These maintenance screens are very useful in helping to

determine how the control temperature is calculated and guide

vane positioned and for observing the reactions from load

changes, control point overrides, hot gas bypass, surge pre-

vention, etc. The tables are:

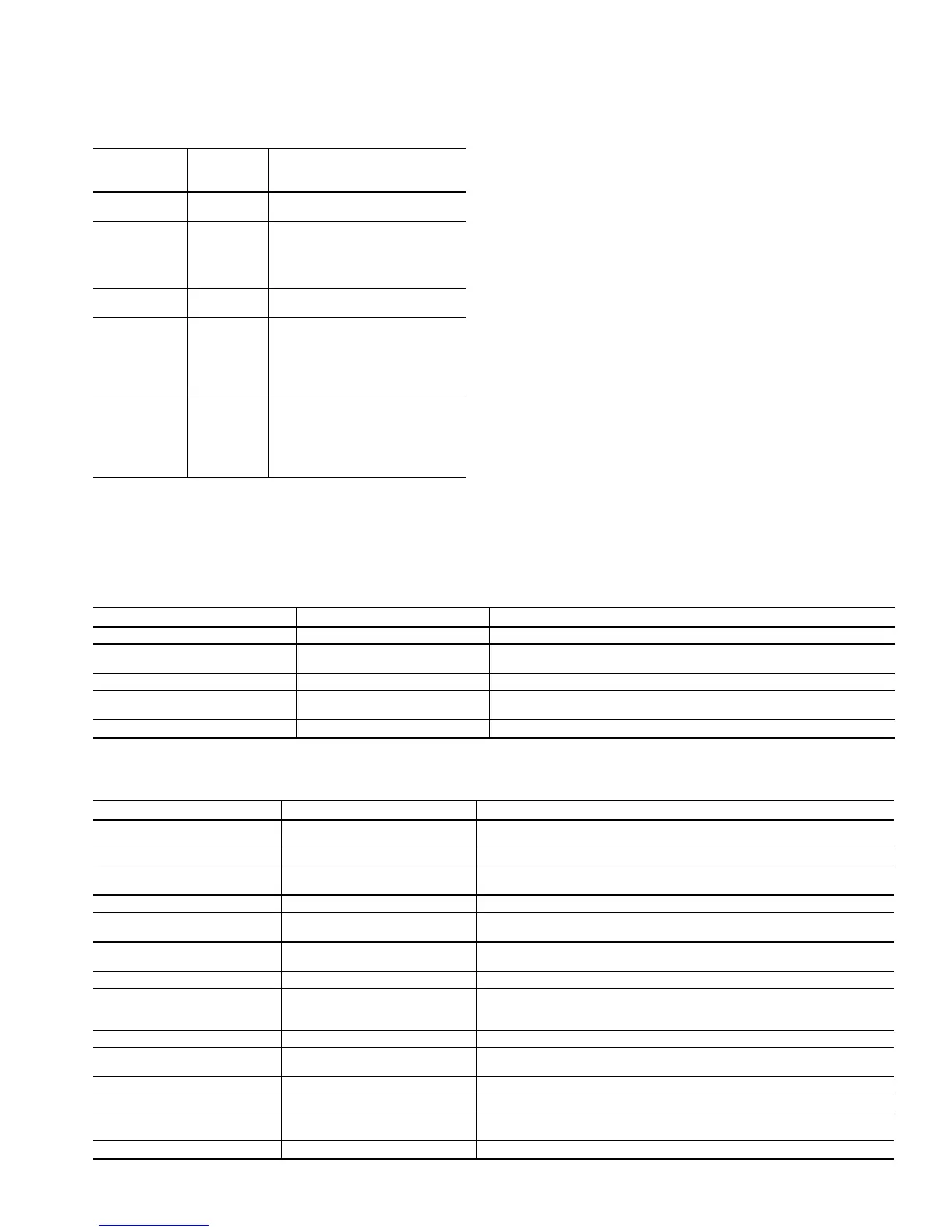

CAPACITY Capacity

Control

This table shows all values

used to calculate the chilled

water/brine control point.

OVERRIDE Override

Status

Details of all chilled water con-

trol override values.

