4.

3.

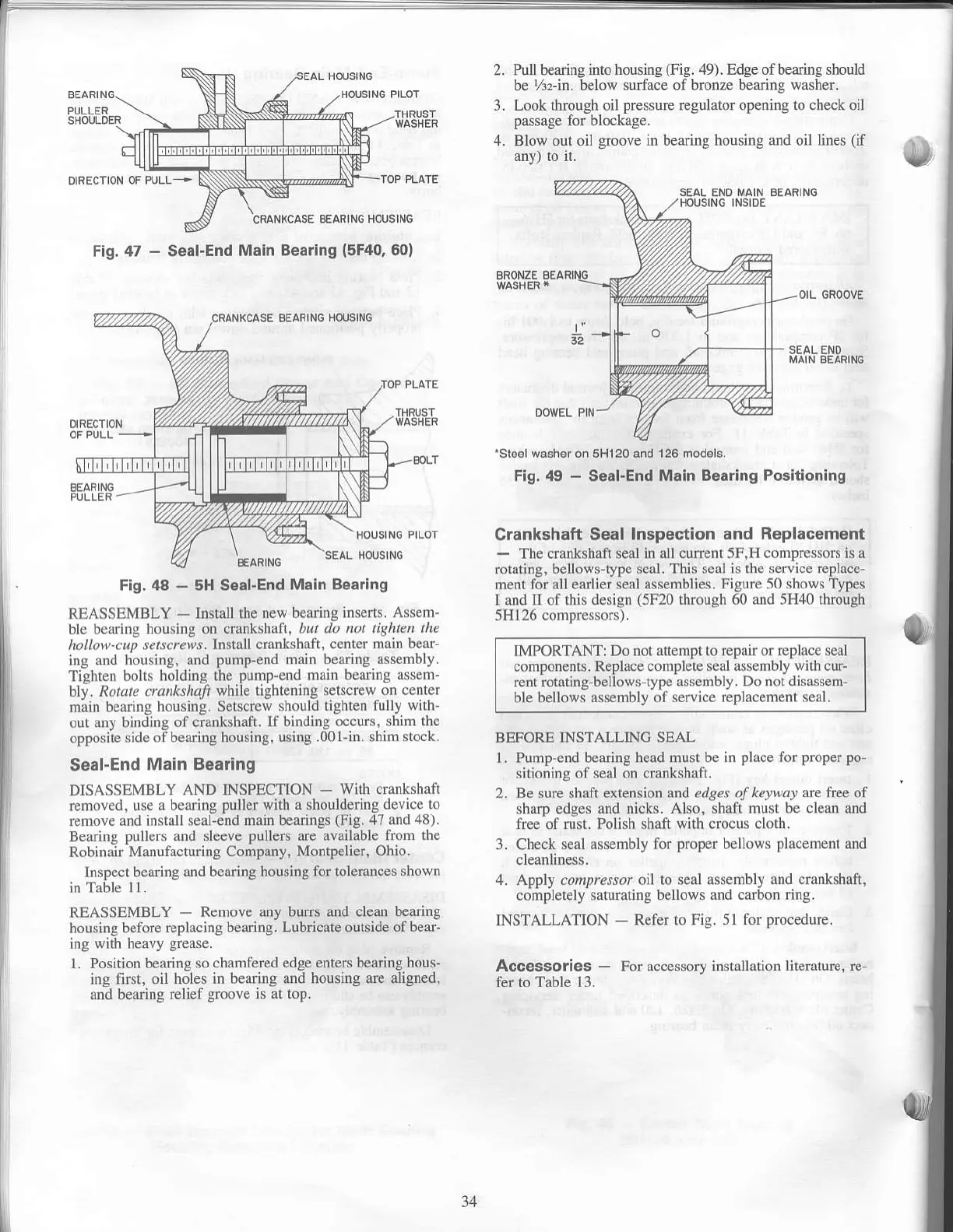

Pull beiring into

housing

(Fig.

49). Edge ofbearing should

be

%r-in. below surface of bronze bearing washer.

Look tlmugh oil

pressure

regulator opening

to

check oil

passage for blockage.

Blow out oil

groove

in bearing housing and oil lines

(if

any) to it.

