14

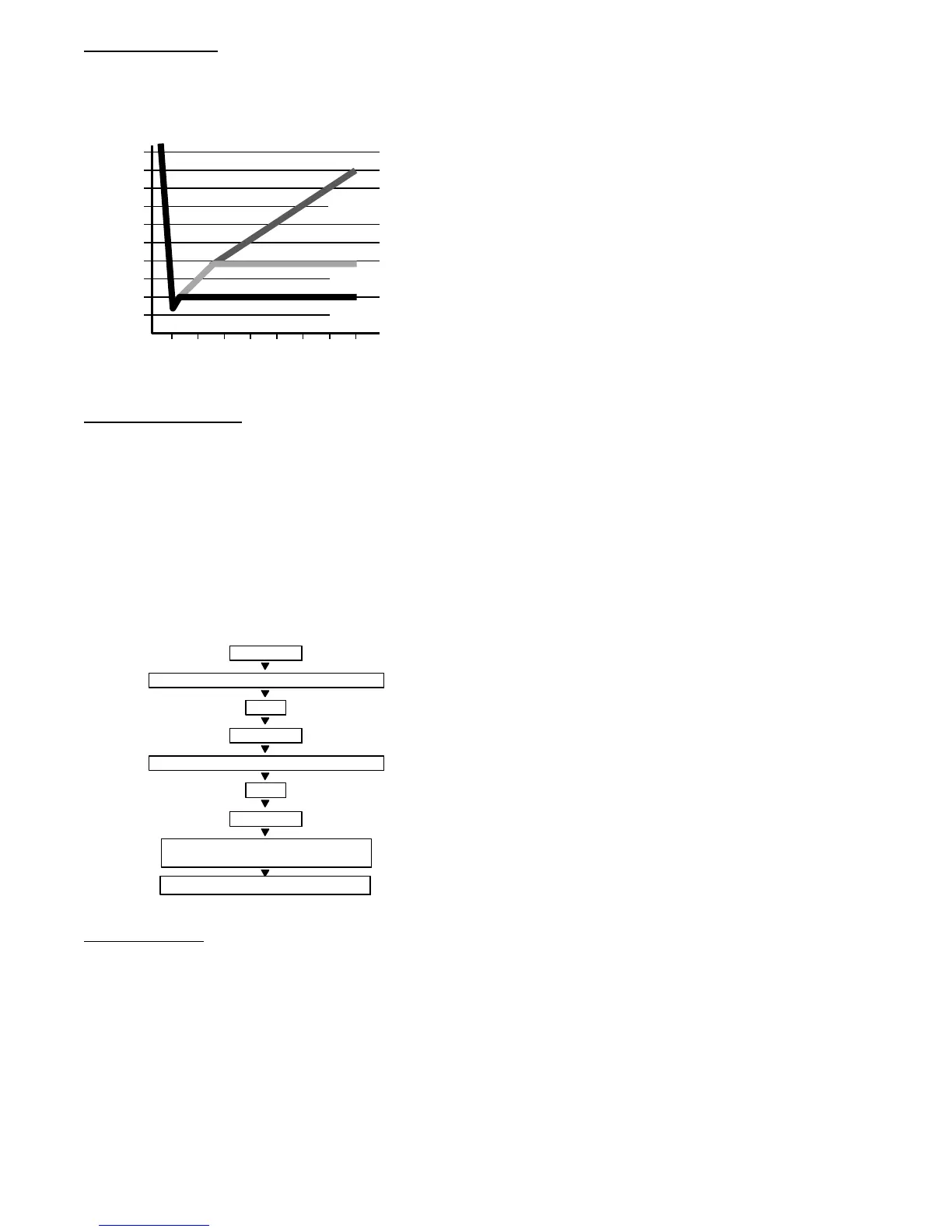

Deep Vacuum

Method

The deep vacuum method requires a vacuum pump capable of

pulling a vacuum of 500 microns and a vacuum gage capable of

accurately measuring this vacuum depth. The deep vacuum method

is the most positive way of assuring a system is free of air and

liquid water (see Fig. 16).

