6

INSTALLATION

Step 1 — Unpack and Inspect Units —

Units are

packaged for shipment to avoid damage during normal transit

and handling. It is the receiving party’s responsibility to inspect

the equipment upon arrival. Any obvious damage to the carton

and/or its contents should be reported on the bill of lading and a

claim should be filed with the transportation company and the

factory. The unit should always be stored in a dry place and in

the proper orientation as marked on the carton.

After determining the condition of the carton exterior, carefully

remove each unit from carton and inspect for hidden damage.

Check to make sure that items such as thermostats and

controllers are accounted for whether packaged separately or

shipped at a later date. Any hidden damage should be recorded,

a claim should be filed with the transportation company, and

the factory should be notified. If a claim for shipping damage is

filed, the unit, shipping carton, and all packing must be retained

for physical inspection by the transportation company. All units

should be stored in the factory shipping carton with internal

packaging in place until installation.

PROTECTING UNITS FROM DAMAGE — Do not apply

force or pressure to the coil, piping, or drain stub-outs during

handling. All units should be handled by the chassis or as close

as possible to the unit mounting point locations.

Unit must always be properly supported. Temporary supports

used during installation or service must be adequate to hold

unit securely. To maintain warranty, protect units against

hostile environments (such as rain, snow, or extreme

temperature), theft, vandalism, and debris on jobsite.

Equipment covered in this manual is not suitable for outdoor

installations. Do not allow foreign material to fall into drain

pan. Prevent dust/debris from being deposited on motor, fan

wheels, and coils. Failure to do so may have serious adverse

effects on unit operation, and in case of motor and blower

assembly, this may result in immediate or premature failure.

Failure of any unit caused by deposits of foreign material on

motor or blower wheels will not be covered by manufacturer’s

warranty. Some units and/or job conditions may require some

form of temporary covering during construction.

PREPARING JOBSITE FOR UNIT INSTALLATION —

To save time and to reduce the possibility of costly errors, set

up a complete sample installation in a typical room at jobsite.

Check all critical dimensions such as pipe, wire, and duct

connections requirements. Refer to job drawings and product

dimension drawings as required. Instruct all trades in their

parts of the installation. Units must be installed in compliance

with all applicable local code requirements.

IDENTIFYING AND PREPARING UNITS — Be sure

power requirements match available power source. Refer to

unit nameplate and wiring diagram. In addition:

• Check all tags on unit to determine if shipping screws are

to be removed. Remove screws as directed.

• Rotate fan wheel by hand to ensure that fan is

unrestricted and can rotate freely. Check for shipping

damage and fan obstructions. Adjust blower motor as

required.

Step 2 — Position the Unit

Install unit in a location that meets the following requirements:

