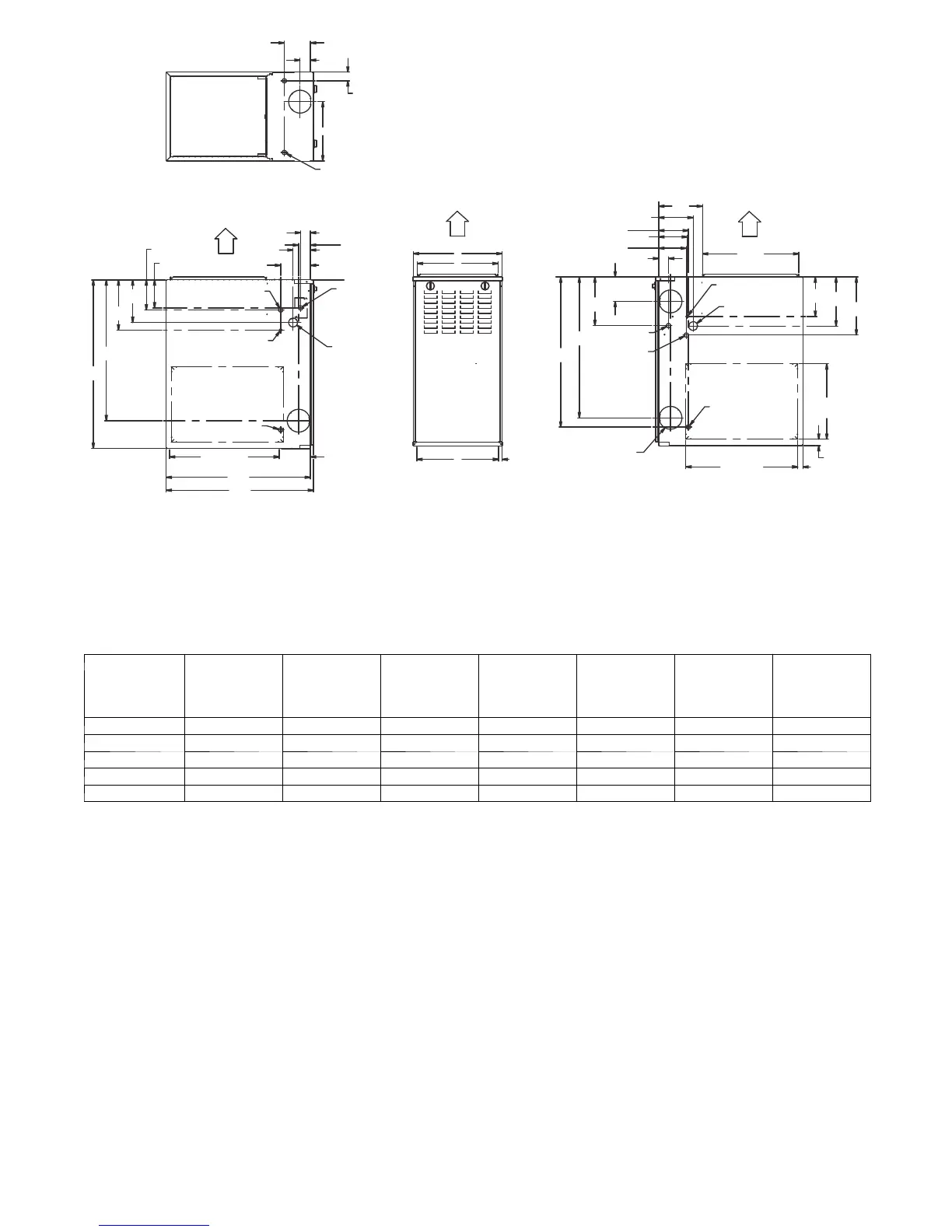

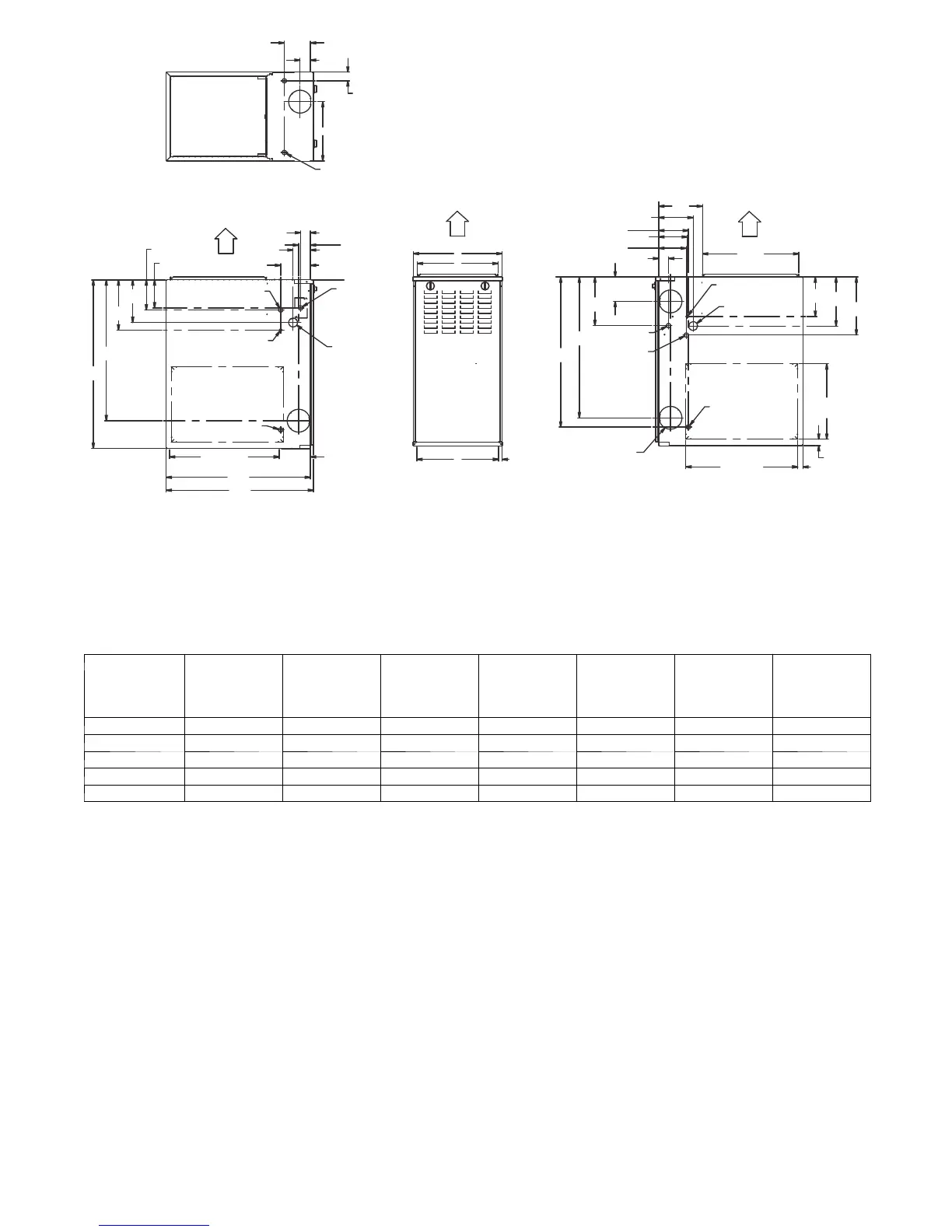

5

A

[736.9]

29

Ø7/8

[22.2]

ACCESSORY

5 15/16

[150.7]

28.39

[721.2]

Ø7/8

[22.2]

ACCESSORY

14 7/8

[337.3]

(BOTH SIDES)

Ø7/8

[22.2]

ACCESSORY

Ø7/8

[22.2]

ACCESSORY

Ø1 3/4

[44.5]

GAS ENTRY

Ø1/2

[12.7]

THERMOSTAT WIRE ENTRY

22 1/16

[560]

SIDE INLET

(BOTH SIDES)

11 7/16

[290.7]

9 11/16

[245.4]

[197.8]

7 13/16

Ø7/8

[22.2]

J.BOX PROVISION

Ø7/8

[22.2]

JUNCTION BOX

LOCATION

Ø1 3/4

[44.5]

GAS ENTRY

1 15/16

[49.2]

[25.4]

1 1/4

[31.8]

29 9/16

[750.7]

1 15/16

[49.2]

5 5/8

[143.3]

5 7/16

[138.5]

6 13/16

[172.3]

Ø1/2

[12.7]

