Unit-Mounted Wye-Delta Starter (Optional)

—

The 19XR chiller may be equipped with a wye-delta starter

mounted on the unit. This starter is intended for use with

low-voltage motors (under 600 v). It reduces the starting

current inrush by connecting each phase of the motor

windings into a wye configuration. This occurs during the

starting period when the motor is accelerating up to speed.

Once the motor is up to speed, the starter automatically con-

nects the phase windings into a delta configuration. Starter

control, monitoring, and motor protection is provided by

Carrier’s Integrated Starter Module (ISM).

CONTROLS

Definitions

ANALOG SIGNAL — An analog signal varies in propor-

tion to the monitored source. It quantifies values between

operating limits. (Example: A temperature sensor is an ana-

log device because its resistance changes in proportion to

the temperature, generating many values.)

DISCRETE SIGNAL — A discrete signal is a 2-position rep-

resentation of the value of a monitored source. (Example: A

switch produces a discrete signal indicating whether a value

is above or below a set point or boundary by generating an

on/off, high/low, or open/closed signal.)

General — The 19XR hermetic centrifugal liquid chiller

contains a microprocessor-based control center that moni-

tors and controls all operations of the chiller (see Fig. 7).

The microprocessor control system matches the cooling

capacity of the chiller to the cooling load while providing

state-of-the-art chiller protection. The system controls cool-

ing load within the set point plus the deadband by sensing

the leaving chilled water or brine temperature and regula-

ting the inlet guide vane via a mechanically-linked actuator

motor. The guide vane is a variable flow pre-whirl assem-

bly that controls the refrigeration effect in the cooler by

regulating the amount of refrigerant vapor flow into the com-

pressor. An increase in guide vane opening increases capac-

ity. Adecrease in guide vane opening decreases capacity. The

microprocessor-based control center protects the chiller by

monitoring the digital and analog inputs and executing

capacity overrides or safety shutdowns, if required.

PIC II System Components — The chiller control

system is called the PIC II (Product Integrated Control II).

See Table 1. The PIC II controls the operation of the chiller

by monitoring all operating conditions. The PIC II can di-

agnose a problem and let the operator know what the prob-

lem is and what to check. It promptly positions the guide

vanes to maintain leaving chilled water temperature. It can

interface with auxiliary equipment such as pumps and cool-

ing tower fans to turn them on when required. It continually

checks all safeties to prevent any unsafe operating condi-

tion. It also regulates the oil heater while the compressor is

off and regulates the hot gas bypass valve, if installed. The

PIC II controls provide critical protection for the compres-

sor motor and controls the motor starter.

