14

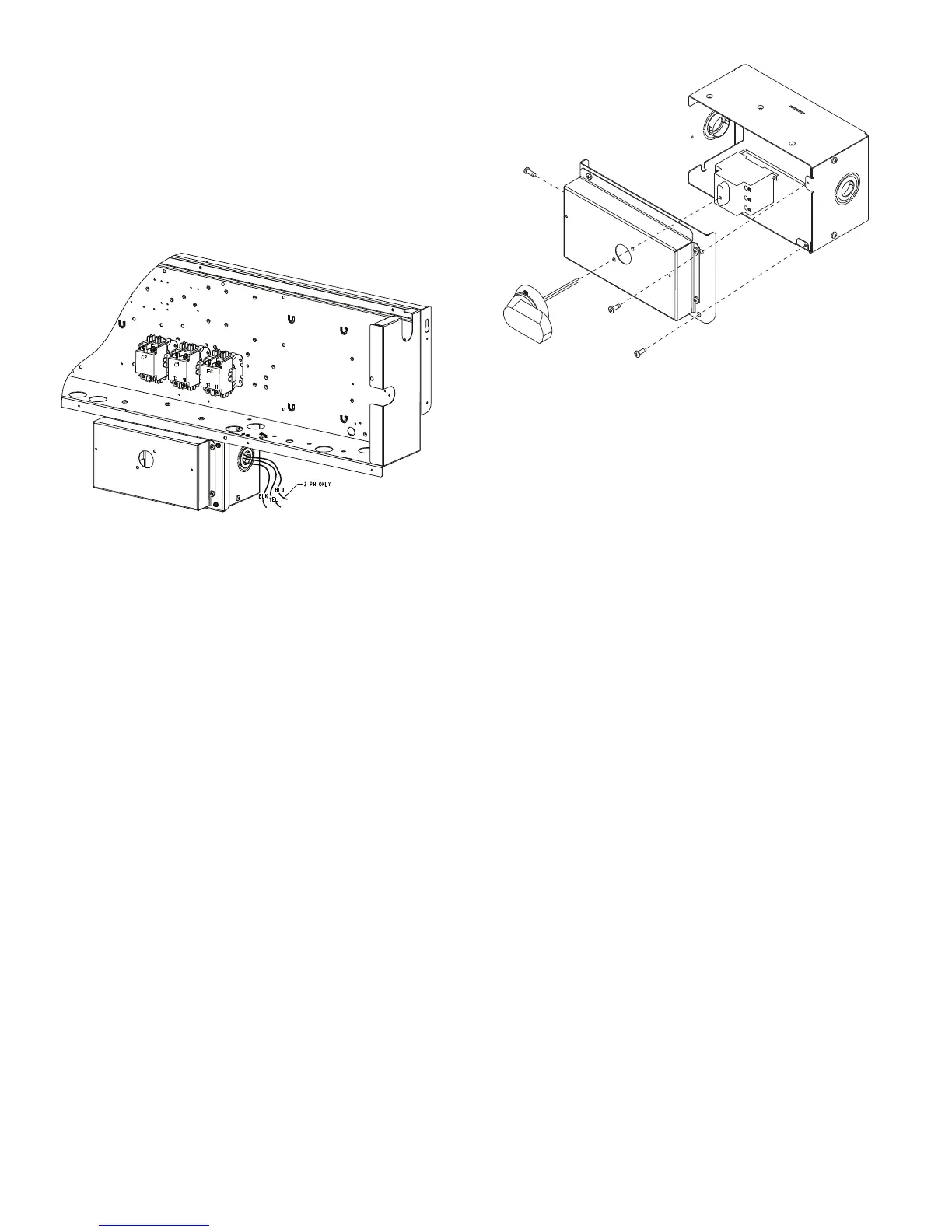

UNITS WITH FACTORY-INSTALLED NON-FUSED DIS-

CONNECT

The factory-installed option non-fused disconnect (NFD)

switch is located in a weatherproof enclosure located under

the main control box. The manual switch handle and shaft are

shipped in the disconnect enclosure. Assemble the shaft and

handle to the switch at this point. Discard the factory test

leads (see Fig. 18).

Connect field power supply conductors to LINE side termi-

nals when the switch enclosure cover is removed to attach the

handle.