THERMOSTAT WIRE ENTRY

19

[481.7]

OUTLET

21.6

[549.5]

BOTTOM INLET

33 1/4

[843.9]

9 9/16

[243.3]

3/4

[19.1]

5 7/8

[148.5]

3 7/16

[86.8]

9 7/8

[250.7]

27 3/4

[704.7]

2 5/16

[59]

FRONT OF CASING

TOP OF CASING

4 13/16

[122.2]

27 3/4

[704.7]

5 7/8

[148.5]

8 5/8

[219]

5 1/2

[140.3]

8 7/16

[213.5]

FRONT OF CASING

TOP OF CASING

6.1

[155.7]

2 1/16

[51.6]

5.1

[130.5]

1.7

[43.5]

Ø7/8

[22.2]

ACCESSORY (2)

AIR FLOW

AIR FLOW

BOTTOM RETURN

WIDTH

AIR FLOW

KNOCK OUTS FOR

VENTING(5

PLACES)

A10290

NOTES:

1. Two additional 7/8 ---in. (22 mm) diameter holes are located in the top plate.

2. Minimum return ---air openings at furnace, based on metal duct. If flex duct is used, see flex duct manufacturer’s recommendations for equivalent diameters.

a. For 800 CFM---16---in. (406 mm) round or 14 1/2 x 12---in. ( 368 x 305 mm) r e ctangle.

b. For 1200 CFM ---20 ---in. (508 mm) roun d or 14 1/2 x 19 1/2 ---in. (368 x 495 mm) rectangle.

c. For 1600 CFM ---22 ---in. (559 mm) roun d or 14 1/2 x 22 1/16 ---in. (368 x 560mm) rectangle.

d. For airflow requ irements above 1800 CFM, see Air Delivery table in Product Data literature for specific use of single side inlets. The use of both sideinlets,

a combination of 1 side and the bottom, or the bottom only will ensure adequate r etu r n air openings for airflow r equirements above 1800 CFM.

A B C D

FURNACE SIZE

CABINET

WIDTH

OUTLET

WIDTH

TOP AND

BOTTOM FLUE

COLLAR

BOTTOM

INLET WIDTH

VENT

CONNECTION

SIZE

SHIP WT. LB

(KG)

ACCESSORY

FILTE R MEDIA

CABINET SIZE

045---12/036045 14-3/16 (360) 12-9/16 (319) 9-5/16 (237) 12---11/16 (322) 4 (102) 107 (49) 16 (406)

070---16/048070 17 --- 1/2 (445) 15-7/8 (403) 11-9/16 (294) 16 (406) 4 (102) 126 (57) 16 (406)

090---16/048090 21 (533) 19-3/8 (492) 13-5/16 (338) 19---1/2 (495) 4 (102) 140 (64) 20 (506)

110---22/066110 21 (533) 19-3/8 (492) 13-5/16 (338) 19---1/2 (495) 4 (102) 152 (69) 20 (506)

135---22/066135 24-1/2 (622) 22-7/8 (581 15-1/16 (383) 23 (584) 4 (102) 163 (74) 24 (610)

*135 size furn aces require a 5 or 6 ---in. (127 or 152 mm) vent. Use a vent adapter between furnace an d ven t stack. See Installation Instructions for complete

installation requirements.

Fig. 3 -- Dimensional Drawing

4. If you touch ungrounded objects (and recharge your body

with static electricity), firmly touch a clean, unpainted

metal surface of the furnace again before touching control

or wires.

5. Use this procedure for installed and uninstalled (ungroun-

ded) furnaces.

6. Before removing a new control from its container, dis-

charge your body’s electrostatic charge to ground to pro-

tect the control from damage. If the control is to be in-

stalled in a furnace, follow items 1 through 4 before

bringing the control or yourself in contact with the fur-

nace. Put all used and new controls into containers before

touching ungrounded objects.

7. An ESD service kit (available from commercial sources)

mayalsobeusedtopreventESDdamage.

LOCATION

GENERAL

This multipoise furnace is shipped in packaged configuration.

Some assembly and modifications are required when used in any

of the four applications shown in Fig. 4.

NOTE: For high--altitude installations, the high--altitude

conversion kit MUST be installed at or above 5500 ft. (1676 M)

above sea level. Obtain high--altitude conversion kit from your

area authorized distributor.

Loading...

Loading...