Check Oil Pressure and Compressor Stop

1.

When the motor is up to full speed, note the differential oil pressure reading on the LID

default screen. It should be between 18 and 30 psid (124 to 206 kPad).

2.

Press the Stop button and listen for any unusual sounds from the compressor as it coasts to

a stop.

Calibrate Motor Current Demand Setting

1.

Make sure that the compressor motor rated load amps in the Service1 screen has been

configured. Place an ammeter on the line that passes through the motor load current

transfer on the motor side of the power factor correction capacitors (if provided).

2.

Start the compressor and establish a steady motor current value between 70% and 100%

CAUTION

CAUTION

!

Do not check motor rotation during coastdown. Rotation may have reversed dur-

ing equalization of vessel pressures.

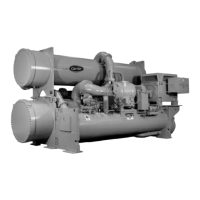

Click here for Figure 30 — Correct Motor Rotation

Loading...

Loading...