The PIC II can interface with the Carrier Comfort Net-

work (CCN) if desired. It can communicate with other

PIC I or PIC II equipped chillers and other CCN devices.

The PIC II consists of 3 modules housed inside 3 major

components. The component names and corresponding con-

trol voltages are listed below (also see Table 1):

• control panel

— all extra low-voltage wiring (24 v or less)

• power panel

— 230 or 115 v control voltage (per job requirement)

— up to 600 v for oil pump power

• starter cabinet

— chiller power wiring (per job requirement)

Table 1 — Major PIC Components and

Panel Locations*

PIC II COMPONENT PANEL LOCATION

Chiller Visual Controller (CVC) and Display Control Panel

Integrated Starter Module (ISM) Starter Cabinet

Chiller Control Module (CCM) Control Panel

Oil Heater Contactor (1C) Power Panel

Oil Pump Contactor (2C) Power Panel

Hot Gas Bypass Relay (3C) (Optional) Power Panel

Control Transformers (T1, T2) Power Panel

Temperature Sensors See Fig. 7.

Pressure Transducers See Fig. 7.

*See Fig. 5 and Fig. 7-11.

CHILLER VISUAL CONTROLLER (CVC) — The CVC is

the ‘‘brain’’ of the PIC II. This module contains all the op-

erating software needed to control the chiller. The CVC is

mounted to the control panel (Fig. 10) and is the input center

for all local chiller set points, schedules, configurable

functions, and options. The CVC has a stop button, an alarm

light, four buttons for logic inputs, and a backlight display.

The backlight will automatically turn off after 15 minutes of

non-use. The functions of the four buttons or ‘‘softkeys’’ are

menu driven and are shown on the display directly above

the softkeys.

The viewing angle of the CVC can be adjusted for opti-

mum viewing. Remove the 2 bolts connecting the control

panel to the brackets attached to the cooler. Place them in

one of the holes to pivot the control panel forward to back-

ward to change the viewing angle. See Fig. 10. To change

the contrast of the display, access the adjustment on the back

of the CVC. See Fig. 10.

INTEGRATED STARTER MODULE (ISM) — This mod-

ule is located in the starter cabinet. This module initiates com-

mands from the CVC for starter functions such as starting

and stopping the compressor, condenser, chilled water pumps,

tower fan, spare alarm contacts, and the shunt trip. The ISM

monitors starter inputs such as line voltage, motor current,

ground fault, remote start contact, spare safety, condenser

high pressure, oil pump interlock, starter 1M, and run con-

tacts. The ISM contains logic capable of safety shutdown. It

shuts down the chiller if communications with the CVC

are lost.

CHILLER CONTROL MODULE (CCM) — This module

is located in the control panel. The CCM provides the input

and outputs necessary to control the chiller. This module moni-

tors refrigerant pressure, entering and leaving water tem-

peratures, and outputs control for the guide vane actuator,

oil heaters, and oil pump. The CCM is the connection point

for optional demand limit, chilled water reset, remote tem-

perature reset, and refrigerant leak sensor.

OIL HEATER CONTACTOR (1C) — This contactor is lo-

cated in the power panel (Fig. 11) and operates the heater at

either 115 or 230 v. It is controlled by the PIC II to maintain

oil temperature during chiller shutdown.

OIL PUMP CONTACTOR (2C) — This contactor is located

in the power panel. It operates all 200 to 575-v oil pumps.

The PIC II energizes the contactor to turn on the oil pump

as necessary.

HOT GAS BYPASS CONTACTOR RELAY (3C) (Op-

tional) — This relay, located in the power panel, controls the

opening of the hot gas bypass valve. The PIC II energizes

the relay during low load, high lift conditions.

CONTROL TRANSFORMERS (T1, T2) — These trans-

formers convert incoming control voltage to 24 vac power

for the 3 power panel contactor relays, CCM, and CVC.