HEAT_EX Surge/

HGBP

Status

The surge and hot gas bypass

control algorithm status is

viewed from this screen. All

values dealing with this control

are displayed.

LL_MAINT LEAD/LAG

Status

Indicates LEAD/LAG operation

status.

OCCDEFCM Time

Schedules

Status

The Local and CCN occupied

schedules are displayed here

to help the operator quickly de-

termine whether the schedule

is in the 9occupied9 mode or

not.

WSMDEFME Water

System

Manager

Status

The water system manager is a

CCN module that can turn on

the chiller and change the

chilled water control point. This

screen indicates the status of

this system.

Control Test — The Control Test feature can check all

the thermistor temperature sensors, pressure transducers, pumps

and their associated flow devices, the guide vane actuator,

and other control outputs such as hot gas bypass. The tests

can help to determine whether a switch is defective or a pump

relay is not operating, as well as other useful troubleshoot-

ing issues. During pumpdown operations, the pumps are en-

ergized to prevent freeze-up and the vessel pressures and

temperatures are displayed. The Pumpdown/Lockout fea-

ture prevents compressor start-up when there is no refrig-

erant in the chiller or if the vessels are isolated. The Termi-

nate Lockout feature ends the Pumpdown/Lockout after the

pumpdown procedure is reversed and refrigerant is added.