Fig. 20 — Location of Non-Fused Disconnect

Enclosure

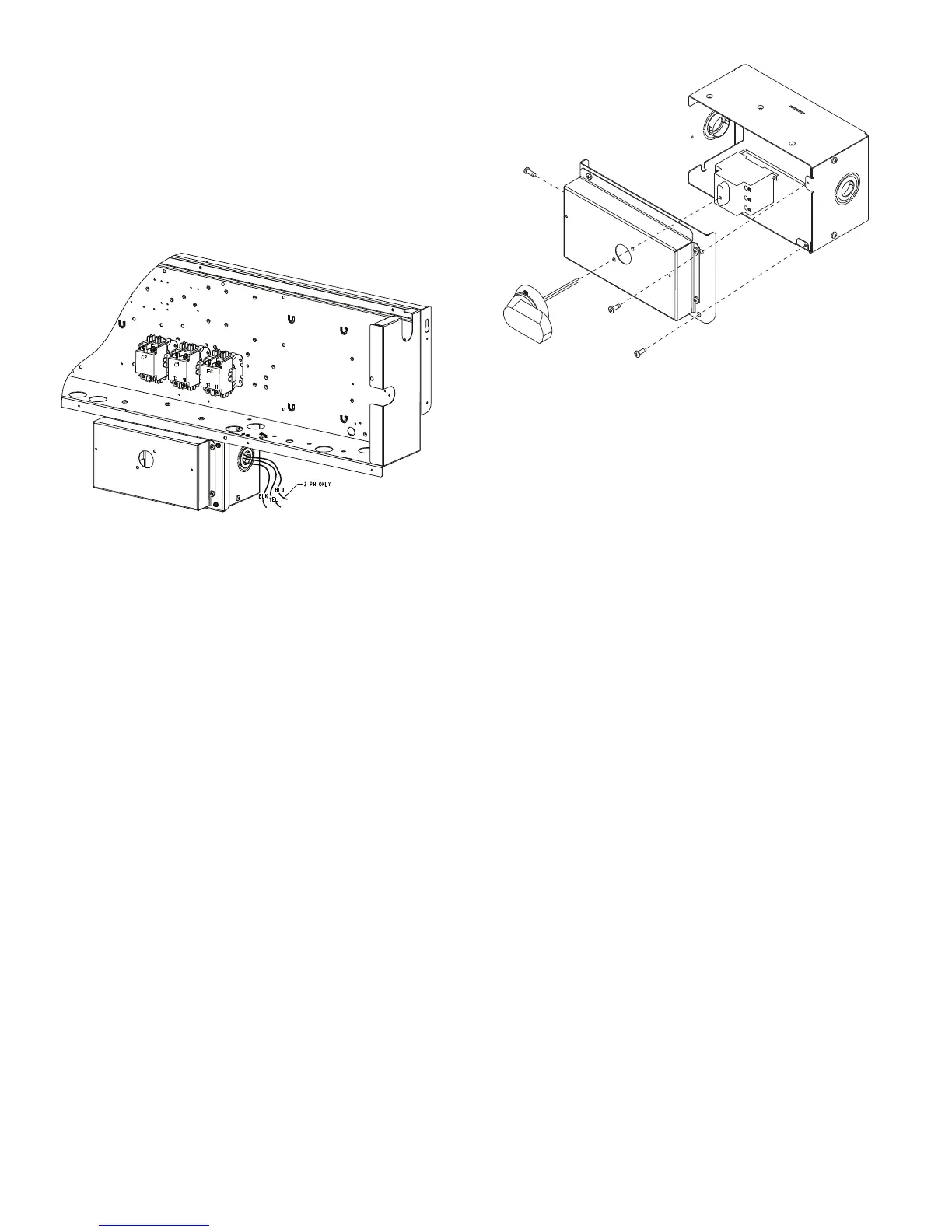

To field install the NFD shaft and handle:

1. Remove the unit front panel (see Fig. 2).

2. Remove (3) hex screws on the NFD enclosure — (2) on

the face of the cover and (1) on the left side cover.

3. Remove the front cover of the NFD enclosure.

4. Make sure the NFD shipped from the factory is at OFF

position (the arrow on the black handle knob is at OFF).

5. Insert the shaft with the cross pin on the top of the shaft

in the horizontal position.

6. Measure from the tip of the shaft to the top surface of the

black pointer; the measurement should be 3.75 to 3.88 in.

(95 to 99 mm).

7. Tighten the locking screw to secure the shaft to the NFD.

8. Turn the handle to the OFF position with red arrow

pointing at OFF.

9. Install the handle on to the painted cover horizontally

with the red arrow pointing to the left.

10. Secure the handle to the painted cover with (2) screws

and lock washers supplied.

11. Engaging the shaft into the handle socket, re-install (3)

hex screws on the NFD enclosure.

12. Re-install the unit front panel.

Fig. 21 — Handle and Shaft Assembly for NFD

UNITS WITHOUT FACTORY-INSTALLED NON-FUSED

DISCONNECT

When installing units, provide a disconnect switch per NEC

(National Electrical Code) of adequate size. Disconnect siz-

ing data is provided on the unit informative plate. Locate dis-

connect sizing data on unit cabinet or within sight of the unit

per national or local codes. Do not cover unit informative

plate if mounting the disconnect on the unit cabinet.

ALL UNITS

All field wiring must comply with NEC and all local codes.

Size wire based on MCA (Minimum Circuit Amps) on the

unit informative plate. See Fig. 18 and the unit label diagram

for power wiring connections to the unit power terminal

blocks and equipment ground. Maximum wire size is #2 ga

AWG (copper only) per pole on contactors.

Provide a ground-fault and short-circuit over-current protec-

tion device (fuse or breaker) per NEC Article 440 (or local

codes). Refer to unit informative data plate for MOCP (Maxi-

mum Over-current Protection) device size.

All field wiring must comply with the NEC and local require-

ments.

All units except 208/230-v units are factory wired for the

voltage shown on the nameplate. If the 208/230-v unit is to be

connected to a 208-v power supply, the control transformer

must be rewired by moving the black wire with the

1

/

4

-in. fe-

male spade connector from the 230-v connection and moving

it to the 200-v

1

/

4

-in. male terminal on the primary side of the

transformer. Refer to unit label diagram for additional infor-

mation. Field power wires will be connected line-side pres-

sure lugs on the power terminal block or at factory-installed

option non-fused disconnect.

NOTE: Check all factory and field electrical connections for

tightness.

Loading...

Loading...