• Allow adequate space for installation, service clearance,

piping and electrical connections, and necessary

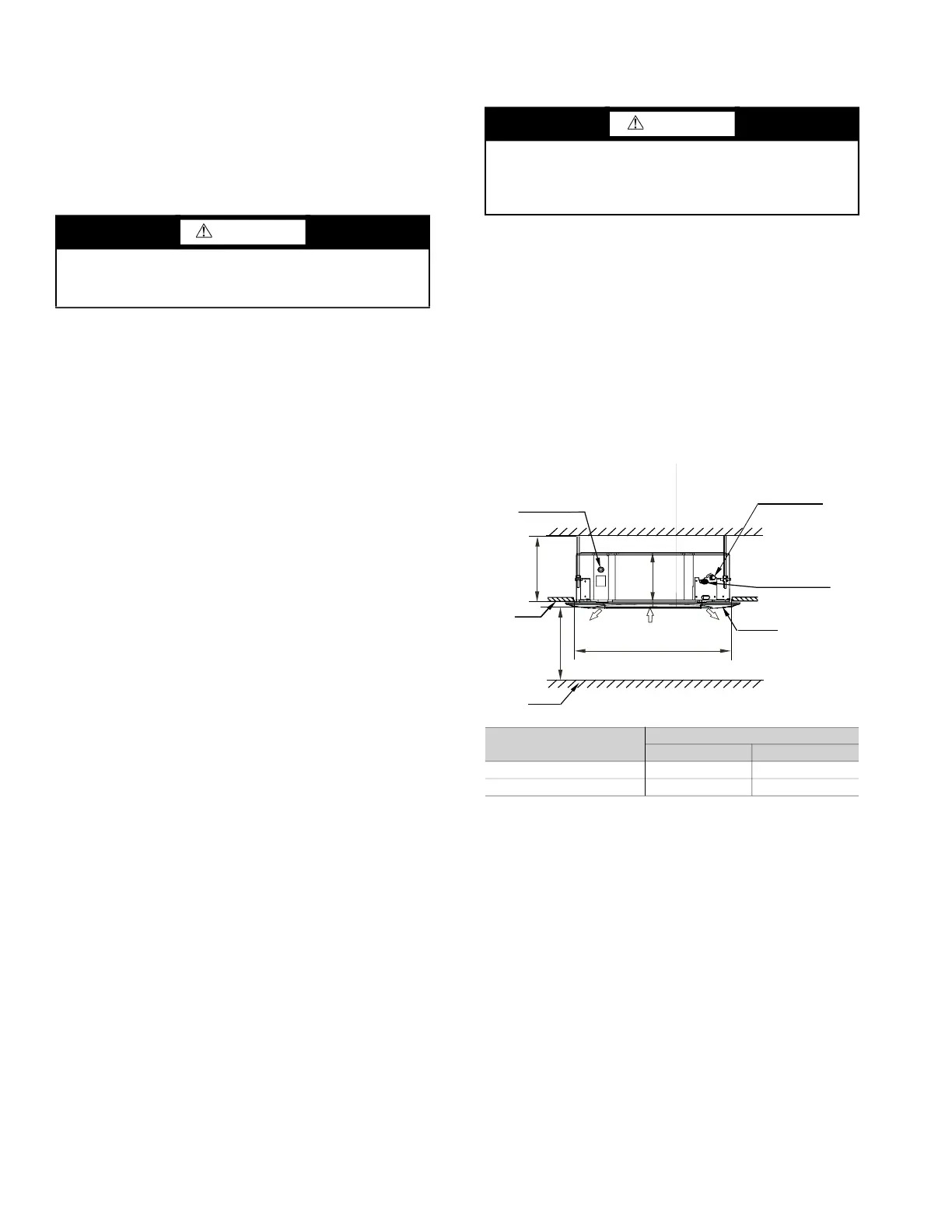

ductwork. For specific unit dimensions, refer to Table 1

and Fig. 2. Allow clearance according to local and

national codes.

• Confirm that the ceiling is able to support the weight of

the unit. See Table 1 for nominal weight.

• There should be enough room within the false ceiling for

installation and maintenance. See Fig. 3 below.

• The false ceiling should be horizontal and leveled.

• Install the unit in a location within the room that allows

uniform air flow in all directions.

Fig. 3 —False Ceiling Installation

Select the unit position with the following points in mind:

• The unit should be installed in a position that is suitable

to support the total weight of the unit, refrigerant piping,

and condensate.

• Proper access should be provided for maintenance for

refrigerant piping, EEV (electronic expansion valve),

electrical box, and condensate pump. A 2-ft clearance is

recommended all around the unit.

• The unit should be at least 3-

1

/

4

feet from a wall or

similar obstruction. See Fig. 4 below.

CAUTION

To avoid equipment damage, do not lift unit by the drain

pipe or refrigerant piping. The unit should be lifted using

the mounting brackets.

DANGER

Units must not be installed where they may be exposed to

potentially explosive or flammable atmosphere. If this

instruction is not followed exactly, a fire or explosion may

result, causing property damage, injury, or loss of life.

40VMF UNIT SIZE

DIMENSION (in.)

A H

009-015 9 10-

1

/

4

018-048 11-

3

/

4

13

A

H

>8-1/4 ft.

Connect to the outlet

of

drainage pipe

Connection port of

(Gas side)

refrigerant pipe

(Liquid side)

Connection port

of refrigerant pipe

Floor

Ceiling

Panel

Air outlet Air inlet

2-7/8 ft. (Ceiling hole)

Air outlet

Loading...

Loading...