LEGEND TO TABLES 8A - 8J

CCM — Chiller Control Module

CVC — Chiller Visual Control

CHW — Chilled Water

ISM — Integrated Starter Module

PIC II — Product Integrated Control II

VFD — Variable Frequency Drive

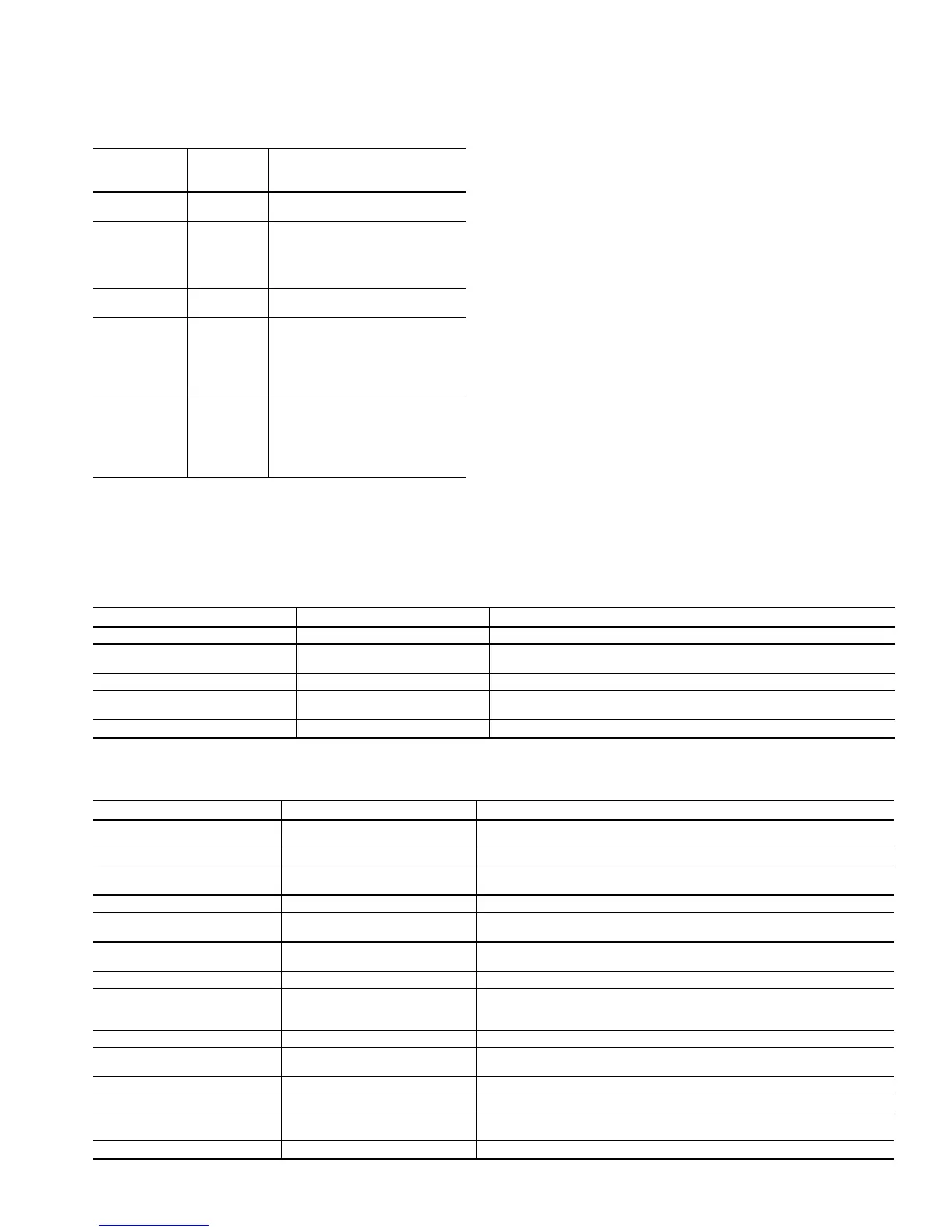

Table 8 — CVC Primary and Secondary Messages and

Custom Alarm/Alert Messages with Troubleshooting Guides

A. MANUAL STOP

PRIMARY MESSAGE SECONDARY MESSAGE PROBABLE CAUSE/REMEDY

MANUALLY STOPPED — PRESS CCN OR LOCAL TO START PIC II in OFF mode, press CCN or LOCAL softkey to start unit.

TERMINATE PUMPDOWN MODE TO SELECT CCN OR LOCAL Enter the CONTROL TEST table and select TERMINATE LOCKOUT to

unlock compressor.

SHUTDOWN IN PROGRESS COMPRESSOR UNLOADING Chiller unloading before shutdown due to soft/stop feature.

SHUTDOWN IN PROGRESS COMPRESSOR DEENERGIZED Chiller compressor is being commanded to stop. Water pumps are

deenergized within one minute.

ICE BUILD OPERATION COMPLETE Chiller shutdown from Ice Build operation.

B. READY TO START

PRIMARY MESSAGE SECONDARY MESSAGE PROBABLE CAUSE/REMEDY

READY TO START IN XX MIN UNOCCUPIED MODE Time schedule for PIC II is unoccupied. Chillers will start only when

occupied.

READY TO START IN XX MIN REMOTE CONTACTS OPEN Remote contacts are open. Close contacts to start.

READY TO START IN XX MIN STOP COMMAND IN EFFECT Chiller START/STOP on MAINSTAT manually forced to stop. Release

point to start.

READY TO START IN XX MIN OCCUPIED MODE Chiller timer counting down. Unit ready to start.

READY TO START IN XX MIN REMOTE CONTACTS CLOSED Chiller timer counting down. Unit ready to start. Remote contact enabled

and closed.

READY TO START IN XX MIN START COMMAND IN EFFECT Chiller START/STOP on MAINSTAT manually forced to start. Release

value to start under normal control.

READY TO START IN XX MIN RECYCLE RESTART PENDING Chiller in recycle mode.

READY TO START UNOCCUPIED MODE Time schedule for PIC II is unoccupied. Chiller will start when occupied.

Make sure the time and date are correct. Change values in TIME AND

DATE screen.

READY TO START REMOTE CONTACTS OPEN Remote contacts have stopped the chiller. Close contacts to start.

READY TO START STOP COMMAND IN EFFECT Chiller START/STOP on MAINSTAT manually forced to stop. Release

point to start.

READY TO START OCCUPIED MODE Chiller timers complete, unit start will commence.

READY TO START REMOTE CONTACTS CLOSED Chiller timer counting down. Unit ready for start.

READY TO START START COMMAND IN EFFECT Chiller START/STOP on MAINSTAT has been manually forced to start.

Chiller will start regardless of time schedule or remote contact status.

STARTUP INHIBITED LOADSHED IN EFFECT CCN loadshed module commanding chiller top stop.

71

Loading...

Loading...