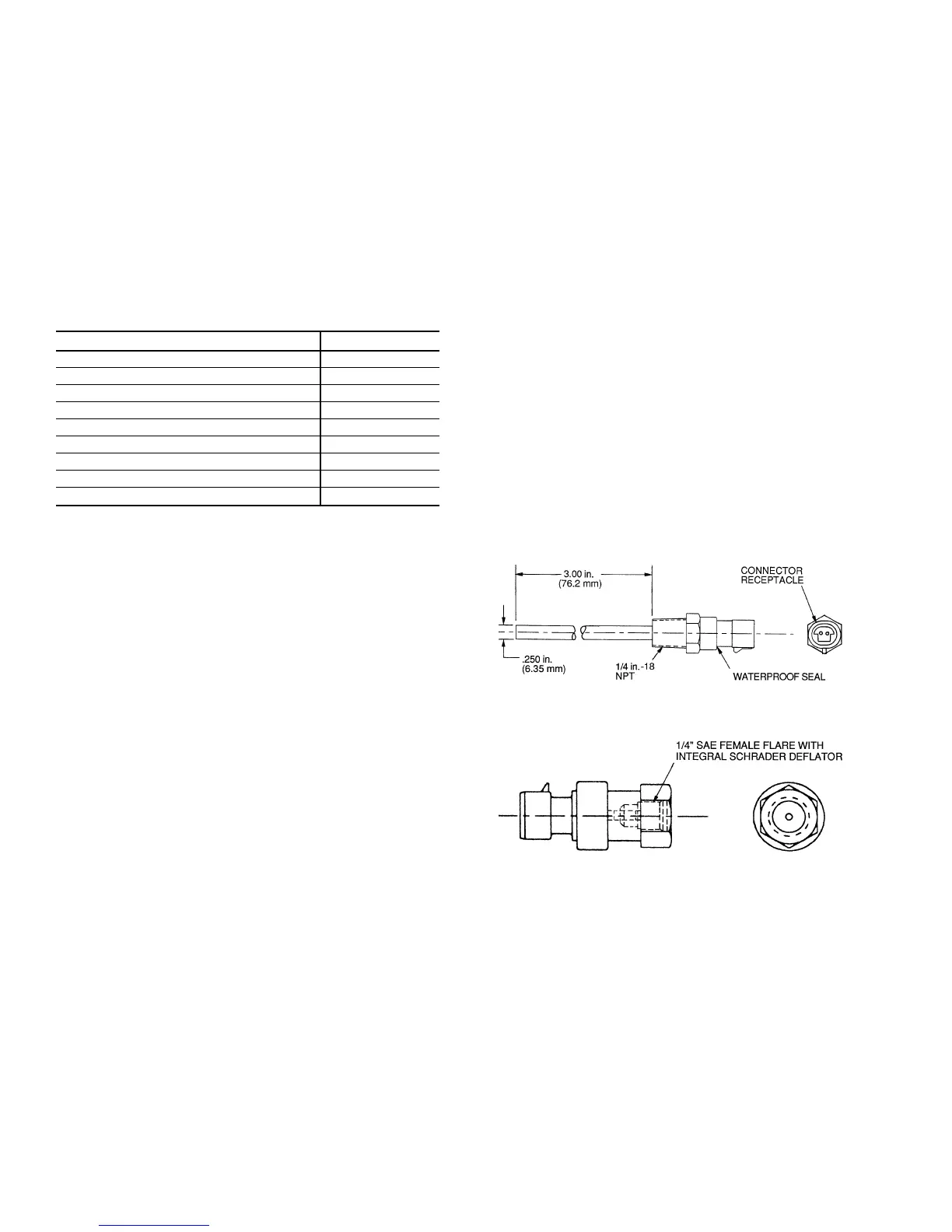

Fig. 8 — Control Sensors (Temperature)

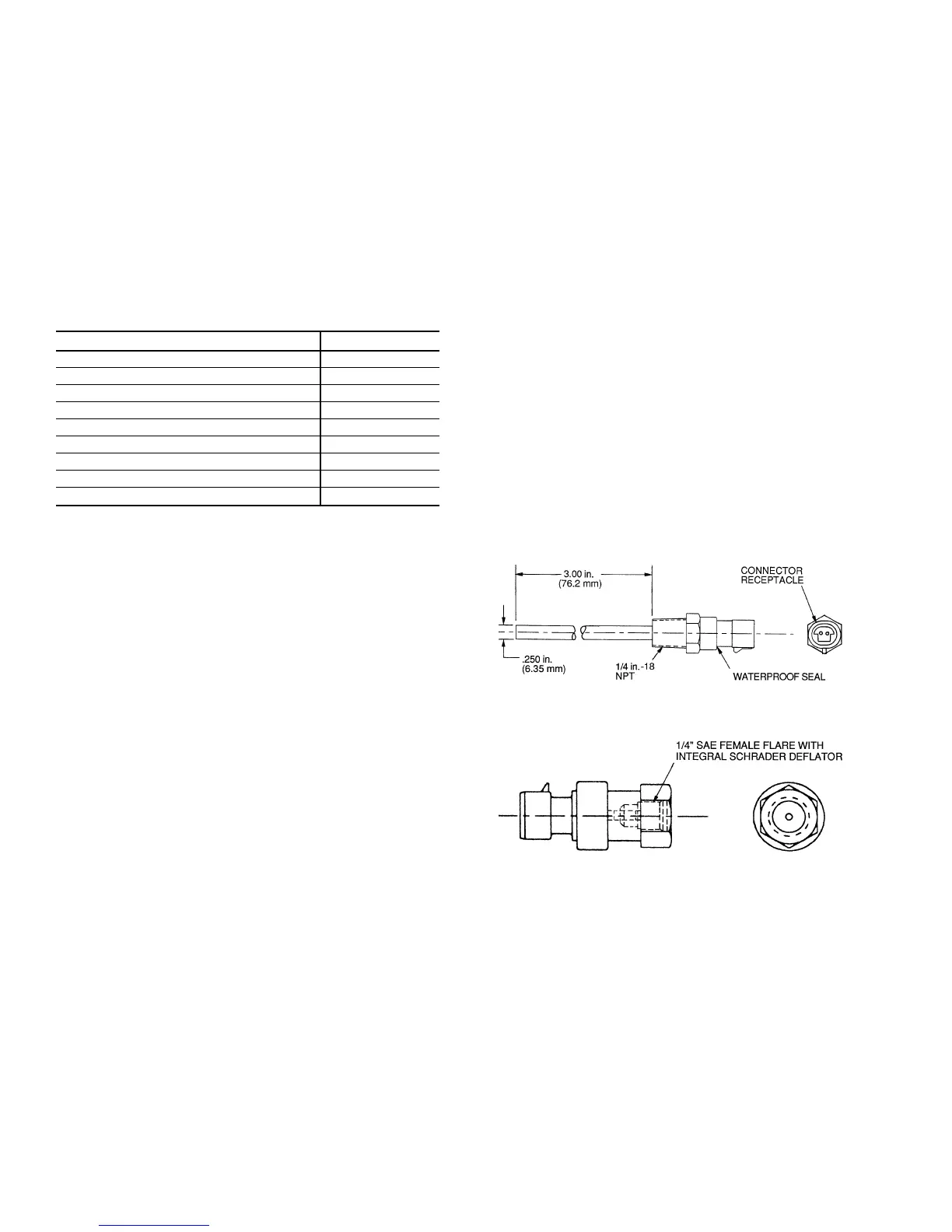

Fig. 9 — Control Sensors

(Pressure Transducers, Typical)

12

Loading...

Loading...