5

1

2

3

4

6

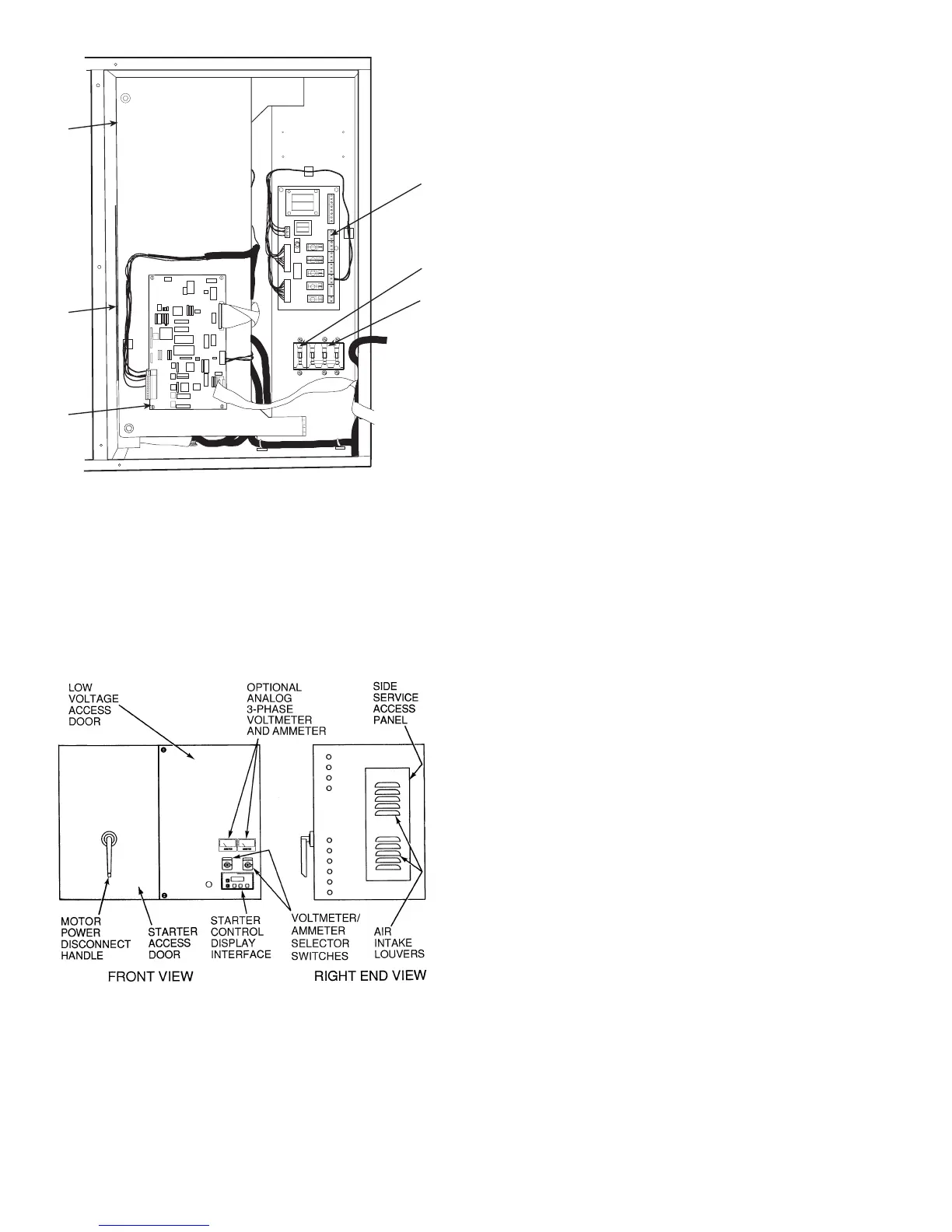

LEGEND

1—Ready-Start Micro Input/Output Card

2—Circuit Breaker 2 (CB2):

Machine Control and Heater Power

3—Circuit Breaker 3 (CB3): Oil Pump Power

4—Ready-Start Micro Central Processing Unit Card (CPU)

5—Restart Micro Power Card (hidden, not depicted)

6—Restart Micro Bypass Card (hidden, not depicted)

Fig. 5 — Solid-State Starter Box,

Internal View

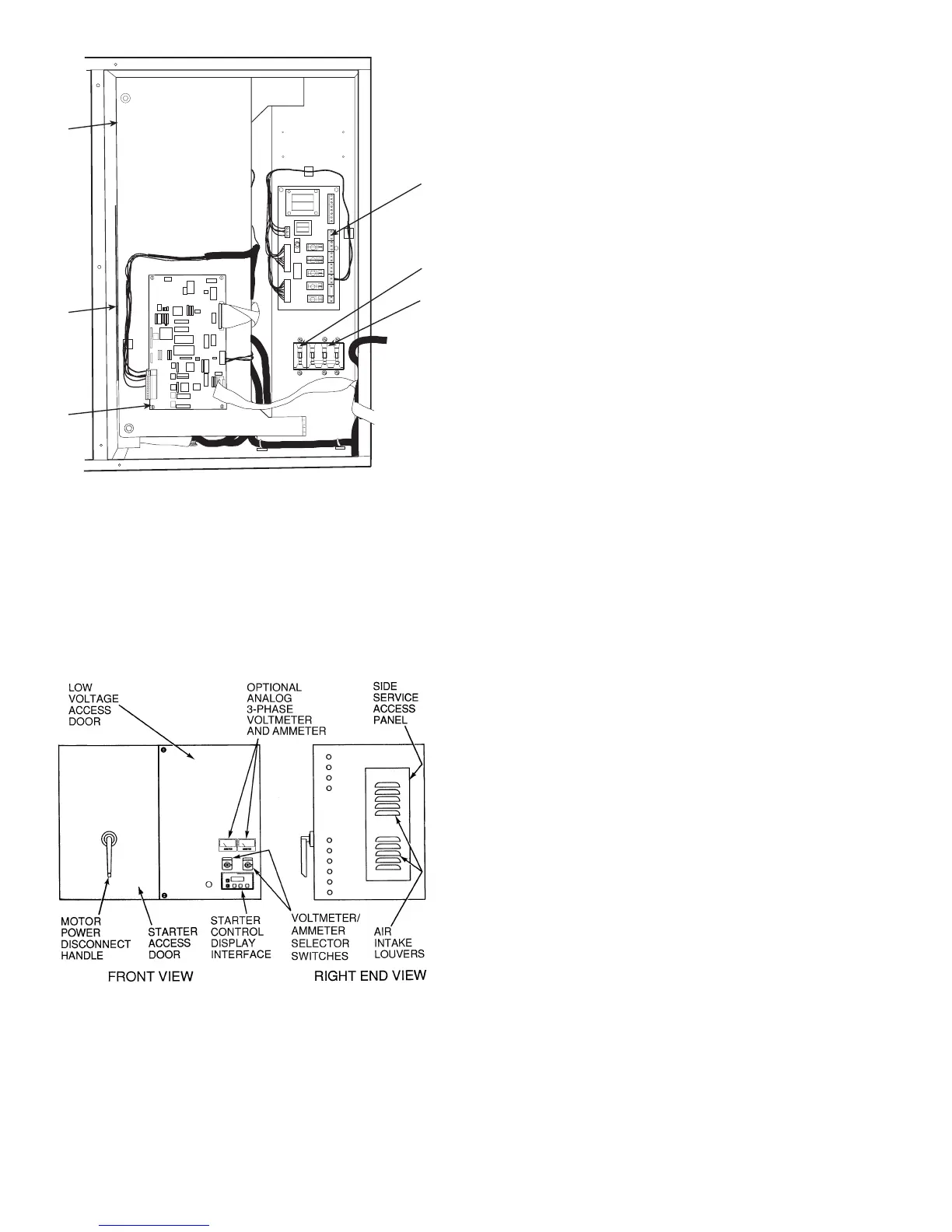

Fig.6—Typical Starter External View

(Solid-State Starter Shown)

10

Loading...

Loading...