INSPECTION

Check cfankshaft

journals

lbr wear and

tolerances

(Table

1l). Remove crankshaft plugs.

check oil

passages

and clean if clogged.

Connecting-rod bearing inserts and main bearings arc avail

able for crankshafts reground fronr .010 in..

.0:0-in.. or

.030-in. undersized. Factory-reground crankshrfts are stamped

on bolh

ends

with

an A

(.010

in.

undersized), B

(.020

m.

undersized), or C

(.030-in.

undcrsized).

IMPORTANT: Do NOZ rcgrnrd cnnksh.ifts rbr

5H.16.

66,86, ?nd 126co

pressors

in the ilekl Rcplrce shriis

with

scored

journals.

All instructiotts

J'ar .lie

ld gtintling

dpplI onl\,to sldnldrrl-

On crankshafts reground locrlh', hold tlmw to 1.001

in.

for

5F compressors and to 1.376 in. on 5H compfessors.

Stanrp A

or

B

on

crankshaft ud punrp eDd

bearing head

next

to oil

pressLrre gage

conneclio .

'l'o

delermine maximum and minimum

i(rLnrrldirmeters

tbr

undenized shafts, subttuct the rnxrunt

(ir.)

th,ll the shali

wrll

be

grcund

rndcrsizc liom iict(ny fftnn the

tolerances

spccified

in Table lt. Fof exLrnrple, lhc iicr(r! tolerance

tbr 5H40

seal-end

joumrl

is 2.6225

in. lo 2.ar2l5 inches.

'folerancc

for x ctankshrfL rcgr,Nnd lo .010 in.

undersize

should

thercforc be held bctwccn 2 61215 in. dnd 1.6135

IMPORTANT:

Whcn regrindirrg rhc scrl'cnd.loumal

o 5H

120 cr,rnkshdi, do

rx)t

rrind

in rlrc arcr ol lhe

oil sepArAlor impcllcr. This is not

jourDrl

rrer, dnd

must

renrain intact or the oil

sepurur

in)pcllcr rvill

nol

iit

piopcdy.

REASSEMBLY

-

ll 5H120 ar 5H126 ail

u'pl|trtut hus

he!|

rc k^,ed, ftal i tr).llo

t,atuvaph

h?h\\ hefuk'

i

.

When rcgrinding

crdnkshlii,

rcnrovc

cranksh.rtt

plugs

rnd

clean oil

pLrsslgcs

ns well. B.linc rcpl.cing

cfttnkshati. in-

se rnd

tighten

plugs.

and reinstall rhe 5H120 rnd 116

oil

l.

Inse dowel kcy

(Fig.29)

with rxis prrallel

ro axis ol'

cr.rrkshrit.

Position key so chanrlcrcd cdgc is tow.rfd

radius oi crankshrit

iournrl.

2.

lnnDerse oil seprrlor impcller ir

oil or hol waler lo heal

it

to 180 F or nore If wrtcr is used, rennve

all traces

bcnrre

reassembly. lnsrall impeller or cmnkshaft with

dowcl key

lined up

with

inrpeller keyway. I

pcllcr

nrusl

fit key snugly.

Ir Check that seal-end thrust w$her is

in

place

on dowel

key

in crankcase.

Insert

crankshali and insrallpump-end bciring head,

con-

necting rod and piston dssemblies, valve plale

and cylinder

heads.

On 5H80 through 126 unns, inscrt

center main bear-

ing setscrew rnd lock screw

as describcd under

Selaicing

cen.er

\4r,r Ber in!. Or 5H46. .aj,nd

ll6unir,.r..Jn

necl oil line

to centef nlain bearing.