500

MINUTES

01234567

1000

1500

LEAK IN

SYSTEM

VACUUM TIGHT

TOO WET

TIGHT

DRY SYSTEM

2000

MICRONS

2500

3000

3500

4000

4500

5000

Fig. 16 – Deep Vacuum Graph

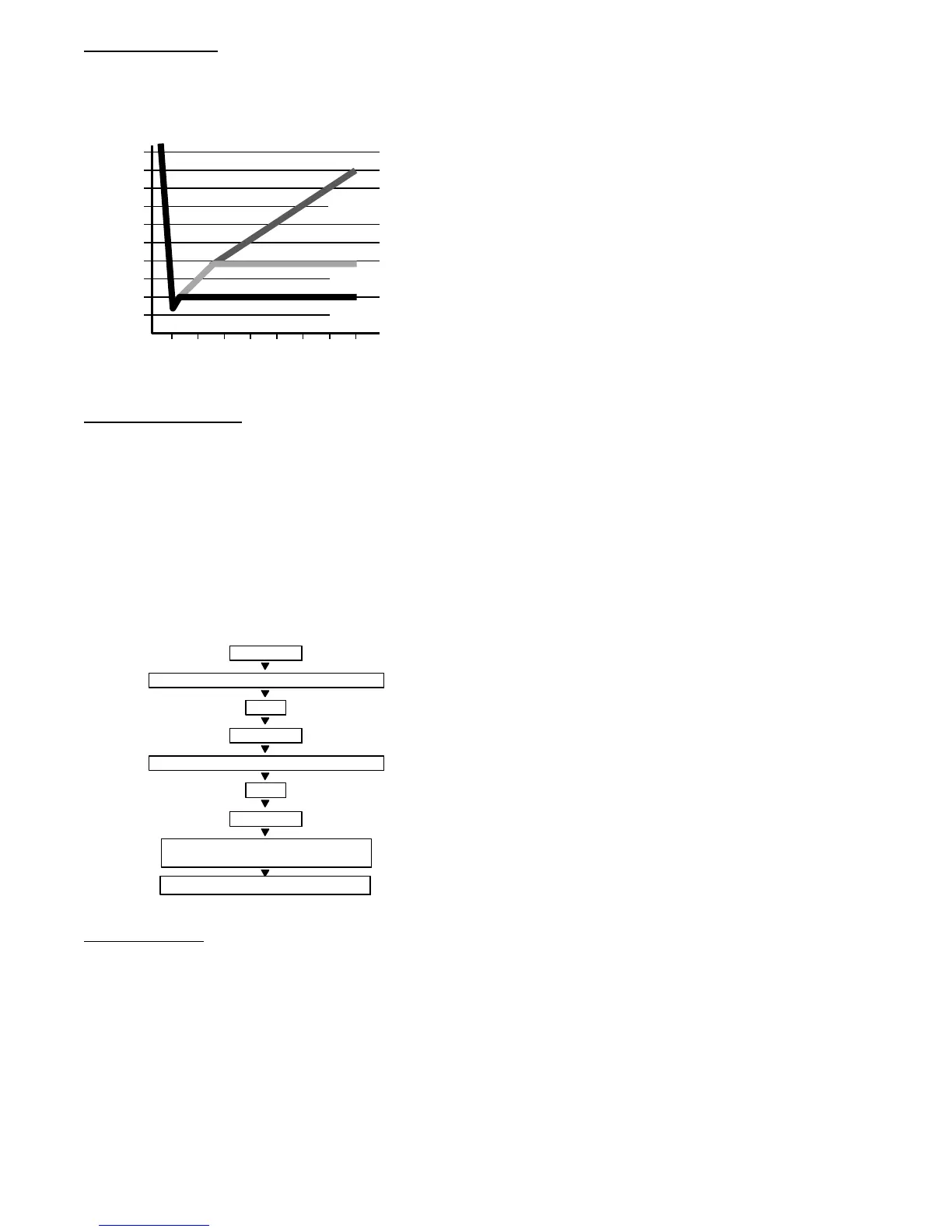

Triple Evacuation

Method

The triple evacuation process should be used in accordance with

the following figure. Refer to Fig. 17 and proceed as follows:

