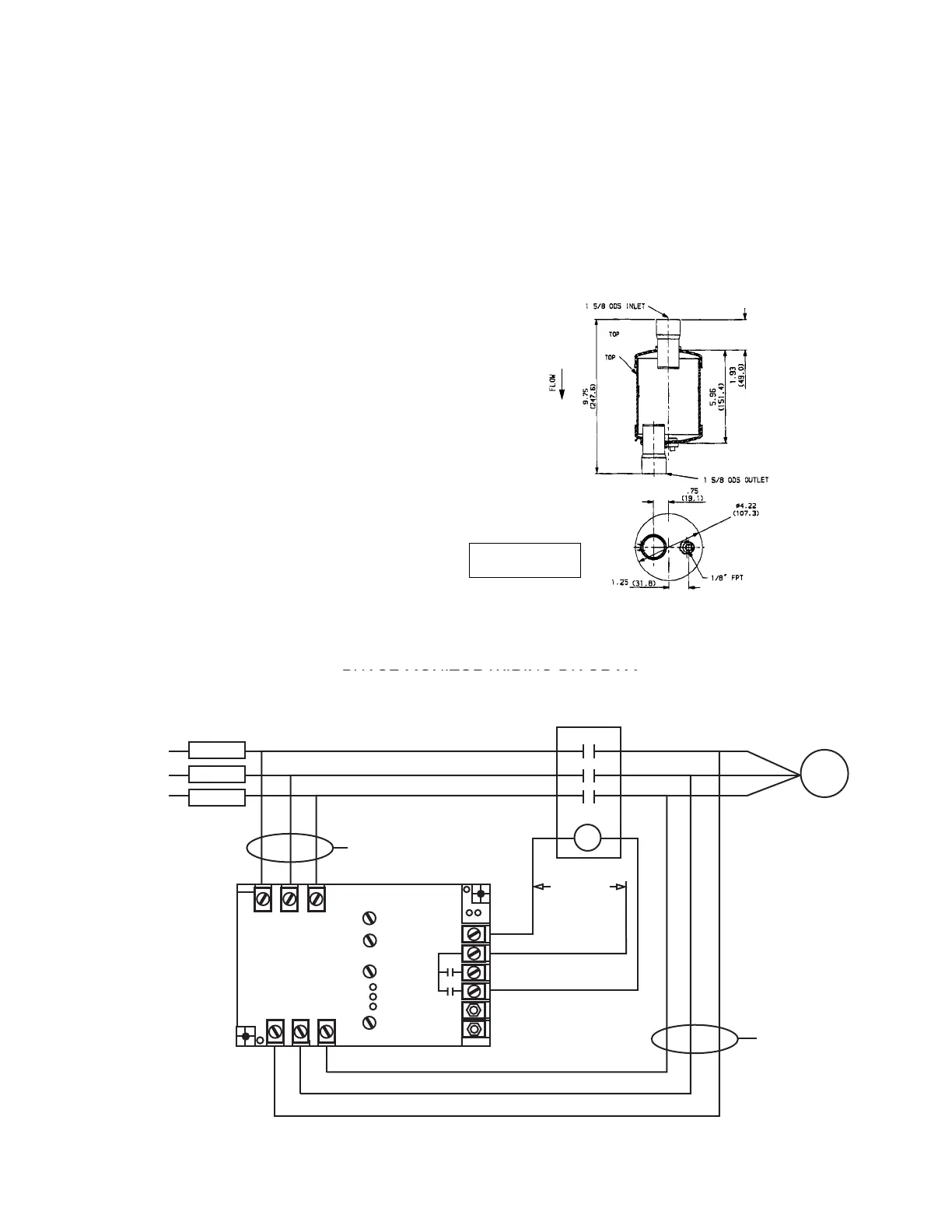

2.12 Mufflers

Screw compressors emit very high frequency

gas pulsations that have the potential to result

in significant discharge line and oil separator

noise. The addition of the Carlyle screw com-

pressor muffler is required in all applications to

reduce discharge line and oil separator noise

levels (Carlyle P/N LM10HH162). The muffler

should be located within 6-in. of the compres-

sor discharge service valve.

10

Loading...

Loading...