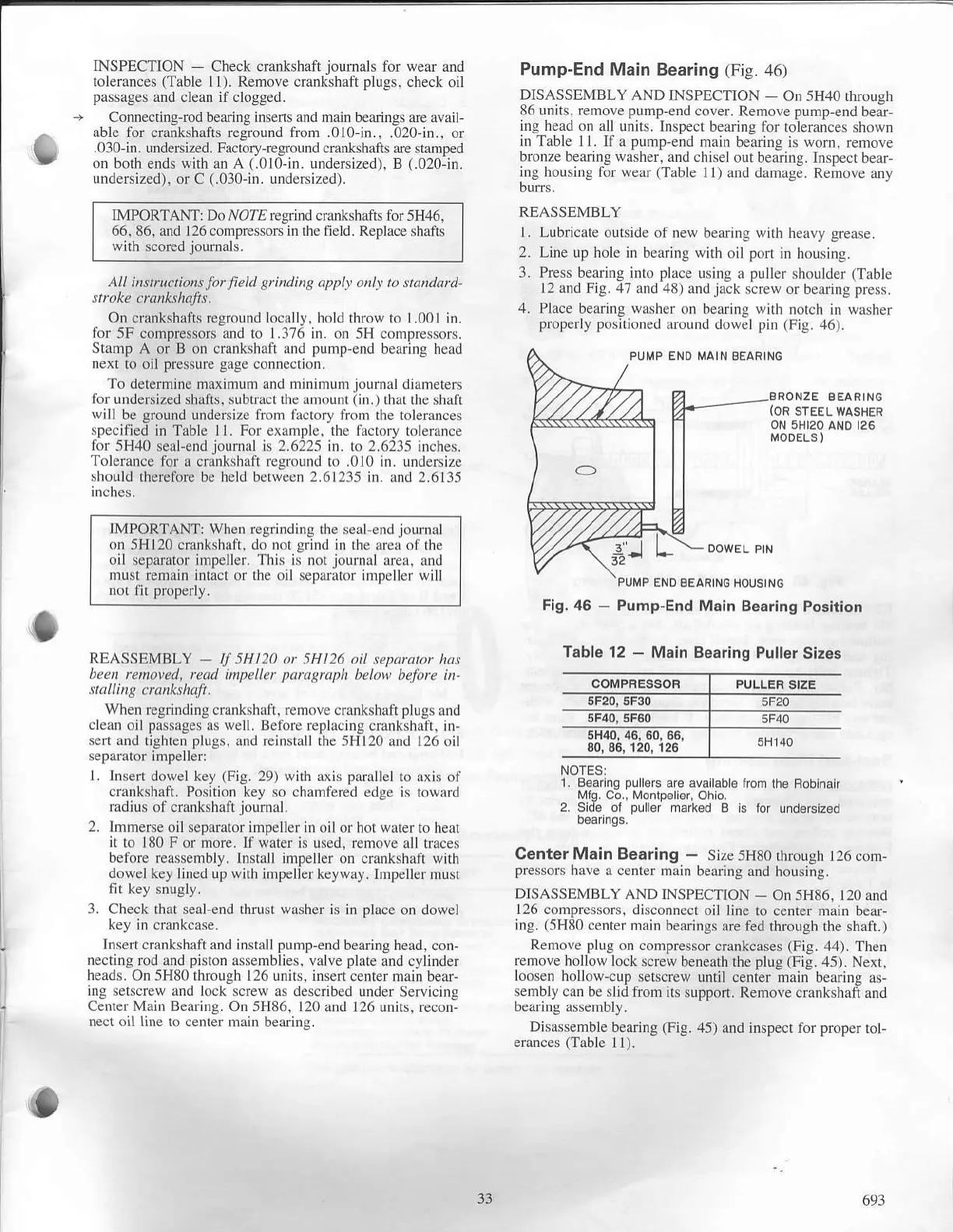

Pump-End

Main Bearing

(Fig.

46)

DISASSEMBLY AND

INSPECTION

On 5H.10 through

86 units. remove punp

cnd cover.

Renove

punrp

end beaf,

ing head on all

units. Inspecr bearmg for

tolerances shown

rn Table 11. II a

pump

end mair

bearing is worD. remove

b.onze

bearjng

washer.

and chiselout

bearing. inspcct

bear

ins houstug far wear

(Table

1l) and damrg;. Renrove

any

REASSEMBLY

1.

Lubricare outsid€ of new bearhg wirh

hcrvy grexse

) Line up nole .r bc.,r r! iirh

o.l o"|| .n l.{'.i ,!

l. Press bearing inLo phce u\in8

a

pullef

shouldef

{Table

L ,J FiF I

rnrr

rFr

drJ -.1

- eu

nr

l.(dr.

!

tr.\.

.1.

Place

bea.irg

washcr

on berring with

norch m w{slref

propcrly positioned

arcund dowcl piD

(Fi9.,16).

