21

GUIDE SPECIFICATIONS

Single-- Packaged Air Conditioner System

Constant Volume Application

HVAC Guide Specifications

Size Range: 2to4Tons,NominalCooling

Model Number: 50GL--A

Part 1 — General

SYSTEM DESCRIPTION

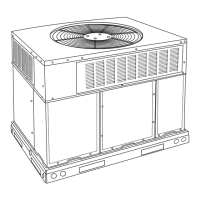

Outdoor rooftop mounted or ground mounted, electric cooling

unit utilizing a hermetic scroll compressor for cooling duty.

Unit shall discharge supply air vertically or horizontally as

shown on contract drawings. Condenser fan/coil section shall

have a draw-- thru design with vertical discharge for minimum

sound levels.

QUALITY ASSURANCE

B. Unit shall be tested in accordance with AHRI Standards

210/240 and 270.

C. Unit shall be designed in accordance with UL Standard

1995 and IEC 60335 -- 1.

D. Roof curb shall be designed to conform to NRCA

Standards.

E. Insulation and adhesives shall meet NFPA 90A

requirements for flame spread and smoke generation.

F. Cabinet insulation shall meet ASHRAE Standard 62P.

DELIVERY, STORAGE AND HANDLING

Unit shall be stored and handled per manufacturer’s

recommendations.

Part 2 — Products

EQUIPMENT

A. General:

Factory--assembled, single--piece, heating and cooling unit.

Contained within the enclosure shall be all factory wiring,

piping, controls, refrigerant charge with R -- 410A refrigerant,

and special features required prior to field start--up.

B. Unit Ca binet:

1. Unit cabinet shall be constructed of phosphated,

zinc--coated, pre--painted steel capable of with--standing 500

hours in salt spray.

2. Normal service shall be through a single removable cabinet

panel.

3. The unit shall be constructed on a rust resistant unit base

that has an externally trapped, integrated sloped drain.

4. Evaporator fan compartment top surface shall be insulated

with a minimum 1/2--in. (12.7 mm) thick, flexible

fiberglass insulation, coated on the air side and retained by

adhesive and mechanical means. The evaporator wall

sections will be insulated with a minimum semi--rigid foil--

faced board capable of being wiped clean. Aluminum foil--

faced fiber glass insulation shall be used in the entire indoor

air cavity section.

5. Unit shall have a field -- supplied condensate trap.

C. Fans:

1. The evaporator fan shall be direct-- drive multi -- speed motor

and control, as shown on equipment drawings.

2. Fan wheel shall be made from steel, be double--inlet type

with forward curved blades with corrosion resistant finish.

Fan wheel shall be dynamically balanced.

3. Condenser fan shall be direct drive propeller type with alu-

minum blades riveted to corrosion resistant steel spiders, be

dynamically balanced, and discharge air vertically.

D. Compressor:

1. Fully hermetic compressors with factory--installed vibration

isolation.

2. Scroll compressors shall be standard on all units.

E. Coils:

Evaporator and condenser coils shall have aluminum plate fins

mechanically bonded to seamless copper tubes with all joints

brazed. Tube sheet openings shall be belled to prevent tube

wear .

F. Refrigerant Components:

Refrigerant expansion device shall be of the fixed orifice type.

G. Filters:

Filter section shall consist of field--installed, throwaway, 1--in.

(25 mm) thick fiberglass filters of commercially available

sizes.

H. Controls and Safeties:

1. Unit controls shall be complete with a self--contained low

voltage control circuit.

2. Compressors shall incorporate a solid-- state compressor

protector that provides reset capability.

I. Operating Characteristics:

1. Unit shall be capable of starting and running at 125_F

(51_C) ambient outdoor temperature (except 48 size shall

be capable of starting and running at 115_ F(46_C)

2. Compressor with standard controls shall be capable of op-

erationdownto40_F(4_C) ambient outdoor temperature.

3. Units shall be provided with fan time delay to prevent cold

air delivery before the heat exchanger warms up.

J. Electrical Requirements:

All unit power wiring shall enter the unit cabinet at a single

location.

K. Motors:

1. Compressor motors shall be of the refrigerant-- cooled type

with line--break thermal and current overload protection.

2. All fan motors shall have permanently lubricated bearings,

and inherent, automatic reset, thermal overload protection.

L. Special Features:

1. Thermostat:

To provide for one--stage heating and cooling in addition

manual or automatic changeover and indoor fan control.

2. Crankcase Heater:

Shall provide anti--floodback protection for low-- load cool-

ing applications.

3. Electric Heaters:

a. Electric heater shall be availabel as a field--installed

option.

b. Heater elements shall be open wire type, adequately

supported and insulated with ceramic bushings.

c. Electric heater packages must provide single point

power connection capability.

50GL--A

Loading...

Loading...