SEAI. ENO iIAIN BEAiIiiIG

HOUSING INSIDE

BRONZE BE

KCASE BEAFIN6

HOUSING

SEAL ENO

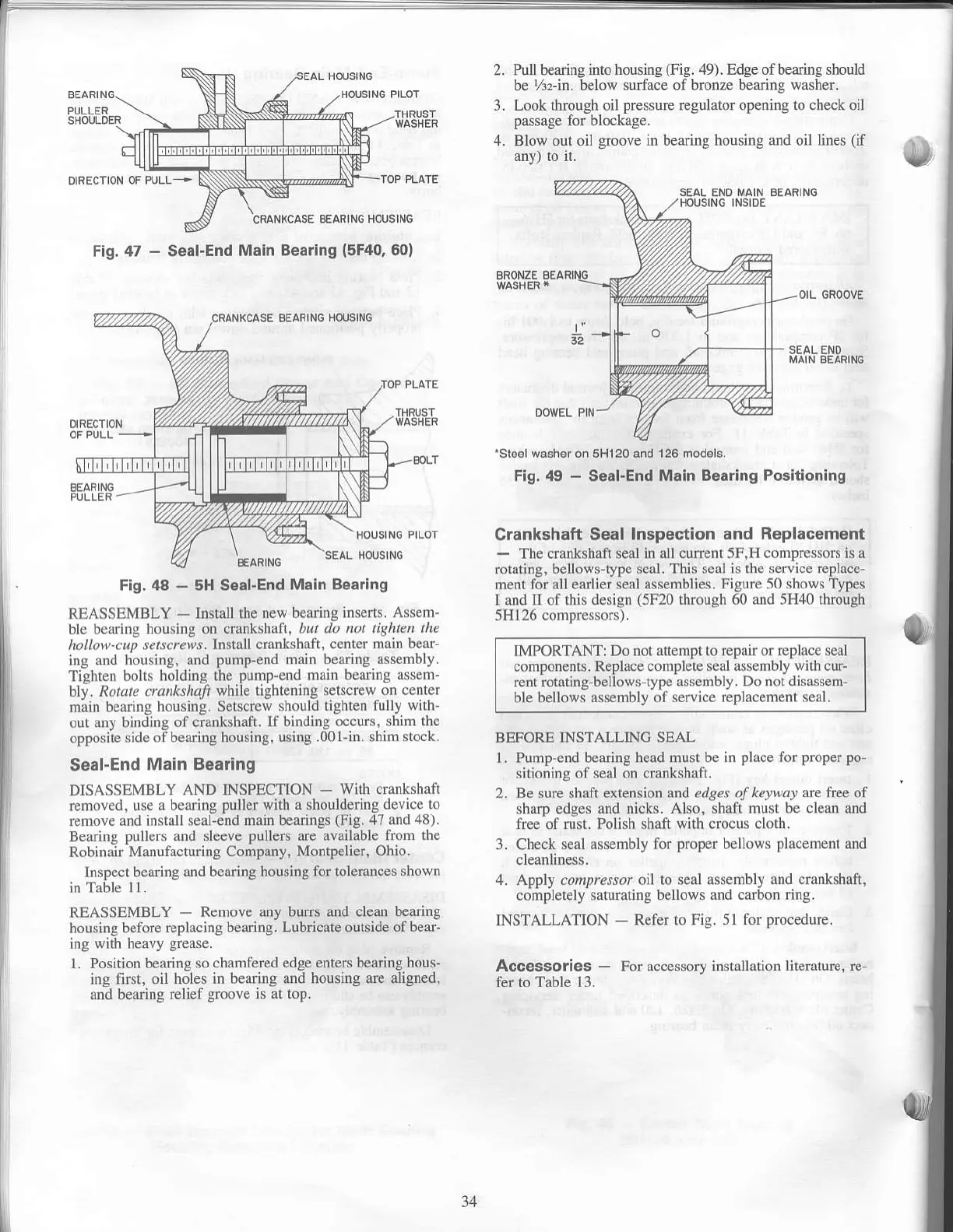

Fig,

,18

-

5H Soal-End

Main Bearing

REASSEMBLY

-

Install the

new bearing inserts.

Assem-

ble bearing housing on .ftnkshafr,

but do not

tiShten the

hollow-cuD setscrcrrs. lnstall crankshaft. center

main bear-

ing and

liousing, and

pump-end main bearing assemoty.

Tishten

bolls holding the

pump-end

main bearing

assem-

bly. Rotate crunkthall

while

lightening

setscrew on center

main bearing

housing. Setscrew should

tighten fuUy

wirh-

our anr bindins

of crankshaft. lf

bindins occurs, .hirn the

opposiie

'ide oibering housin8.

using .011-in. shim

stock.

Seal-End

Main Bearing

DISASSEMBLY AND INSPECTION

-

With crankshaft

removed.

u'e a bearing

puller with

a shoul(hring

device to

remore and install .ealie'nd main bearings

(Fig.47

and

48,.

Bearing

pullers

and sleeve

pullers

are available from

the

Robinair Manufacturing Company,

Montpelier, Ohio.

Inspect bearing

and b€aring housing for tolerances

shown

in Table

11.

REASSEMBLY

-

Remove any burN and clean bearing

housing before

replacing bearing. Lubricate outside

of bear-

ing with heavy

grease.

l Position bearing so

chamfered edge enters bearing hous-

jng

firsi, oil

holes in bearing and housing

are aligned,

and

bearing

relief

groove

is at top.

'S166lwash*

on 5H120 and 126 models.

Fig, 49

-

Sgal.End

Moin Boaring Positioning

Crankshsft

Soal Inspection and

Replacemont

-

The crankshaft seal in

all curr€nt 5F.H compre'sors is a

roraling, bellows-type seal. This seal is the service

replace-

ment for all eadier seal assemblies.

Figur€ 50 shows Types

I and II of this

design

(5M0

through 60 and 5H40 through

5H126 comoressors).

IMPORTANTT Do not attempt to

repair or replace seal

components. Replace complete

seal assembly with cur-

rent

rotating-bellows-type assembly. Do

not

disassen-

ble bellows

assembly of se ice replacement

seal,

BBFORE INSTALLINC SEAL

l. Pump-end bearing head musl

be in

place

for

prop€r po-

sitiooing of seal on

cmnkshaft.

2. Be sure shdt ext€nsion and edges of

kefwat arc tuee

of

sharp edges and nicks. Also,

shaft must be clean and

free

of rust.

Polish shaft with crocus cloth.

3. Check

seal assembly for

proper

bellows

placement

and

4. Apply compressor oil to seal assembly

and crankshaft,

completely saturating bellows

and carbon ring.

INSTALLATION

-

Refer to Fig. 51

for

procedure.

Accessories

-

For accessory installatron

lit€rature, r€-

fer to Table 13.

CRANKCASE BEAFING HOUSING

Fig. 47

-

Seal-End

Main Bearing

(5F40,

50)

34

Loading...

Loading...