PUMP ENO MAIN BEARING

RONZE

BEAR NG

ON 5HLzO

AND I25

MODELS

)

PI]MP

END BEARING

NOUSING

0

Fig.46

-

Pump-End

Main Bearing

Position

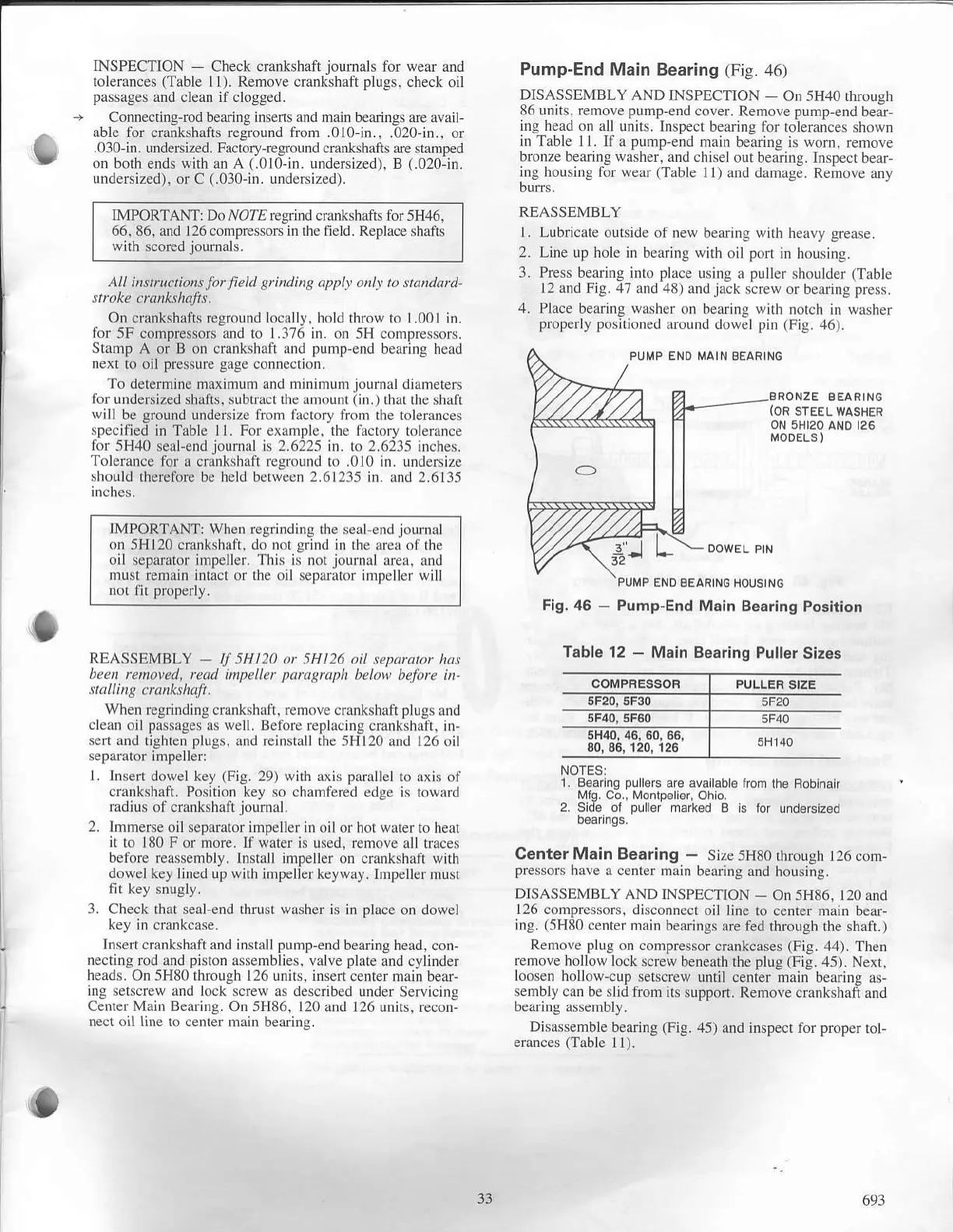

Table 12

-

Main Bearing

Puller

Sizes

NOTES

1. Bear ng

p!

l€rs

are avaitabte tom

lh€ Fobrnar

Mls. Co. Monlpeler Oh o

2. Side. ol

pller

marked

B is ior

lnd€rsized

Centei Main Bearing

-

Sizc

5H80 through 126 con!

pressors

have r cenLer

nrain bearing

and housing.

DISASSEMBLY

AND INSIIECTION

On5H86,

l20and

126 compressors.

disconncct

oil line ro cenrcr nraiD bear,

ing.

(5H80

cenler

main bearings

are fed through rhe shaii.)

Reffove

plug

on

conrpressor

crankcases

(Fi-s.

,14).

Then

reho\ehollou

lork."ewbenedr\rneplJB,Frr

4\' \e\r.

lo^! n hii l.u-.Jn

rer.rre$

rnlil cenrer n rin bedr rB :r.-

se bly can be.slid

fron i1s strpport.

Remove crankshali rnd

Disrssenrble

beffing

(Fig.

.15)

and inspecr lbr

proper

tol

eranccs

(Table

I t).

PULLER

SIZE

693

Loading...

Loading...