1 Pump system down to 500 microns and allow pump to con-

tinue operating for an additional 15 minutes.

2 Close service valves and shut off vacuum pump.

3 Connect a nitrogen cylinder and regulator to system and

open until system pressure is 2 psig.

4 Close service valve and allow system to stand for 1 hr .

During this time, dry nitrogen will be able to diffuse

throughout the system absorbing moisture.

5 Repeat this procedure as indicated in Fig. 17. The system is

freed of any contaminants and water vapor .

CHECK FOR TIGHT, DRY SYSTEM

(IF IT HOLDS DEEP VACUUM)

EVACUATE

BREAK VACUUM WITH DRY NITROGEN

WAIT

EVACUATE

RELEASE CHARGE INTO SYSTEM

BREAK VACUUM WITH DRY NITROGEN

EVACUATE

WAIT

Fig. 17 – Triple Evacuation Method

Final Tubing

Check

IMPORTANT: Check to be certain factory tubing on both

indoor and outdoor unit has not shifted during shipment.

Ensure tubes are not rubbing against each other or any sheet

metal. Pay close attention to feeder tubes, making sure wire ties

on feeder tubes ar e secure and tight.

CONTROL SYSTEM

The 40GRQ/ 38GRQ unit is equipped with a microprocessor

control to perform two functions:

1 Provide safety for the system

2 Control the system and provide optimum levels of comfort

and efficiency.

The main microprocessor is located on the control board of

outdoor unit. Outdoor and indoor units have thermistors used to

monitor the system operation to maintain the unit within acceptable

parameters and control the operating mode.

SYSTEM SAFETIES

3MinuteTimeDelay

In order to protect the compressor, there is a 3 minute delay on

break even if the control is calling for heating or cooling. The

compressor will have an additional 1 minute delay when powering

the unit on for the first time, or after a power failure.

Compressor Top Temperature Protection

The unit will stop working when the compressor top temperature

protector cuts off, and will restart after the compressor top

temperature protector restarts.

Compressor Discharge Temperature Protection

When the compressor discharge temperature reaches a higher one

than in normal operation, the running frequency will be limited

based on the algorithm presented below:

- When discharge B

208_F, prohibit increasing frequency

- When discharge B

217_F, prohibit decreasing frequency

- When discharge B

230_F, compressor stop operation

- When discharge B≤194_F, protection is released.

— If the compressor discharge temperature is lower than

194_F(90_C), there is no limit in the frequency.

— If this value is between 194_F and 221_F

(90<T5<105_C), the compressor will continue running

at the current frequency.

— If this value is now between 221_F and 239_F

(105<T5<115_C), the frequency will decrease to a lower

level every 3 minutes.

— When the compressor discharge temperature reaches a

value higher than 239_F(115_C), and has been running

at this condition for 5 seconds, the compressor stops.

Fan Speed Protection

When indoor fan speed is below 300RPM for a specific amount of

time the unit stops and the LED displays the failure.

Inverter Module Protection

The Inverter module is protected for abnormalities in current,

voltage and temperature. If abnormal values of any of these take

place, the corresponding code will be displayed in the indoor unit

and the unit will stop.

Indoor Fan Delayed Operation

Whe n the unit st arts up, the louve r will be active imme diately and the

indoor fa n will operate 10s later. If the operating mode is heati ng, the

indoor fa n will also be controll ed by the anti-col d blow functi on.

Loading...

Loading...